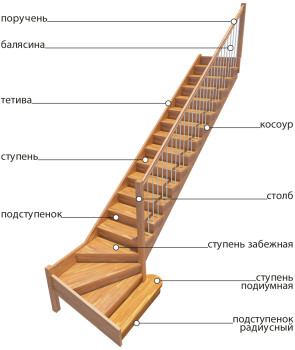

The inter-storey staircase is one of the most complex and labor-intensive modules of a residential building. In respectable construction firms, a separate staff is being recruited to develop staircase projects, which only deal with this issue.

Since recently the prices for design and construction work are constantly creeping up, many developers prefer to build their homes on their own, starting with the project, How to make a house layout and avoid errors will prompt a specialized site, because the cost of land in places where there are even the beginnings of civilization is such that it is more advisable to build a two-story house, or at least a house with a residential attic, in which, whatever one may, have to install at least one interstorey staircase . And in the usual one-story house there is a basement or an attic, where you need to periodically go down and go up. In short, practically in any house without a good ladder is indispensable, and in this publication we will outline in general terms how to decide on the type of staircase for your house, to make a ladder of wood, metal or concrete with your own hands, and give some video instructions for more detailed acquaintance with the question.

Content

Calculation of stair flights

From the correct design calculation directly depends on its strength, durability, comfort and safety in operation. Before starting the calculations, it is necessary to make measurements of the room to determine the dimensions of the room. After that we transfer the dimensions to paper. Then we perform the following actions: we measure the height from the floor of the first floor to the floor of the second floor, taking into account the thickness of the floor. Next, measure the dimensions of the opening. These parameters, in general, are sufficient for the calculation of stair flights.

Consider the calculation of the ladder march on the example of a single-ladder ladder. The calculations should answer the following questions:

- What will be the depth of the tread?

- What will be the height of the step?

- What will be the angle of construction?

- What will be the dimensions of the product?

- What will be the size of the march?

To calculate the dimensions of the future design, you must apply the contours of the ladder to the room plan. The angle of inclination of the march should be no more than 30-45 degrees. This indicator is extremely important for the convenience and safety of the structure. If the location of the product is known in the plan, it is easy to calculate the angle of inclination graphically.

To make the staircase comfortable and comfortable, the following formula is used in the design: 2a + b = 64 cm, where "a" is the step height, "b" is the width of the tread. The step height should not be less than 12 centimeters and more than 17. In order to calculate the number of steps, it is necessary to divide the height of the room by the height of one step.

The length of the ladder march can be calculated using the Pythagorean theorem. To do this, the projection of the length of the ladder is raised to the square of the height of the floor. The projection and height of the room will act as the legs. From the obtained number, it is necessary to extract the square root. The resulting number will be the length of the ladder march.

Important: the distance between the top edge of the tread and the ceiling must be at least 2 meters, and when lifting this distance should be the same. If you can not withstand the distance, you need to increase the opening in the overlap.

For more information on calculation of stair flights and the manufacture of stairs, please see the following video:

Where to start, the choice of material for stairs

Behind the apparent simplicity of the interstore ladder lies a very solid foundation, to be seen and evaluated only by a specialist. After all, if you regularly use a seemingly reliable but "slightly wrong" designed ladder, you can get some health problems, to put it mildly.

It would seem that the technology of mounting staircases is completely painted and chewed to the smallest detail in the construction manuals. But the whole point is that they are designed mainly for staircases in apartment buildings of typical development, and absolutely all individual features and requirements can not be taken into account by any norms and SNiPs.

In private country houses, stairs with their own hands are most often built of wood, reinforced concrete, metal, and also combined. Stairs of these materials withstand the SNiP load of 150 kilograms.

wooden staircase

One of the most simple and affordable options for those wishing to do it is to edit the staircase of wood. But with the price is not all simple. The fact is that products made of coniferous woods that have a straight-layer structure, will soon crack up and crack, begin to stagger and creak.

And although the staircase is tied to the construction of the building to a small extent, and it can be repaired or, at worst, done anew, it's a waste of time and money. And business wood in the foreseeable future will not fall in price. For stairs, small-leaf hardwoods are more suitable: oak, beech, walnut, ash, maple, etc. However, the cutting of these species is strictly limited, in the implementation of the idea, only well-dried and processed wood.

Therefore, hardwood sawnwood is expensive, and long-length materials are very expensive. Wood of hardwoods is very fond of all sorts of pests, so buying hardwood sawnwood, ask if they have been treated properly.

However, staircases from inexpensive coniferous species are appropriate in several cases:

- Attic stairs - retractable or folding. Dry microclimate in the attic contributes to a long life of the product - no less than the rafters.

- A staircase to the one-and-a-half floor or seasonal attic.

- Stairs to mezzanine or sleeping loft. In this case, the product can be properly impregnated with a water-polymer emulsion, varnished or simply painted, which will ensure reliable protection of the wood, and it will not be very expensive to replace such a ladder.

Absolutely all wooden products are created according to the common technology with the same tools. However, in our case, we are dealing with a staircase - a piece of furniture, attached to the building itself. The staircase is fixed to the finished finishing floor in the fully finished room. Accordingly, the floor and walls may not be perfectly even, and the corners are inaccurate. Therefore, before you start the installation of the ladder, you need to know some of the nuances:

- The form for the bearing beam (bowstring) is printed on a printer in A2-A3 format on a scale of 1.:1.

