Staircase structures, assembled independently, are considered by experts to be the highest class of skill. Straight rows of balusters and horizontal railings ensure the design reliability. Existing ways of fastening give way to more practical screed screeds, especially, there is a detailed instruction for installation and fastening. So why not try to install the balusters and attach the handrail?

Content

What are balusters, why do they need fixing?

Balusters are an element of any staircase and represent an intermediate element of the enclosure. The functions of balusters in the construction are considered to be a support for handrails or handrails, provision of movement and a completed decorative component of the staircase.

Obligatory rules of installation and fastening of balusters for stairs are the conditions:

• support bracket in 2 points (handrail / base of the structure)

• the distance in the light between adjacent elements is not less than 150 mm

• The recommended safe height is 900 mm.

Balusters are distinguished according to the geometric shape of the section (rectangular, flat, round and curly) and the material of manufacture (wood, metal, granite). It is noticed that the material of the balusters is selected for the material of the entire staircase, regardless the baluster is flat or curly.

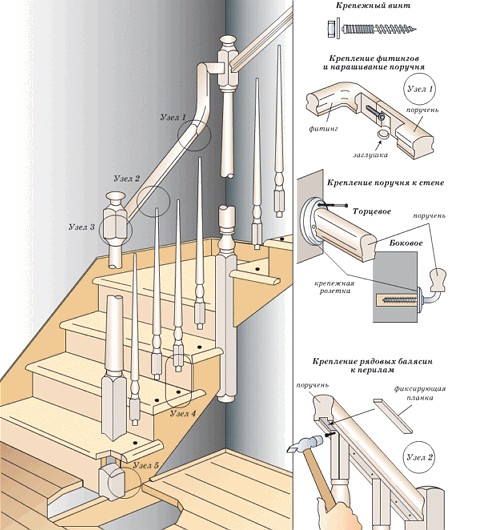

Methods of fixing to the base and handrails

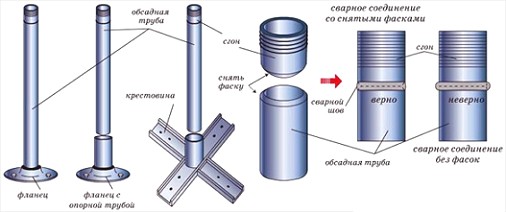

Fastening and installation of balusters are carried out in two ways - welded for metal structures and screwing by fixing the fastening unit to the screw (bolt).

Mandatory links of the attachment point are: a mortgage - a support rack-screw. For fastening metal balusters, a casing and a flange for support are additionally introduced.

The method of fastening the wooden baluster is more complicated and laborious.

Distinguish the technology of installation of balusters and its attachment to the landing of the staircase (to the floor) and to the stairs.

Fastening balusters on horizontal handrails

The final stage of the installation of the balusters is the upper fastening of the sub-pilot bar and handrail.

cross-section of handrails, rake and underbelly

The cross-section of the handrail with a height of up to 5.5 cm and a width of 6.5 to 7.5 cm can be straight, curved or stepped. Through the entire length of the handrail, a groove with a depth of up to 1.2 cm is available or removed.

With the use of rails, the fastening of balusters becomes simplified. It is advisable to install a sub-lamellae to fix the railing on the string or when the size of the balusters section is exceeded.

It is important to remember that the wooden railings at the fastening will require the creation of a technological hole for the fasteners to be installed.

The existing methods of fastening balusters with a pin, a square or cylindrical spike, a bracket are practically no longer used.

To install the railing on balusters "grandfather's method" can be, drawing information from the video.

How can I fix balusters on horizontal rails

To fix balusters on horizontal rails is possible and recommended using screw Screeds Zipbolt.

screw Screeds

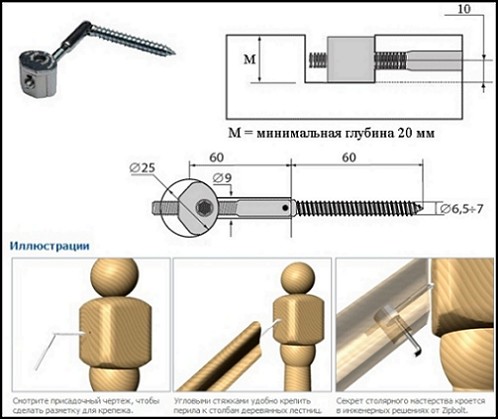

To fix the balusters on the rails I use screw ties, which are a hidden type of joining parts from a tree directly or at an angle of 90 to 180 °. Distinguish the screeds straight and angled, depending on the purpose, providing a single-level fastening of the handrail and fastening to the corner units.

