On the pros and cons of metal staircases in private houses can be argued for a long time - does not creak like a wooden structure, durable and does not require complex maintenance. But it's worth starting to make or install a ladder made of metal, you immediately understand the minus of the laboriousness of the process and the arising gravity in the hands. To facilitate the complexity of activities help detailed instructions and useful advice.

Content

!}Staircase to the second floor in the villa

One of the first inventions of mankind and a kind of engine of multi-storey construction, consider a ladder. From the first stone steps and rough-built wooden staircases, the structures acquired new shapes through the use of strong materials.

Durability and a sturdy metal ladder can not be overestimated, especially since for manufacturing in metal structures high-quality material is used. There are many types and drawings of metal staircases, internal, leading to the second floor and external.

Let us suggest that the design of the staircase in a private house determines its design - with straight marches, screwed and with a platform or a race.

The manufacture of the metal ladder begins with the design and selection of the design with a reasonable calculation and drawing by sweeping the ladder on the wall.

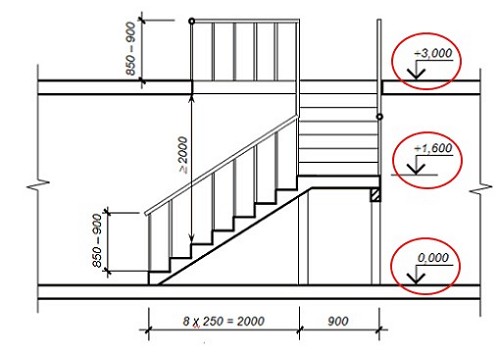

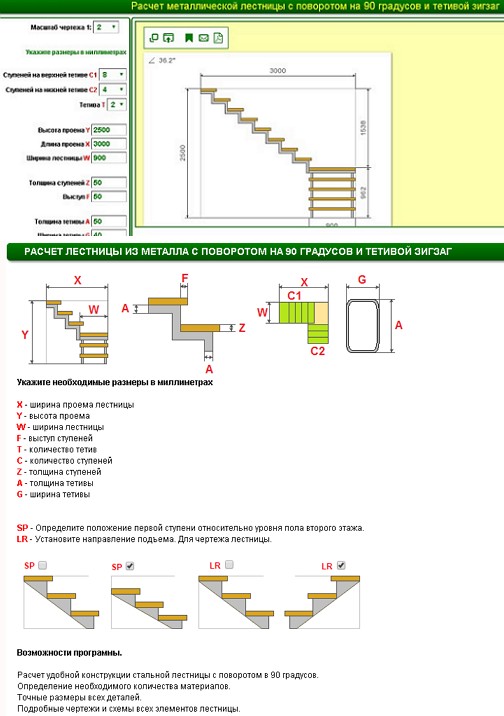

Calculation of metal stairs

Calculation of metal stairs is identical to the calculation of stairs from another material.

The initial data for calculating the metal ladder to the second floor of a private house are:

- height and width of the installation opening

- relative staging and gradient

- the parameters of the steps with allowance for the projection and their number

- parameters for setting bowstrings or strings.

As a result of the calculation carried out on the calculator on line, the following results will be obtained:

- staircase comfort characteristics

- the dimensions of the steps and their total area

- the number of metal profiles for the installation.

Based on the calculation results, a conclusion is made on the choice of the material of the attachment points (profile angles, channel bars and pipes).

The next step is to choose the configuration of the marches:

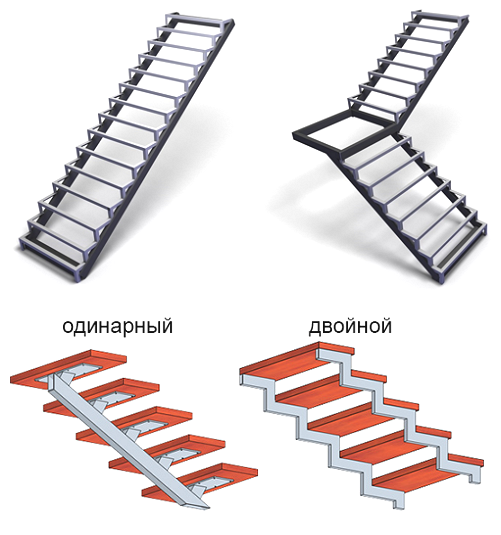

- direct one-stage, one-dimensional steps of which are arranged in series along a straight line, the support is a kosour

- screwed with axial base of metal frame of ladder

- spotlights with a turning part of the march with a platform or steps.

