In the process of modern construction works, a variety of waterproofing materials are used, including so-called penetrating waterproofing.

Waterproofing materials with a penetrating effect are produced by both foreign and domestic producers. What is penetrating waterproofing, for which building materials can it be used, what is the principle of the action of this type of waterproofing - we'll talk about this in this article.

Content

General information

For the first time the idea of using waterproofing materials of penetrating action appeared in the 50s of the last century in Denmark. The first industrial sample of penetrating waterproofing was produced by the Danish company Vandex - the same name was given to the product. Based on the development of Danish scientists, similar materials began to develop manufacturers of a number of countries: Canada (Xypex), waterproofing Penetron (USA), Spain (Drizoro). More recently, industrial production of penetrating waterproofing was established by domestic producers. The most popular and well-known products of the Russian manufacturer include: Hydrocit, Kalmatron, Coral, Lahta, Hydrotex, and penetrating waterproofing Crystallizol.

Penetrating waterproofing materials are highly reliable and effective, providing maximum protection against moisture penetration.

Feasibility of processing penetrating waterproofing of concrete surfaces

The effectiveness and expediency of the use of this material, we will consider several examples: waterproofing the foundations of buildings, semi-basements, cellars, and wells. These structures are made of concrete with a porous-capillary structure. Throughout the entire period of operation, these structures are constantly under the influence of aggressive moisture, subject to temperature changes, ground pressure, etc. All this has a destructive effect on the structures. So, inside the cellars there is constantly a deformation, high humidity, detachment and destruction of finishing materials.

Traditional roll materials in this case are completely inefficient, time consuming, and quickly deteriorate. With bitumen-containing lubricants, too, there are enough problems, although many owners use these waterproofing materials, adding to their efforts. So does the problem solve the use of penetrating waterproofing? The answer is unequivocal - yes, it solves, but on condition of an integrated approach and a properly selected waterproofing system.

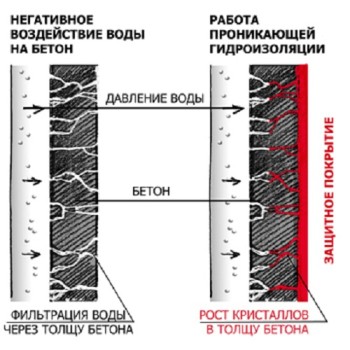

The mechanism of operation of penetrating waterproofing is based on the course of the chemical reaction between the active components of the material and the free lime contained in the concrete (calcium hydroxide).

So, for example, Penetron penetrates the waterproofing of the US production. As a result of the reaction within the concrete, hydroaluminates and calcium hydrosilicates are formed.

Being practically insoluble products, they substantially compact concrete, increase its strength and waterproofness.

Even if the penetrating waterproofing has been applied to the surface with a roller or brush, its components still penetrate deeply into the concrete.

Where penetrating compounds are used

Waterproofing penetrant type is almost indispensable for the treatment of roofs, bridges, treatment facilities, wells, cellars, pools, ports and piers. And this is only a small part of the list. This type of waterproofing is widely used for surface treatment inside and outside buildings.

Advantages of penetrating waterproofing

Advantages for this type of waterproofing materials is quite a lot. Its application provides reliable volumetric isolation, self-healing of the material, significantly increases the frost resistance and strength of concrete, as well as its reliability and durability. At the same time, the vapor permeability of the material remains, and the resistance to mineral oils, sea water, and the effects of other aggressive materials increases. The material has a very high penetrating power, reaching a dozen centimeters. The waterproofing of concrete penetrating is applied to wet surfaces, both from the inside and from the outside, even with a positive water pressure. Waterproofing begins to work immediately after application to the surface, gradually increasing its effect.

Surface preparation for treatment

Before applying waterproofing to the surface, it is necessary to carry out a number of works on its preparation. The bottom line is this: first you need to ensure the drainage of water - all the places of possible leaks can be blocked by hydraulic splints. To this end, you can use materials such as Waterplag, Penelag, Gidroteks. Started to collapse, loose concrete is removed and strobim.

