Polyfoam was and remains one of the most popular and demanded thermal insulation materials used in construction. Due to its excellent thermal insulation characteristics, it is used for insulation of residential buildings, garages, warehouses and other structures. In the process of heat insulation works, as a rule, a crate is used, into which sheets of foam plastic are laid. But it is not always possible to install the crate, plus this is an additional job that requires time and money. Is it possible to heat a wall without using a crate? This method is widely used - you can simply paste sheets of foam on the wall. How to glue polystyrene, how to do it, what tools are used at the same time - all these issues we will consider in this publication.

Content

It is necessary to realize that the foam is a rather gentle material, and the incorrectly selected glutinous mixture can simply destroy it. There is another problem that can be encountered when trying to glue the foam to the wall - a low degree of stickiness. Not every glue is able to reliably and permanently attach the foam to a bare concrete surface. And a lot of glue compounds are simply incompatible with polystyrene. Therefore, you should not experiment, because such amateur performance can be detrimental to your wallet.

So what to put foam on concrete? There are several ways to securely glue the foam to a concrete surface.

Method No. 1. Fastening with glue

To carry out the work you will need:

- Glue for foam plastic.

- Primer solution.

- Cement solution.

- Spatula, better comb.

- Styrofoam.

- Electrodrill, nozzle-mixer.

Before starting work, it is necessary to thoroughly clean the surface of the wall, on which the foam will be glued. It is necessary to remove all contaminants - dust, grease stains, cut off strongly protruding tubercles and small irregularities. If a layer of the concrete crumbles or lags behind a section of the concrete, this area must be removed and the damaged area should be thoroughly primed. Cracks and deep cavities need to be leveled with cement mortar.

The glue intended for a foam is almost always realized as a dry mix. It must be diluted with warm water to a consistency of thick sour cream. In this case, the glue must not contain lumps. For this, it is best to use a drill with a special nozzle, as we noted above. The finished glutinous mixture should be infused for about 5 hours, after which it is again mixed. After that, the glue must be completely consumed within 2 hours.

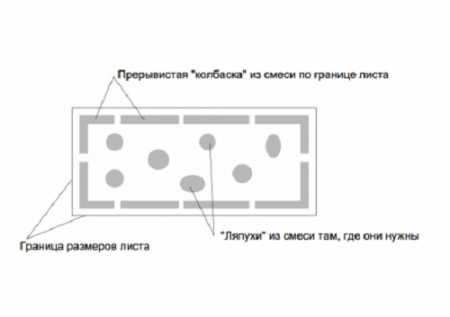

How correctly to glue foam? They do it differently, it all depends on how smooth the wall surface is. So, if the wall has large small irregularities, up to five centimeters, then the glue is applied to the foam plastic strips. Thus, from outside the foam plastic plate, excess air will escape. When there are irregularities up to one and a half centimeters on the wall, the glue is applied with a strip with an indent from the edge approximately 2 centimeters. Some amount of glue must be applied to the center of the sheet. Strips of glue, as in the previous case, should have small gaps, so as not to form an air cork.

When there are subtle irregularities on the wall, not exceeding 3 millimeters, the adhesive is applied with a notched trowel. After that, the plate is pressed firmly against the surface. Excess glue is carefully removed with a damp cloth.

Important point: the foam plastic absorbs moisture very badly, so the glue should not contain water, otherwise the insulation will fall off the wall very soon.

Method №2 Fastening with dowels

For work you will need:

- Dowels.

- Styrofoam.

- Sealant.

In this case, the sheet of foam is fastened with dowels in five places - in the corners and in the center. Corner dowels fix the joints of the sheets. The joints are sealed with sealant to avoid heat loss. To fix the foam on the concrete surface three anchors are enough.

Work starts from the bottom, attaching the so-called starting row of foam. Between the sheets leave a small gap of about 3 millimeters. This is necessary to avoid deformation at high humidity and temperature changes. Fixing foam on the dowel is the simplest and cheapest way.