For any kind of metal ladder, the manufacture can be made by hand. Therefore, it will not hurt to learn the principles of fastening the frame elements.

Methods of fastening frames, steps and handrails

There are several possible ways to install the stairs to the second floor in a private house:

- a metal frame consisting of a supporting part and a framework for steps (the center of steps is not filled)

- screw screed for solid metal or wooden steps

- an obsolete way of using a frame made of wood with fastening steps with screws, dowels and threaded studs

- fastening of handrails Screw Screeds

Manufacturing of metal stairs

commercially manufactured frame

The best variant of a metal staircase to the second floor can be considered a finished frame, consisting of typical parts and elements of typical configurations of stairs: L-shaped, U-shaped, screw, with a straight march and a platform.

The finished frame of any configuration has a negligible weight, simple calculation and ease of installation with standard fasteners. Such a metal frame has a supporting base of I-beams or channels, with distributed kerchiefs pair-wise reinforced in the march.

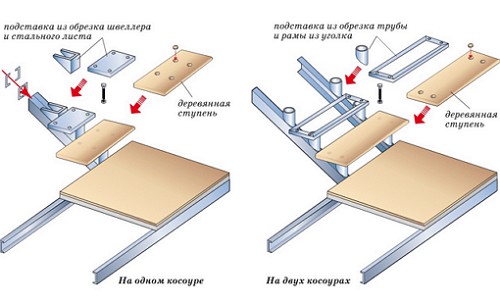

Mounting steps of wood is carried out for the stairs on one kosoura on a stand from the channel and steel plate. For the staircase on the two oblique legs, the steps are mounted on a pedestal of scrap pipes and a frame from the corner.

install a ready ladder on two strings or string

Detailed instructions (basic technology)

Step 1. Layout of the floor area for installation of strings or stringers.

Step 2. Assembling the finished site of rectangular metal.

Step 3. Mounting of the fastening unit in the upper part of the opening.

Step 4. Placement of the ready-made Kosowra (bowstring) in the opening and fixing it in the upper part on the supporting pillar fixed to the inter-floor covering.

Step 5. Fastening the bottom of the strings to the support platform.

Step 6. Placement of the second Kosoura in the opening and its fastening in the upper and lower parts.

Step 7. Securing with each other installed skosurov by welding or bolted connection.

Step 8. Welding or installation of support angles and welding of steps.

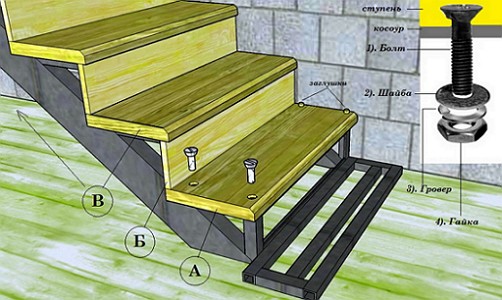

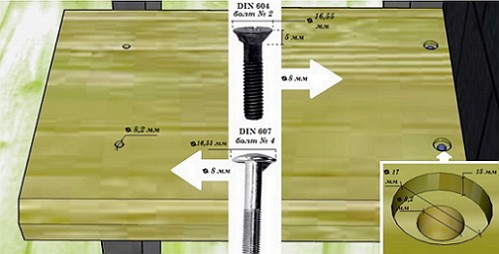

Step 9. Drilling of mounting holes for steps and platforms.

Step 10. Mounting and fastening of steps, platforms and handrails using screw ties.

