About how useful the garage in the farm can not speak - it's a reliable place where you can store your car and repair it, communicate with friends, in addition - it is an excellent place for storing home billets and unclaimed household items at the moment. Since the main task of the garage will be to ensure the safety and security of the car, then its construction must be approached very seriously, a competent design of the project and selection of quality material will allow to operate this structure for many years.

Content

- 1 Projects of garages from foam blocks

- 2 Which wall material to give preference to

- 3 How to build a foundation for a garage of foam blocks

- 4 How to build a garage of foam blocks - choose a foam block and put the walls

- 5 The garage of foam blocks with their own hands - how to properly make the floors

- 6 We build a garage of foam blocks - which roof to give preference to

Projects of garages from foam blocks

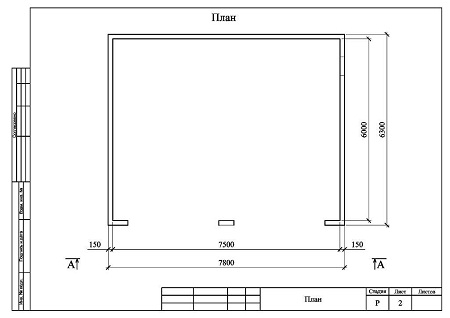

You can get a good garage project in many ways - if such a construction has been successfully built by neighbors recently - you can ask for drawings from them, if this is not possible - it's better to turn to professionals. When developing, it will be necessary to take into account the characteristics of soils in a given locality, it is impossible to do this on your own.

You can use a standard project, including a standard building, or order an individual - if any extensions and partitions are planned inside, two cars, etc.

With an independent drawing up of the construction plan, it should be borne in mind that the strip foundation is suitable for a garage with a basement or observation pit, but it is not recommended for high underground waters. The shallow-buried foundation also does not imply a significant increase in loads through the load-bearing walls, which are formed by using heavy reinforced concrete blocks to block the garage.

Which wall material to give preference to

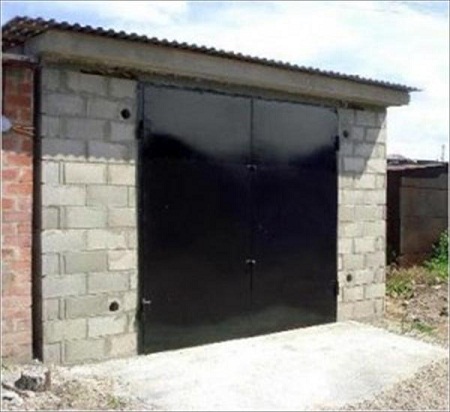

If a couple of decades ago, brick was the only worthy material for the construction of walls, today it can compete with modern varieties of building materials, including foam blocks. As their advantages can be noted:

- attractive low cost for consumers (by 36-40% below the cost of bricks),

- heat-saving properties, allowing to maintain a positive temperature with minimal heating,

- simplicity and high speed of masonry,

- a small proportion, which allows you to save a little on the foundation.

The material is vapor-permeable, this means that your favorite car will not be exposed to excessively humid air in the room and cause corrosive processes on the surface of its metal parts.

The strength of the foam block is high, ranging from 13 to 90 kg per square centimeter, depending on the class - the higher the class, the higher the density and strength of the material. The coefficient of frost resistance can also be 15-50 depending on the class. Due to the high strength characteristics of the material it is quite possible to build a garage of their foam blocks one-storeyed or with a mansard room.

How to build a foundation for a garage of foam blocks

Due to the low weight of the material during the construction of the garage, two fairly economical ways of laying the foundation can be used:

- lightweight pile-tape,

- on a sand cushion, shallow.

If the garage is built on a dense, not shallow or boggy soil, then there is no reason to spend money on laying a full-fledged deep foundation. It will be enough to cover it by half a meter, tamper at the bottom a sand cushion of 20 cm thickness and install a frame of reinforcement. Then you can fill concrete. In addition, with a sufficient density of soil (the walls of the moat should not fall apart), it is possible to apply a shallow method of pouring concrete. Formwork will have to be built only at a height of 20-30 cm above ground level - for pouring grillage.

When constructing a striped shallow foundation with the installation of the formwork, it is necessary to dig a trench wider by 30 cm than the foam block wall - on the sides of the grillage, in this case a zone will be created that allows compensating the pressure of the frozen ground.

Fill the concrete, it should be left for full hardening for 10-14 days, then you can proceed to waterproofing. It can be made with cold bituminous mastic, the grillage should be processed from the sides and from above. It is also possible to place the roofing material in two layers on top of the grater. Although the foam concrete has a closed cellular structure and is not very inclined to absorb moisture, but the waterproofing of the grillage and the concrete floor in the garage is still to be followed.

More complex in execution of the strip foundation on the piles, but it can also be applied on the topsoil. After digging a trench, the same as for the above-considered variant, along the whole perimeter with a motobor or manually make the wells to a depth greater than the seasonal freezing of the soil. The diameter of the wells should be about a third of the width of the grillage. The step between the wells should be from 1 to 1.2 m, in addition, additional drilling - in every corner.

As an insulating material, scraps of asbestos cement pipes or rolled pieces of roofing material are used. They are inserted into the wells, and several pieces of reinforcement are lowered there, so that their ends correspond to the height of the grillage, which will pour out of the concrete. Further work is carried out in the same order, that when laying the basement.

