Pile screw foundations are no longer a curiosity in individual construction. The foundation, erected on easily screwed piles, is cheaper than others. The reliability of the fence installation on the pile foundation is indicated by the available installation technology, and if the self fence from corrugated board price which is quite acceptable - we get a modern, reliable, light and beautiful fencing of a country house. And what is most attractive - there is no need for a tedious expectation of "shrinkage" and "dirt" of the soil. The fence can be started confidently right after screwing in the piles. How to properly install the fence yourself?

Content

Advantages of screw piles for installation

The optimal option for a successful combination of "price-quality" can be considered a fence on screw piles, which is the protection of your own home or home area. The installed fence for the installed installation technology can be erected on "problem" soils, including loam, marshy terrain and heterogeneous terrain with a significant difference in altitude.

It is preferable to install the fence on screw piles in such cases:

• when the pile screw can serve directly as a fence post

• for reinforcing the base of metal gates or gates

• with the reinforcement of the base of the fence post from the brick and the wooden fence.

By the way, labor costs for erecting a pile-screw base under the fence are minimal. The foundation can be screwed in and the fence installed in a few days.

Secrets of the screw pile mounting technology

Specific design of its screw assumes strict adherence to the installation technology, which consists in the following stages:

• Test screwing of a separate pile

• screwing the required number of piles

• piping the profile

• Strapping the channel

• protection against corrosion at the boundary between two air-to-air environments.

The technology of installing piles can be considered general, regardless of what type of fence it is supposed to install later: lattice, from sheets of corrugated board or wooden.

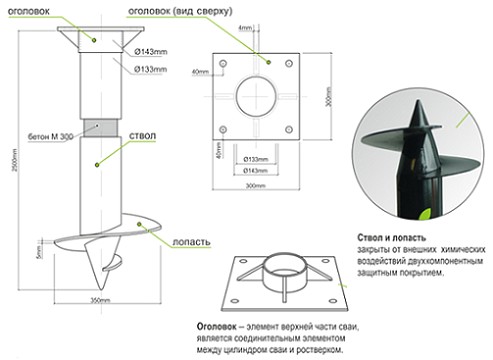

Piles of screw for a fence can be conditionally represented in the form of a large screw with a cast tip, which by means of mechanical action is screwed into the ground.

Naturally, such a "screw" should have an impressive diameter and thickness of the blade pile screw, as well as the tip of the cutting material. The pile screw must subsequently provide the maximum load carrying capacity. How to properly turn the pile screw and install a fence?

How to install a fence on piles of screw ones yourself

preparatory calculations and works

Before the installation of piles, it is necessary to make some calculations, the result of which will provide accurate information on the required number of piles. It is recommended to use on line calculation, with which you can find out the cost of the fence on screw piles.

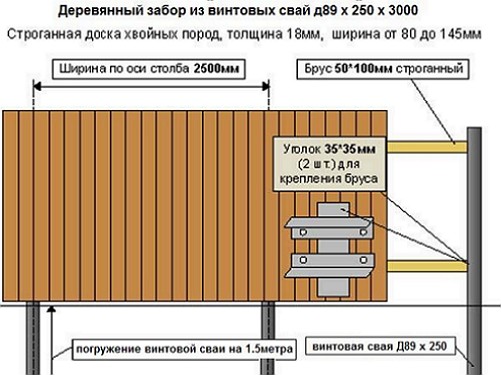

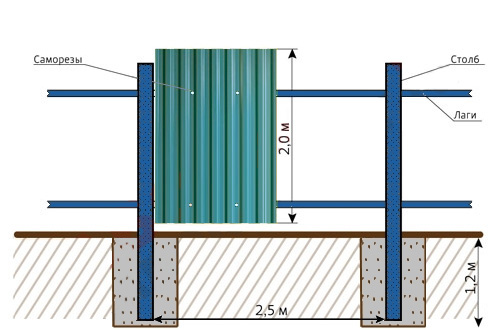

Therefore, design structures are the main supporting elements for brick or wooden fences on screw piles. It is recommended that the distance between neighboring piles be between 2.5 and 3 meters. The depth of installation of piles for fences is from 1.5 to 3 meters. The installation depth depends on the depth of soil freezing in the area, this must be remembered.