Method number 3. Fastening with liquid nails

Materials required for work:

- Styrofoam.

- Liquid Nails.

- Protective gloves.

Liquid nails are quite strong glue, well tolerated by high temperature and humidity changes. It quickly hardens even in a humid environment, concrete and foam are very well fastened with this glue. Liquid nails do not need to be applied to the entire surface of the sheet, just make a few small points. Before buying glue, carefully study its characteristics, as some glutinous mixtures can not be used when working with polystyrene. Liquid nails contain components that have a sufficiently high toxicity, so it is necessary to work in gloves.

When you need to glue the foam to the ceiling, take into account the time during which the adhesive reliably seizes. Different brands of liquid nails freeze at different rates, but the total setting time usually does not exceed half an hour. Therefore, for 30 minutes you have to press a sheet of foam to the surface of the ceiling. Work begins with the cleaning of the surface from contamination. The surface must be dry. On the foam sheet, several points or strips of glue are applied, pressed against the wall or ceiling for a while.

If for some reason you are not satisfied with these two ways of fixing the foam, there is one more.

Method No. 4. Foam fixing

This is a rather popular way of fixing foam. It is not a usual foam, but a special foam for the foam.

This material has several significant advantages, which is why it is often preferred:

- Very fast and easy installation.

- The glue very firmly connects the foam to the concrete surface.

- Low cost glue.

- Glue-foam can be used to seal joints between sheets.

- Mounting gun for applying glue.

Depending on the field of application, glue-foam can be of several types:

- Foam for a foam block. This adhesive has the highest strength characteristics, it can even be used instead of mortar for masonry.

- Glue foam for foam. It is used for internal heat insulation works, it is resistant to fire. Of the disadvantages - it does not work well on smooth surfaces.

Foam, which is used to fix the foam, is inexpensive and has small retention abilities. But still with the help of this glue it is possible to fix a sheet of foam almost on any surface - from wood to concrete and metal. It is only necessary to clean and slightly moisten the surface before work to improve adhesion. Glue-foam is applied to the wall or polystyrene with small spots, preferably staggered. After that, you need to wait a bit and press the foam firmly against the wall. Time is kept for the glue to absorb a little. Work with the application of glue-foam is carried out at a temperature of at least 20 degrees Celsius. In the process of work, do not arrange long smoke breaks, as the foam in the mounting gun quickly freezes.

If excess foams begin to appear in the joints between the foam sheets, they must be immediately removed with a special solvent.

You can also glue the foam with mounting foam. But for working with ordinary foam it will take a lot longer, in addition, it is heavily swollen, which can lead to deformation of the foam and divergence of the joints.

We apply foam to the facade

The fixing of the foam on the outside of the building is very different from the interior work. Consider the option of mounting using the products of the brand "Ceresit" in the idea of step by step instructions.

step one. foundation preparation

We clean the base, if necessary, remove pieces of stucco or other coating, clean and ground the damaged areas. If there are irregularities exceeding one and a half centimeters, they must be eliminated with a mixture of Ceresit CT-29. If the surface has poor adhesive properties, it must be thoroughly primed with a deeply penetrating mixture of Ceresit CT-17.

step two. attach the profile to the base

The width of the profile should be equal to the thickness of the foam. In the basement of the building along the entire perimeter the starting profile is established. Mount it with dowels, which are located at a distance of about 40 centimeters.

step three. we put glue, we fasten plates of foam plastic

Ceresit CT-85 adhesive solution is used for fixing the insulation, as well as for creating a protective layer. But this mixture is quite expensive, so from a financial point of view it's more profitable to use Ceresit-83 glue.

After the glue is prepared, it is applied to the foam sheet with "bug-eyed" spots. Foam is pressed against the surface, carefully set, slightly pressing on the corners of the sheet.

step four. we fix foam with dowels

The necessary number of dowels, or as they are called, "umbrellas", are calculated in different ways. But most often use four "umbrellas" per one square meter. If the wall is concrete or brick, the length of the dowel must be greater than the thickness of the foam sheet by 50 mm.