The foundation tape on bored piles is very popular among private developers. It was widely spread, first of all, because of its small cost compared to the usual ribbon foundation. According to SNIP, the strip foundation must be buried below the freezing point in order to avoid deformation of the base if the house is built on a heaving ground. The depth of freezing in the middle zone of our country averages 1.5 meters. Therefore, the base of the strip foundation should be buried at 1.7 - 1.8 meters. And although such a foundation is very reliable, not every developer can afford such expenses. Using piles allows you to save considerably on materials without losing the strength of the base.

Below we will describe what this design is, consider its pros and cons, as well as manufacturing technology.

Content

Pile-and-tape foundation: for and against

Before considering all the advantages and disadvantages of the pile-and-tape foundation, it should be noted that it can not be considered as a universal option - only specialists can give an unambiguous answer for each specific case.

Among the merits of this design can be identified:

• Possibility of use on weak- and medium-patchy soils (clay, loam, sandy loam, sand dust).

• Relatively low consumption of material compared with other types of foundations for undergrowth.

• Relative simplicity of installation, the ability to make a foundation with your own hands, without attracting heavy construction equipment.

Disadvantages:

• The need for complex calculations for the joint work of piles and ribbons, the diameter of the piles, the dimensions of the tape-grillage for each specific case. Calculations should be carried out only by a specialist.

• Pile foundation is not recommended for buildings made of heavy materials.

• The impossibility of a semi-basement or basement room.

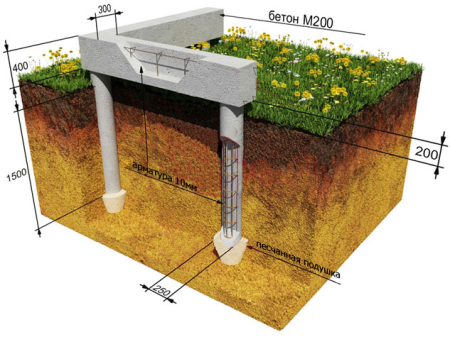

How does the device of the ribbon foundation look like on piles

To put it simply, a shallow or unstripped ribbon-grill stands on piles, the base of which is located below the freezing point and rests against solid layers of soil. Thanks to the piles, it is possible to significantly strengthen the entire structure, and make it as durable as possible with a small consumption of material, which is especially important during seasonal priming of soils. And the piles (bored) and the basement are mandatory reinforced with reinforcement. Recently, screw piles are often used, which represent something like a giant self-tapping screw, screwed into the ground with the help of special equipment.

Belt foundation on screw piles is erected much faster, since screw piles do not require reinforcement, they are mounted in a short time, but also cost several orders of magnitude more.

The technology of manufacturing bored piles is discussed below.

Where it is expedient to use the pile-and-tape foundation

This construction is most often used in low-rise construction for the construction of residential houses, cottages and other types of buildings, which do not provide a basement. Theoretically, such a foundation can be used on all types of soils, except rocky, but more often the belt-pile foundation is built on medium-pit soils and in areas with complex terrain.

Materials for the construction of pile-and-tape foundation

• Sand or granite screenings.

• Gravel or small gravel.

• Mortar of concrete.

• Reinforcement cross-section 10-12 mm.

• Waterproofing and heat-insulating material.

• Primer and antiseptic solution.

• Pipe is asbestos-cement or metal.

• Materials for the manufacture of formwork.

Instruments:

• The bayonet is bayonet and shovel.

• Hand drill for soil.

• Roulette, building level.

• Concrete mixer.

• Knitting wire and hook for binding the reinforcement.

Once all the necessary materials and tools have been prepared, you can proceed directly to the construction of the foundation.

Bored tape foundation, construction by own hands

The construction on the piles of a tape (foundation) foundation is carried out in the following sequence:

• Preparation and marking of the plot under the foundation.

• Earthworks.

• Installation or pouring of piles, depending on their type.

• Reinforcement of grillage.

• Installation of formwork.

• Pouring concrete piles and tapes.

• Final work, dismantling of the formwork.

preparation and marking of the site

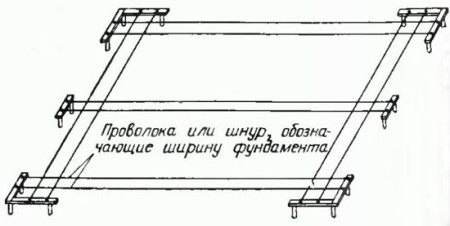

the construction site under the foundation is completely cleaned of debris and the upper layer of the soil is removed. Marking is performed in a standard way, as well as under the usual ribbon foundation - with the help of pegs and cord. The only difference is that you need to make marks in the places where the piles will be mounted.

In the corners of the future tape drive pegs or pieces of reinforcement. Next, on the surface of the ground, mark the inner and outer boundary of the foundation, pull the cord.