After preliminary calculation, the terrain (axes of loadable piles) is broken down for their subsequent installation and fixation with the use of orienting pegs.

test screwing of the pile

Before the construction and installation of the fence on piles, a single screw piercing test is performed, which will accurately show the depth limit, as well as the qualitative composition of the soil.

The process of test screwing of the pile will not differ in any way from the main technological process, except that the test pile should be taken back to the surface. Such an empirical measure of soil investigation makes it possible in the future to prevent the pushing of the support against the surface by the forces of frost expansion. Realizing the qualitative composition of soils, it is possible to start the basic process of installing screw piles safely.

screwing of screw piles

For the construction of light structures and fence posts, piles Ø 76 - 89 mm are used.

So, for example, the technical characteristics of pile screw Ø 76 are as follows:

• Barrel wall thickness - 3.5 mm

• thickness of pile blade - 4 mm

• blade diameter - 200 mm

• The maximum bearing capacity of the pile is 1500 kg

Screw piles of diameter 76 mm can be used when erecting a wooden and brick fence on screw piles.

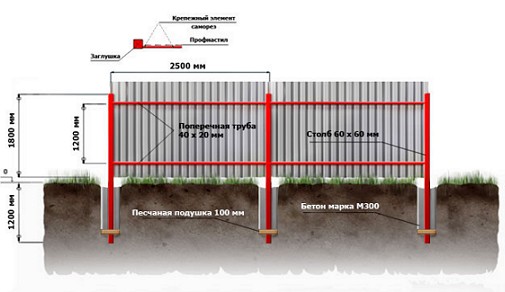

Piles of screw Ø 89 mm are capable of withstanding the load that will be created by the fences from the corrugated board.

Piles can be wrapped in the ground in a manual and mechanized way. With a mechanized method, the piles are wrapped using a mini excavator equipped with a swivel.

After installing the required number of piles, they are strapped using special fasteners.

tying of installed piles

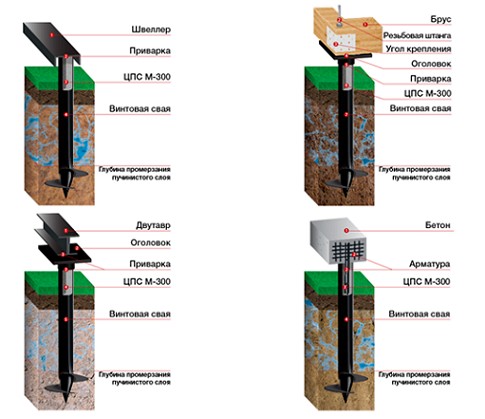

To create the integrity of the design, you must do the following:

• Concreting pile shafts with a mixture of concrete grade M300

• fasten piles with beams, channel bars, I-beams, first wreath, grillage or monolithic slab.

It is necessary to make the piping of the pile-screw foundation immediately after installation, excluding the piling of the markings by changing the location of the piles. The change in the position of the piles is caused by the accumulated residual stress provoking the position of the pile to its original trajectory. There are several types of strapping, but it is recommended to perform them after finishing the concreting and leveling works.

protection of corrosion piles

After tying the screw piles, the ground part is protected. To protect the ground, the piles are treated with anti-corrosion agents.

The final stage of the installation of the fence on piles of screw is the filling of interwire space. As a filler can be used: corrugated board or wooden sections.

How to install a fence on piles with your own hands

To install a pile fence of corrugated board or wood with your own hands, you will need to do the following:

• install screw piles in steps of 2.5-3.0 meters, according to a preliminary calculation

• to produce to the pillars of piles fastening of metal transverse logs (2-3 lugs)

• Carry out installation of corrugated board or wooden boards with fastening sheets to logs and posts.

On the universality and practicality of the design of the fence on screw piles it is enough to get acquainted with the positive feedback of those who have already installed the fence.

How to install screw piles and a fence is shown here.