The term "construction on Canadian technology" appeared in the process of adopting the rules "Design and construction of energy efficient single-family houses with a wooden frame." This set of rules was developed on the basis of Canada's National Housing Code. It should be noted that it is still more correct to call this technology of building a frame house not "Canadian", namely "frame", since, most likely, it appeared in the US. To put it simply, this technology is just a kind of frame construction technology, but only wooden structures are used. In our publication, we will consider all the pros and cons of using this method of housing construction, and also in general terms, consider the work process.

Content

Advantages and disadvantages of frame houses

advantages of wireframe technology

Frame houses are inexpensive. Let's say more - today this is the cheapest option for housing construction. One square meter of finished housing, including the foundation, roof, heating, electricity, internal work, will cost only 450-500 dollars. Approximately in the same amount will cost only a brick box with a foundation for traditional construction. Frame house is light, the load on the foundation is minimal. Houses built on Canadian technology have excellent thermal insulation. For comparison: in order to achieve the same characteristics of thermal conductivity, a brick wall should be built with a thickness of one and a half meters! Frame houses are built much faster than brick ones: the construction of a foundation, boxes and roof takes about 8 weeks. Savings on the foundation: instead of an expensive and labor-intensive traditional foundation, the technology of frame construction allows you to make an inexpensive columnar-ribbon foundation. The fire safety of a house is quite simple to provide with the help of a mass of modern inexpensive impregnations.

disadvantages of wireframe technology

The main drawback is the entrenched traditions and conservatism, nothing more. There are no really serious shortcomings. In an overwhelming number of cases, all the powerful "evidence" about the shortcomings of Canadian technology is brought by competitors who work by traditional methods. However, any construction technology has its pros and cons. We list the most basic, in our opinion, shortcomings: The need for a very high-quality and carefully thought-out ventilation system. This is not even a drawback, just the ventilation in the frame house should be better than in the brick, which, by the way, is often built at all without a ventilation system. High fire hazard of frame houses. It should be noted that rumors about the flammability of frame buildings are greatly exaggerated. Any buildings burn, and wireframes are no exception. But to protect against fire in the sale there are a lot of drugs, including for the impregnation of wooden structures. The disadvantage here is not in increased flammability, but in the need for additional costs for safety measures, fire retardant paints and impregnations. In addition, the generally accepted rules of fire safety have not been canceled: compliance with the simplest rules for the installation and operation of electrical wiring, compliance with fire requirements for the appliance of electrical appliances, stoves, fireplaces and chimneys, etc. When talking about Canadian homes, they often remember rodents. Well, the problem is urgent, but not more than for brick houses. Rodents are omnipresent, they will easily arrange moves in a brick building, and in a house from a cinder block, they will find weaknesses even in a monolithic house. But the rodents do not eat mineral wool and glass wool, however, they are coping well with polystyrene, arranging whole colonies inside the insulation. But with the modern variety of ways and means to combat rodents, they do not represent any serious danger. Limited number of storeys. Perhaps the only serious disadvantage of frame houses. Frame buildings in the vast majority of single-story, as the two-story frame house will cost at least, and even more brick, while losing such an important advantage as saving money.

Types and types of frame houses

frame-panel houses

According to the type of construction frame houses on Canadian technology can be conditionally divided into two categories: frame-frame and frame-panel. In particular, "panel houses" are more common in the northern regions. Another name is "Finnish house". Most often is a one-story building with a gable roof. Panels for Finnish houses are manufactured according to a ready-made standard design at factories. Manufacturers produce house parts in varying degrees of readiness: from the frame to fully finished wall panels, with inserted windows, utilities, floor slabs and roof parts. At the same time, the dimensions of all the elements correspond exactly to the design.  At the construction site, it remains only to assemble a finished house from this "designer". Elements simply connect with each other, which allows you to complete the construction in the shortest possible time. Frame-panel houses have a number of advantages. These houses are assembled very quickly - the box is installed for one week. As we already mentioned above, panels are manufactured in factories, while observing all the necessary requirements, so the finished products have high quality, which significantly extends the life of the finished housing.

At the construction site, it remains only to assemble a finished house from this "designer". Elements simply connect with each other, which allows you to complete the construction in the shortest possible time. Frame-panel houses have a number of advantages. These houses are assembled very quickly - the box is installed for one week. As we already mentioned above, panels are manufactured in factories, while observing all the necessary requirements, so the finished products have high quality, which significantly extends the life of the finished housing.  The main disadvantage when working with frame-panel houses is the need to attract a crane. Almost all the work on the construction of frame-panel houses are done by specialized firms, this kind of housing can not be built on their own. The sequence of works when erecting a skeleton-panel house is as follows:

The main disadvantage when working with frame-panel houses is the need to attract a crane. Almost all the work on the construction of frame-panel houses are done by specialized firms, this kind of housing can not be built on their own. The sequence of works when erecting a skeleton-panel house is as follows:

- The device is a lightweight foundation - tape or pile.