The destroyed surfaces must be repaired with non-shrinkage compounds. If there is a need - to make a new screed, plaster and level the surface, on the concrete structures open the capillaries, remove the mold, fungi and moss, patch the cracks having a size of more than 0.3 mm.

In addition, it is necessary to carefully seal the places of entry of pipes and other communications with the help of a sealant.

These recommendations are of a general nature, they vary depending on the processing object. After all the preparatory work is completed, you can proceed to surface treatment with penetrating waterproofing according to the instructions given on the package. To apply the composition to the surface of the concrete, use a brush or roller.

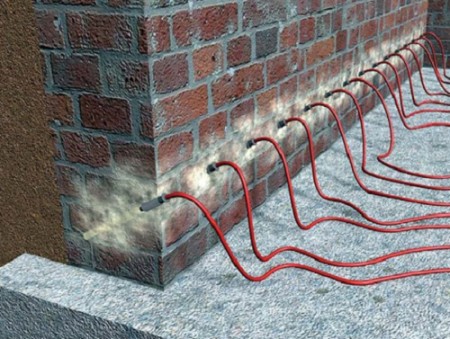

Use of penetrating waterproofing for brickwork

Until recently, this type of waterproofing was used only for the treatment of concrete surfaces. Today, waterproofing penetrating action is also used for brickwork. Processing is done in two ways:

Shutoff waterproofing. Using this method, the composition is injected under pressure into the brickwork. To do this, holes are drilled in a staggered manner, observing a pitch of about 250 mm and an angle of 30-40 degrees from the surface. After that, the waterproofing is pumped according to the instructions.

The second method is called a "plash shirt". The brick is partially cut down, the seams between the bricks are expanded, and they are sealed with suture compounds. After that, a layer of plaster is applied, containing penetrating additives, a penetrating waterproofing is applied to the plaster. It should be noted that the work on the waterproofing of brickwork requires the use of special equipment, and they are performed only by specialists. In this case, applying the composition with a brush or roller is ineffective, and the desired result can only be achieved using professional equipment.

Lakhta - penetrating waterproofing

One of the most famous and popular brands of domestic penetrating waterproofing is Lakhta. It is realized as a one-component compound. It is a dry mixture of gray color. It includes active chemical additives, portland cement and filler.

The principle of action is the formation of crystals inside the concrete, which fill the microscopic pores and voids. Crystals are formed as a result of the chemical reaction of the components of waterproofing and free lime entering into the concrete suction. Crystals do not dissolve in water and reliably protect the concrete from moisture penetration. Lahta is used for processing reinforced concrete, concrete, shut-off waterproofing ceramic, fireclay and silica brick, as well as quarry stone. It reliably protects the treated surface from moisture, acids, alkalis, oils and oil products. It is able to produce the effect of "self-healing", when the crystals cease to grow in the absence of water, and continue to grow when it appears, thus consolidating and thereby strengthening the structure of the concrete. Thus, the material is built into the structure of concrete, becoming its integral part. Waterproofing Lahta penetrates inside the concrete by 12 centimeters. The mixture is sold in packages of different weights.

This type of waterproofing has the following features:

- Complete absence of toxic constituents

- High resistance to hydrostatic pressure

- The treated surface becomes resistant to corrosion, retains water permeability, becomes more durable and well resists mechanical damage.

- The waterproofing does not lose its properties over time, its service life is the same as that of the treated structure.

- The mixture is used both on finished and under construction objects.

- Suitable for use in different climatic zones.

Waterproofing Lahta is recommended for use on objects that have the first and second groups of resistance to cracks. However, for this material there are several limitations in the application. For example, Lakhta waterproofing is not recommended for use in concrete with water resistance W2. including cellular concrete, for prefabricated foundation blocks, cement-lime, lime and gypsum plasters, as well as for unstable and weak surfaces. Special equipment is used to inject the solution under pressure into the brickwork.

All waterproofing operations using penetration formulations should be conducted with knowledge of the technology and with the availability of professional experience. And in cases when it is necessary to use special equipment, it is recommended to contact specialists.