How to build a garage of foam blocks - choose a foam block and put the walls

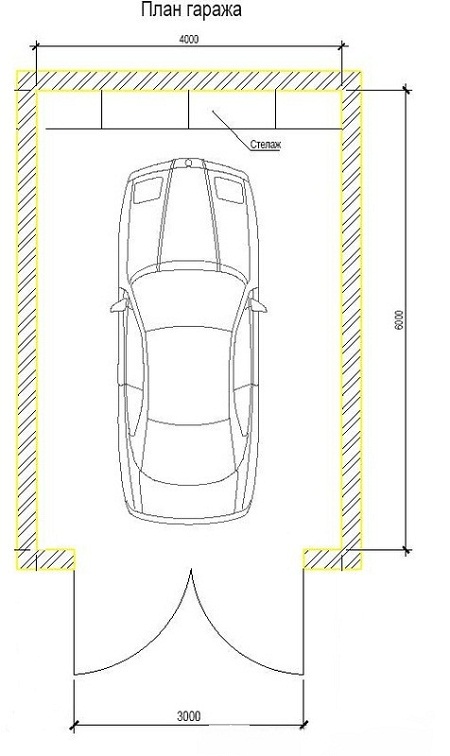

Experts recommend that when constructing a garage, use structural and insulating foam blocks of D500 - D900 grades, with a material density of 600 to 800 kg / cubic meter. Penoblok of lower density is too brittle. Depending on how warm the walls of the garage should be, you can buy a foam block - usually 20x30x60 cm, warmer - 30x40x60 cm.

Calculate how many foam blocks you need on the garage is not difficult. With a recommended wall thickness of 20 or 30 cm, blocks of precisely specified thickness should be purchased. In the calculation, the dimensions of the future construction are used, for example, when constructing a garage 4x6x3 m, the perimeter of the building is 4x2 + 6x2 = 20 m, dividing it by the length of 1 block 20: 0.6 = 34 pcs.

Then the number of rows is calculated: 3: 0.3 = 10 rows. Multiplying the obtained figures get the approximate number of blocks required for the entire building. From the received 340 pieces. you can subtract the number of blocks that make up the area of the gate, door and window openings. If partitions are to be built in the room, you should determine their area and add the necessary amount of material, calculated in pieces. It should be borne in mind that the actual consumption of blocks may be somewhat larger, i.e. the figure is rounded up.

In order to get "warm stitches" for masonry, you should use not ordinary sand-cement mortar, but perlite. The price is quite affordable, but the masonry array will get evenly warm, without bridges of cold.

To prepare a solution with perlite mix (in parts):

- perlite - 1,

- cement - 1,

- sand - 2.

Water is added in small portions until the mixture reaches the state of thick sour cream. For masonry, you can also use a mixture of thermosov, which is sold in dry form.

Even with the creation of a high-quality, level foundation, the first row of blocks is laid on a layer of mortar up to 3 cm thick. This will prevent the appearance of cracks in the event of point loads.

Since the foam concrete is a fragile material, when laying walls, the plastic reinforcing mesh (or galvanized) should be laid every two rows.

Noting the place where the gates will be located, they are installed on the foundation, they are convinced of the correctness of their vertical and horizontal position, fixed with the help of temporary slopes.

To obtain a strong and stable wall of the walls, it will be necessary to perform the dressing of the joints. For a foam block this is very important, because of the large size of each block.

After forcing the walls to the level of overlapping, you should stop the work for a few days - until the solution is completely hardened and gain strength. Further work is carried out depending on what materials will be used for overlapping.

If it is planned to build a two-story garage or to cover one-story reinforced concrete panels, then on the upper edge of the masonry make a 20-cm reinforced reinforced concrete belt, it will prevent the possibility of damaging the foam blocks with heavy panels and give the walls a certain stiffness.

The garage of foam blocks with their own hands - how to properly make the floors

The construction of floors is a process though labor-intensive, but not particularly complicated technologically. First, remove 20 cm of soil, level the ground, cover with sand and compact. Next, waterproofing with a thick polyethylene film, the edge of the film should be made 20 cm on the foundation - in this case, exposure to ground moisture will be eliminated.

Reinforcement is carried out by a masonry net with a 10x10 cm cell. As a protective layer, concrete is used for concrete. After pouring a 10 cm rough layer, the screed is left for a few days to solidify. Next, put the beacons, the distance between them should match the width of the trowel, fill the screed, aligning well.

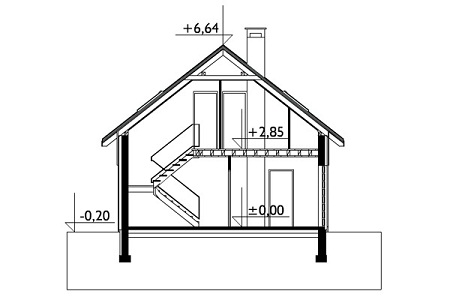

We build a garage of foam blocks - which roof to give preference to

The roof of the garage can have a different design:

- one-run, made on wooden beams,

- gable type hipped type,

- mansard.

If the area of the garage is small, but it is planned to equip the workshop, it is more profitable to use the roof roof attic, although its construction will have a higher cost. The advantage of a warm garage with this type of roof will be the possibility of operating the structure throughout the year.

Installation of the roof is carried out in this order: first, the joists are laid on the walls, then the rafters of the roofing structure are fastened to them. First of all, the front and rear walls are assembled. After the assembly of the outermost trusses, the remaining ones are installed by stretched twine. Next, they build a crate and spread the roofing material. It can be metal or slate.

If a cold building is planned, then it will be enough to knock the ceiling with plywood or edging boards. If you plan to install a thermal insulation system, you will need to lay a layer of vapor barrier and insulation - mineral wool or ecowool, at least 10 cm thick. Warm the walls of the attic from the inside can be the same materials, covering them with a vapor barrier film.