- Mounting frame from wooden trusses. Farms are also used as lags for the floor.

- Installation of panels according to the project.

- Roof and roof installation.

- Installation of all necessary communications.

- Finishing work.

In general, the construction of a frame-panel house takes 2-3 months.

frame-frame houses

The main advantage of this type of buildings is that when building a house you can use any project, including one developed independently. In addition, such a house can be built on its own. Frame-frame houses differ from the panels by the process of manufacturing and installing panels. So, when building a frame-frame house, first a foundation is made, a frame, a roof is mounted on it, and only after that thermal insulation works and carcass plating with sheet materials are made. All other construction and finishing works are carried out in the same way as in the construction of frame-panel buildings. If you build a frame house with your own hands, then you can manage about six months.

The main advantage of this type of buildings is that when building a house you can use any project, including one developed independently. In addition, such a house can be built on its own. Frame-frame houses differ from the panels by the process of manufacturing and installing panels. So, when building a frame-frame house, first a foundation is made, a frame, a roof is mounted on it, and only after that thermal insulation works and carcass plating with sheet materials are made. All other construction and finishing works are carried out in the same way as in the construction of frame-panel buildings. If you build a frame house with your own hands, then you can manage about six months.

Foundation

The house in which it is planned to live all year round, it is necessary to insulate properly. As a foundation for a frame-frame house, you can use a pile screw, columnar, or unclipped ribbon foundation. Considering the options for foundations, you need to consider the type of soil, as well as the number of storeys of the future house. For one floor there will be enough columnar foundation, even if the soil is not too dense. For the construction of a columnar foundation with a special drill make holes in the soil with a diameter of about 20 cm and a depth of up to a meter. Cuttings of asbestos pipes are installed in the finished grooves. Space around the pipe is sprinkled with fine gravel and sand and carefully compacted. Inside the pipe is filled with a strong cement mortar. At the same time, you do not need to wait until the solution is completely seized, you can continue working further.

Quite a lot of popularity is enjoyed by the pile foundation of screw, which can be done on its own without referring to professionals. All work on the installation of the screw foundation is best done manually, since the piles must be screwed strictly perpendicular to the ground, without the slightest deviation. Important point: the pile can be screwed into one place only once, so as not to disturb the density of the soil.

casing of a foundation

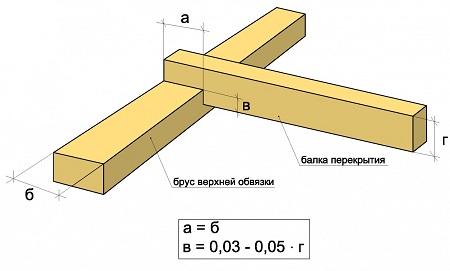

When erecting a frame-panel house, Finnish or Canadian technology is used. But regardless of what technology will be carried out construction work, the principle is almost the same. The basis is a frame, which can be both wooden and metal. But most often wood is used in making the frame.  For the binding of the frame used wooden bars section 15x15, 20x20 and 25x25 cm. Before putting the beam into work, it must be properly prepared - the material must be carefully dried and treated with an antiseptic.

For the binding of the frame used wooden bars section 15x15, 20x20 and 25x25 cm. Before putting the beam into work, it must be properly prepared - the material must be carefully dried and treated with an antiseptic.  The top part of each pile is covered with mastic, several layers of roofing material are laid on top. The processed bar is installed along the perimeter of the base. Between each other, the beams are fastened with nails, and the fastening screws are fastened to the concrete base with special fastening screws.

The top part of each pile is covered with mastic, several layers of roofing material are laid on top. The processed bar is installed along the perimeter of the base. Between each other, the beams are fastened with nails, and the fastening screws are fastened to the concrete base with special fastening screws.  On the finished piping lay the boards, overlapping the joints of the bars. On these boards in the future will be installed racks of the frame. The board must also be thoroughly impregnated with an antiseptic.

On the finished piping lay the boards, overlapping the joints of the bars. On these boards in the future will be installed racks of the frame. The board must also be thoroughly impregnated with an antiseptic.

The rough floor

For the device of the rough floor, it is advisable to use a non-edging board as the cheapest material. The board before work, do not forget to treat it with an antiseptic. Lags for the floor are attached to the bars of the straps with metal corners. The board is nailed to the logs with usual nails.

For the device of the rough floor, it is advisable to use a non-edging board as the cheapest material. The board before work, do not forget to treat it with an antiseptic. Lags for the floor are attached to the bars of the straps with metal corners. The board is nailed to the logs with usual nails.