After the contour of the foundation is ready, the places for installing the piles are marked.

excavation

All excavation work consists in digging a trench under grillage and drilling small holes for piles. Trenches under the belt are usually dig shallow, but on heavily soils it is recommended to dig a trench for a belt about 80 cm deep. Fill the bottom of the finished trench with a layer of about half a meter. The concrete tape falls on a sand cushion, which compensates to some extent for the priming of the soil.

Before the backfilling, trenches drill wells under piles.

A manual drill is usually used. The depth of the wells should exceed the depth of freezing of the soil, which on average is 1.5 m. When drilling wells, it is necessary to take into account that sand should be poured onto the bottom. The thickness of the layer should be at least 30 cm. Thus, the depth of the well should be not less than 1.8 meters.

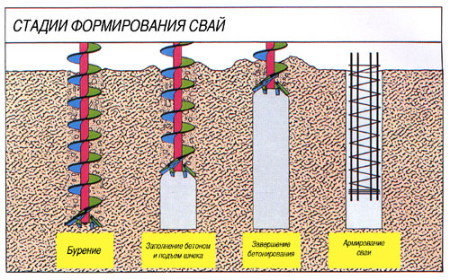

installation of piles

If screw piles are used, wells are not needed for them - they are simply screwed into the ground. When installing bored piles, it is necessary to provide high-quality waterproofing of concrete. For this, asbestos-cement or metal pipes can be used.

Sometimes as a waterproofing agent, a ruberoid twisted into a tube in several layers is used. Then one or several reinforcement rods (depending on the borehole diameter) with a section of 10-12 mm are lowered into the well. The ends of the armature should protrude above the well for 20-30 cm for subsequent ligament to the grillage.

preparation of grillage

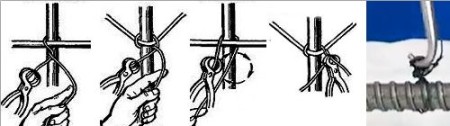

For reinforcement of the foundation tape, reinforcement with a cross section of 10-12 is suitable. The bars of the armature are tied into the frame by means of a special knitting wire and a hook. For a bundle, you can also use ordinary pliers, since the hook for knitting the armature is a very specific tool, and it is difficult to find it on sale.

The reinforcement frame is knit with a pitch of 200 mm. The finished frame is laid in a trench on a sand cushion, preliminary having put under it wooden бруски that concrete has hidden the bottom rods. Next, connect the frame and reinforcement from the wells for the piles.

formwork

Formwork can be made from boards, knocked them into shields, or from sheets of dense plywood. When assembling the shields, the heads of self-tapping screws or nails should be inside, and the bars with which the shields are fastened - from the outside, so that there are no problems with dismantling. When the formwork is ready, it is installed along the edges of the trench along the entire perimeter. On the outside, the formwork is securely unfastened by struts, spacers are installed on the inside so that the boards do not fold during the pouring process. If the foundation is high, then the formwork boards are fastened together by clamps, and wooden stakes are driven into the ground from the outside.

pouring concrete

It is best, if there is such an opportunity, to order the right amount of concrete in the plant, since the pouring must be done at a time. However, in practice, often poured concrete into several layers, the concrete is made in place using a concrete mixer. For the preparation of a concrete mixture, cement, gravel and sand (granite screenings) are used. The proportions are 3/1/5, respectively. The solution is diluted with water to medium consistency - it should not be too thick to fill freely all the cracks and voids, and too liquid so that the cement "milk" does not flow out of the cracks of the formwork.

First of all, piles are poured, then a foundation grill. In the process of pouring concrete should be well tamped, so as not to create voids. Professional builders use a special vibrator for concrete, in conditions of private construction it is possible to use an ordinary wooden pole and knock the formwork well with a rubber mallet.

When concrete is poured in the winter, special mortars must be added to the mixture, protecting the concrete from freezing. At a temperature below -20 degrees, heaters are used, a special wire is placed inside the reinforcing mesh, which, when heated, does not allow the concrete to freeze. In the warm season, after the completion of pouring, the surface is covered with a film, and for a month watered to prevent the concrete from cracking.

After pouring, after about a week the foundation collects half the strength. Full strength is achieved after 20-30 days from the moment of filling. After this, you can start building the walls of the building. For the waterproofing of the finished foundation, ruberoid and various bituminous or polymeric mastics are used. To reduce heat loss and partially compensate for soil punching, the foundation is insulated with polystyrene plates, which holds heat very well and has sufficient elasticity.

Plates are attached to the outside of the foundation, with special adhesives used. After the glue has dried, polystyrene is additionally fixed with plastic dowels.

In conclusion, we note that the ribbon foundation on piles with their own hands can be done without attracting heavy construction equipment, the main thing is to entrust all calculations to professionals and clearly observe all their recommendations.