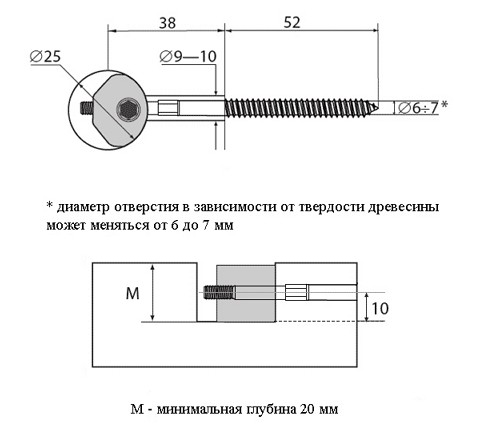

Screws are a screw connection with a removable gear. One part of the joint - the screw joint is installed in the place of attachment (in the baluster), the second part in the railing. The installed reducer on the counterpart of the screed ensures the fixation is stationary.

Screws on screws do not spoil the appearance of the stairs through holes and plugs.

One-level fastening

One-level fastening of balusters on the railing is used for established or existing pillars of wooden stairs, when balusters are located on one level and there are no corner units.

Self-manual fastening is carried out without additional milling of the technological hole.

In the set of single-level fastening balusters wood, screed screw straight:

• a removable steel gearbox with a minimum depth of 20 mm, a Ø 25 mm hole and a length of 96 mm

• the lock part under the stud

• adjustable stud Ø 8 mm, length 49 mm, external Ø screw thread 8.3 mm, screw length up to the bend axis 52 mm.

Detailed instructions for single-layer fastening of balusters to the rail

Step 1. We mark the top part of the ordinary baluster and the lower railing for the entry point under the screw of the reducer.

Step 2. We prepare a groove for the location of the reducer head

Step 3. We screw the screw part of the coupler to the planned point of the upper balusters.

Step 4. Screw the mating part into the railing.

Step 5. We pull the rail to the post.

Step 6. On the baluster, we fix the key part and fix it with screws.

Step 7. We fix the hairpin in the lock part.

Step 8. The screw with a 7 mm spanner is screwed.

Step 9. With a 5 mm hexagon socket wrench, tighten the reducer head.

The angular fixing of the balusters and railings is considered more difficult, for the conjugation of which it will be necessary to create a technological hole.

Corner fixing of balusters

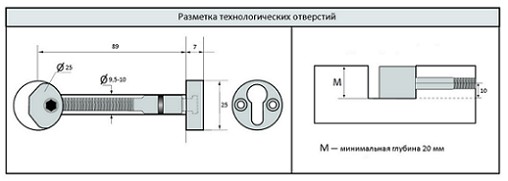

For corner fixing balusters to the rail use a corner screw screed, which includes:

• Removable steel reducer with a depth of 20 mm, diameter of the hole for landing 25 mm and the length of the body of the reduction gear 127 mm.

• Locking part with self-tapping screw for fixation.

• adjustable stud Ø 8 mm with external Ø screw thread 8.3 mm and thread length 61 mm to the axis of the bend.

To create a technological hole for landing parts of the screed you will need: a drill bit Ø 25 mm, a drill Ø 10х100 mm and Ø 2х40 mm.

Detailed instructions for corner fixing balusters to the rail

Step 1. In the railing we mark out and drill a technological hole at the minimum depth of the gearbox mounting taking into account the distance from the edge of the ordinary baluster to the drilling center (9.5 mm).

Step 2. We cut the end of the railing at the angle of mating with the baluster.

Step 3. We place the screw part of the reducer in the prepared hole.

Step 4. We twist the spire and mating parts into the planned points of the balusters and on the rails.

Step 5. We install the reducer head in the groove.

Step 6. We fix the reducer with a hexagonal wrench.

How to fix balusters to the railing using a Zipbolt screed, shown in the video.