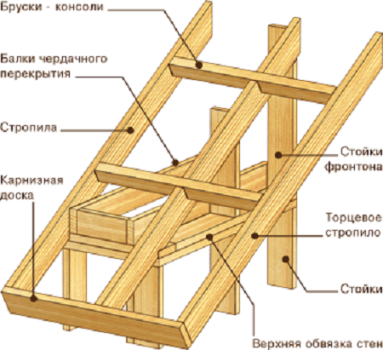

The process of mounting the frame, walls, ceiling

First, the frame racks are installed in all corners. Since the corner posts have the greatest load, they are attached with reinforced steel corners. After that, all the other racks are mounted. To the frame in the process of work is not loosened, it is fastened with jagged edges.  In the corners for the beams cuttings are made, in other places they are fastened with the help of self-tapping screws. To give the carcass an extra margin of safety, make diagonal cuts. In the process of building walls, do not forget the ceiling. The most optimal height is 2.5 meters. In this case, taking into account the decorating with finishing materials, the ceiling height will be at least 2.3 meters. During the installation of the walls, all necessary communications are immediately carried out, since in frame houses they are hidden inside the walls.

In the corners for the beams cuttings are made, in other places they are fastened with the help of self-tapping screws. To give the carcass an extra margin of safety, make diagonal cuts. In the process of building walls, do not forget the ceiling. The most optimal height is 2.5 meters. In this case, taking into account the decorating with finishing materials, the ceiling height will be at least 2.3 meters. During the installation of the walls, all necessary communications are immediately carried out, since in frame houses they are hidden inside the walls.  Ceiling beams are mounted in several ways: making cuttings using brackets or a metal corner.

Ceiling beams are mounted in several ways: making cuttings using brackets or a metal corner.  The mounting method is chosen depending on the mounting location. As a support for the ceiling beams serves as a bundling bar. Additionally, the beams are fixed with screws.

The mounting method is chosen depending on the mounting location. As a support for the ceiling beams serves as a bundling bar. Additionally, the beams are fixed with screws.

Roof installation

The rafter structure of the roof of the frame house is fixed with usual nails and for additional strength is covered with a board. The rafters are placed on the walls with a ledge of 20 centimeters. At the edges of the rafters nailed and additionally fastened with stalks.  After all the central parts of the rafter structure are installed, the ridge board is nailed. After that, the lath of the edging board is 1.5-2 cm thick.

After all the central parts of the rafter structure are installed, the ridge board is nailed. After that, the lath of the edging board is 1.5-2 cm thick.

On top of the lath lay a layer of roofing felt, which is nailed to the base with nails with a wide bonnet. After that, the roof is stoned. For a frame house, it is preferable to choose a light roofing material, for example, ondulin or metal roofing. https://www.youtube.com/watch?v=gm9xv9JLozQ

On top of the lath lay a layer of roofing felt, which is nailed to the base with nails with a wide bonnet. After that, the roof is stoned. For a frame house, it is preferable to choose a light roofing material, for example, ondulin or metal roofing. https://www.youtube.com/watch?v=gm9xv9JLozQ

Warming and external finishing works

For finishing the frame house from the outside you can use a lot of materials: lining, siding, imitation of natural timber, etc. Before you do the finishing work, you need to make a crate under the finishing material. For the battens use wooden bars. Oblashku do, observing the step of 60 cm. As a material for the battens can use a metal profile. Wooden construction must be treated with an antiseptic. After this, the selected material is trimmed. As mentioned above, the frame house must be thoroughly insulated. Outside, the house is insulated with mineral wool, before finishing the walls.  Over the wool nails sheets of foam. Inside, the walls are insulated with mineral wool, which is subsequently closed with sheets of plasterboard. All the cracks are blown out with mounting foam.

Over the wool nails sheets of foam. Inside, the walls are insulated with mineral wool, which is subsequently closed with sheets of plasterboard. All the cracks are blown out with mounting foam.  In the frame house you need to insulate everything: roof, walls, ceiling. Between the layer of insulation and the base is laid vapor barrier. https://www.youtube.com/watch?v=T1DIzF-blu0 At the last stage of the work, all the remaining communications are carried out, finishing works are performed. The choice of finishes depends on the preferences of the builder, there are no restrictions.

In the frame house you need to insulate everything: roof, walls, ceiling. Between the layer of insulation and the base is laid vapor barrier. https://www.youtube.com/watch?v=T1DIzF-blu0 At the last stage of the work, all the remaining communications are carried out, finishing works are performed. The choice of finishes depends on the preferences of the builder, there are no restrictions.

More information on the process of building frame houses can be found by viewing the following materials: https://www.youtube.com/watch?v=64rWdpAx9NM https://www.youtube.com/watch?v=Ew4RCVCNCcA

More information on the process of building frame houses can be found by viewing the following materials: https://www.youtube.com/watch?v=64rWdpAx9NM https://www.youtube.com/watch?v=Ew4RCVCNCcA