- The finished pattern of the supporting beam is temporarily fastened to the walls, taking into account all irregularities, bends and kinks. The pattern of the supporting beam is precisely verified and corrected accurately in size to zero clearance - at the top, bottom and along the entire wall.

- Reiki, imitating staircases, which are carefully leveled horizontally, expose the template of the second bearing beam. It will be much more convenient if the template is pasted onto a strip of packing cardboard before it.

- When the patterns are adjusted, the horizontal size of the steps and the platform is determined and corrected. The height of all steps must be exactly the same.

- The exact height of the ladder supports is determined.

- Based on the size of the upper opening, determine the exact height of the rails and pillars-balusters. All parts of the ladder are cut to size and assembled. After that, only the finishing is left.

metal staircase

Most of the ladder is made not from the same metal, but in combination with other materials. For example, the frame can be metal, and the steps - wooden or concrete, with any decorative finish. Combined ladder of metal and wood will cost about 50% more expensive than wood, and its erection requires much more time and effort. But the metal frame will serve as much as the house itself, and the finish can easily be replaced or repaired, without doing any serious damage in the living room. A ladder made of metal can be installed in a fully finished building, however, after that you will need to make a small renovation of the premises.

In general, the technology of mounting the metal ladder is as follows:

- First, prepare two metal beams from the channel 60-100 mm for the site. Beams must go into the supporting wall to a depth of at least 10 centimeters, and if the wall is made of bricks or wood, then by 12-15 centimeters.

- It is not advisable to mount a ladder into the wall from aerated concrete or a foam block, but if there is such a need, then the beam must pass through the entire wall right through. This must be taken into account when determining the length of the beams.

- Further in the walls break through the niches for the beams. In the walls of the foam block and aerated concrete penetrate through holes.

- First, in the finished holes, start the far, and then the near beam. Further, the beams are exposed to the level across and along, and the entire site is checked diagonally.

- To set the beam exactly on the level, it must be wedged in a niche with pieces of sheet metal from all sides. The tufted beam should sit in the nest so tightly that it can not be moved horizontally by the croaker.

- If the beams are installed in a stone wall, then after they are leveled, they must be cemented.

- In a wooden wall, the beams are closed with a thick mass of sawdust and liquid nails.

- In the place where the heels of the beams will be, remove the flooring and the screed before overlapping.

- After a few weeks, you need to check the pad again horizontally.

- Next, slant beams are prepared in size, welded to the site, and the heels of the beams are fastened to the ceiling by means of anchor bolts.

- After that, the skeletons of the steps are cooked from the metal corner. Vertical shelves of the frame of the steps for concrete are oriented in the direction upwards, and under the wooden steps - down.

- Next, the steps are sheathed or poured with concrete, and the finishing of the staircase is made.

I would like to note that all-metal welded stationary staircases are used very rarely in everyday life, as they do not look very aesthetic. The metal staircase can be decorated and beautified by gluing a wooden or extruded polystyrene foam on the step. After you are ready to guard the staircase (it is advisable to make them from stainless steel), and the staircase is painted, it is desirable to paste the lining of corrugated rubber, or at least of linoleum or carpet, onto the steps of the steps.

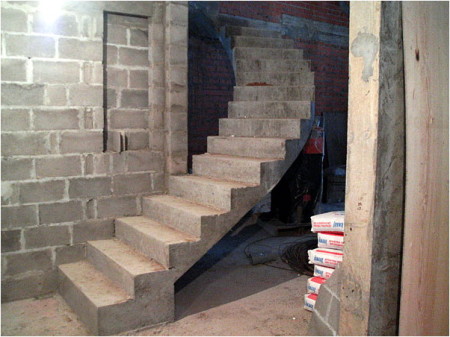

concrete staircase

Reinforced concrete ladders are most often used in typical construction, as there are practically no alternatives to them. As for private construction, in this case, build concrete staircases of two types: combined with metal (not reinforced concrete) and completely monolithic.

Combined stairs make, pouring a concrete metal frame, the same as for a metal-ladder ladder, only reinforced with rods of reinforcement. The staircase. Which is subjected to less stress, is eliminated in any other way.

Combined concrete stairs can be made independently. True, the task is quite laborious, but the concrete construction will last a very long time, and at the same time it will never creak and wobble. For the installation of staircases and platforms, a special mortar of concrete is required, which has increased resistance.

Mix the mortar only in a concrete mixer.

The composition and method of preparing concrete for the ladder is as follows:

- Cement brand 500 - 1 part.

- Fine river sand - 2 parts.

- Marble chips are 2 parts.

- Water - 0.7 parts.

- The plasticizer is 0.01 part.

To prepare the mortar, start the empty concrete mixer, load the marble chips, sand and cement first, stir about one minute, then add water. After that, mix to the desired consistency, add plasticizer and wait another minute. The finished solution must be used within 20 minutes.

The construction of the combined ladder has several important features:

- The channel for the platform should be from 80 mm, the corner for the frames of the steps - from 40 mm.

- Armature - 6-8 mm for the steps, and 8-10 mm for the sites.

The frame of the step - several longitudinal bars of the reinforcement and up to 5 transverse ones. The reinforcement mesh for the site must have a mesh of no more than 300 mm.