Step 11. Grinding of burrs, priming and painting of oblique, string and steps.

How to build a wireframe metal ladder, shown in the video.

the staircase to the second floor on the Kosoura and the staggered steps

detailed instructions

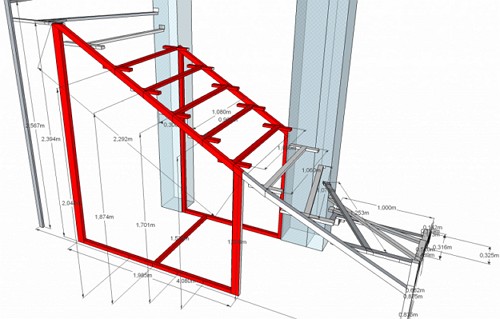

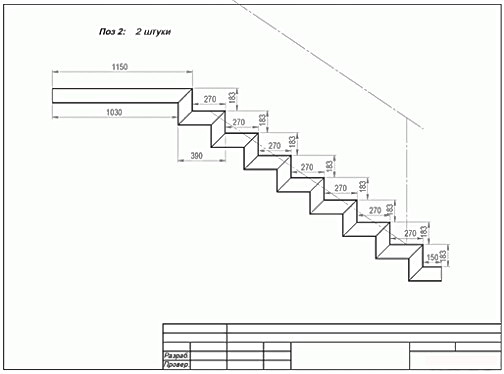

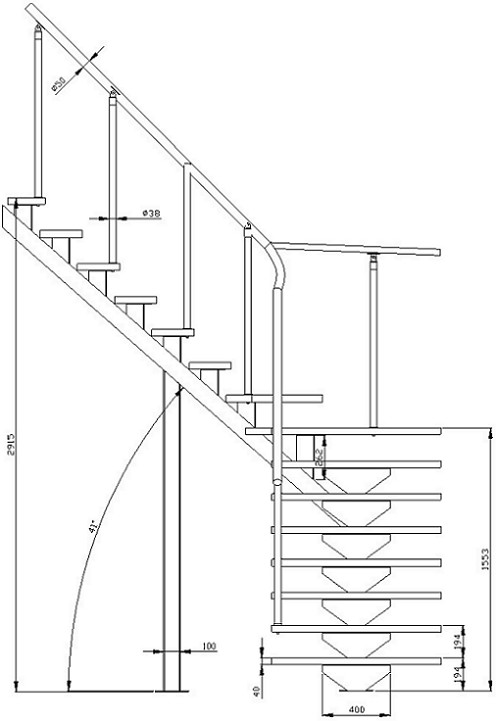

Own production of a metal ladder in a private house on a Kosower with a turntable of 90 ° begins with the preparation of the material according to the drawing and preliminary calculation.

For example, for a metal ladder with an opening length of 3315 mm, a height of 2,915 mm, a width of 1,000 mm march, and a number of steps 14, it will be necessary to make a frame of 100 × 100 mm pipe with installation on supporting pipes.

Stages of stair manufacturing technology

Manufacture of kosoura

Step 1. Preparation and cutting of blanks according to the working drawing.

Step 2. Manufacturing of stages fastening units.

Step 3. Placement and fixing of the upper part of the kosoura in the opening.

Step 4. Fastening the bottom of the strider to the platform.

Step 5. Marking Kosovra in altitude.

Step 6. Installation of support pillars and fillets.

Step 7. Drilling of mounting holes for the installation of poles, steps and planks of the site.

Step 8. Welding of support corners.

Welding of stages

Step 9. Placement of ready-made units for fixing the steps on the kosoura along the heights.

Step 10. We make the marking of the square pipe for the edges of the Kosowra.

Step 11. Welding of fastening points and steps.

Step 12. Mounting and fastening steps to the filly.

Step 13. Manual grinding of burrs, priming and painting steps and kosoura.

Step 14. Installation of metal balusters and handrails.

How to weld a skeleton of a metal ladder on a Kosower, shown in the video.