Modern construction involves the use of a wide variety of finishing materials, both natural and manufactured from products obtained from the processing of plastics. Among the practical materials, it should be noted plastic lining, which occupies a rather high place in the popularity rating. It has quite an attractive appearance, it serves a long period, and the price of plastic lining will please even those who are going to make repairs with a very modest budget.

Content

What is plastic lining

For the first time such material began to be used for sheathing of wagons used on the railway. Thanks to this, it got its name. In appearance, the board looks like an ordinary board with a smooth and even surface. In the lateral parts of it there are grooves intended for connection with similar neighboring parts.

Do not perceive the lining of plastic as an ordinary sheet material - in the interior of this panel are located separately along the honeycomb, due to which it has a high degree of isolation.

To create such plastic panels, PVC is used, this improves the following performance properties:

- long operating period - the material does not rot, does not change its appearance;

- does not leak and does not absorb moisture;

- the material is not subject to the harmful effects of different temperature regimes - the performance characteristics remain unchanged at both -50 degrees and at +50 degrees;

- is not susceptible to ultraviolet radiation and other atmospheric influences;

- famous for its incompatibility;

- a wide range of colors allows you to choose the material for any interior.

There is also one comparative disadvantage of the lining. Its surface has low mechanical endurance. The maximum weight that can be hung on it is a cargo that has a mass of not more than 1.5 kg. Accidental impact, even a small force, will cause a fairly noticeable dent on the surface.

There are a lot of options for using plastic lining and it makes no sense to describe them. An important advantage of the lining can rightfully be considered the fact that its installation does not involve any additional surface preparation. Already installed lining perfectly excludes any irregularities or defects present on the surface of the ceilings or walls. Use it to ennoble vertical and horizontal surfaces.

Most often it is used for sheathing corridors, balconies, verandas and so on. Especially practical it will be in the toilet or bathroom, the microclimate in which is characterized by high humidity, because it is water resistant. With regard to maintaining cleanliness, in the premises lined with lining: there is no need for special physical, time and financial costs, it is enough to perform the usual wet cleaning.

Plastic lining - how to choose the right one

Before buying this building material you need to familiarize yourself with its varieties, namely - the lining can be wooden or plastic.

The wood is mainly made from coniferous or deciduous trees (cedar, alder, beech, ash and others). Thanks to the use of natural materials, the look is admirable and fits perfectly into any interior. The room with the decor of natural vagonki breathes, thanks to the creation of a natural microclimate. It happens because the tree has the ability to absorb excess moisture when it appears. And when the moisture is not enough, it emits it. In addition to this, in a room with such decoration there is a special pleasant aroma, thus creating a cosiness and naturalness.

Plastic lining, in contrast to wood, is made by combining additives and PVC resins. All the components from which it is made are environmentally friendly and non-flammable. This material passes fire and hygienic certification.

Plastic lining has the following differences in form:

- Panel paneling is an imitation of a wooden beam. The paneling with this kind of profile can be both plastic and wooden.

- Euro-paneling. It differs from the usual connection. Ideal for exterior plating of almost any structure.

- Lining is calm. It is mainly used for interior decoration of walls and ceilings. A feature of this finishing material is a smooth surface, because there are no mounting grooves on the front part.

- Block house. It has rounded outer forms resembling logs. Its fastening is performed by lateral grooves. Finishing such material can be performed both inside and outside the structure.

On how to choose the lining and what to look for when buying - on the video:

Plastic lining for exterior work

The building material with these characteristics is ideal for exterior decoration of buildings, for example, in a private plot. In the composition of the material for the manufacture of panels, manufacturers add a special component, which maximizes its frost resistance. In addition, the plastic panels are very flexible and allow the use in the most difficult and difficult to configure locations.

In order to mount the plastic lining, at hand you need to have the following tools:

- electric jigsaw or hacksaw,

- drill,

- screwdriver,

- a hammer,

- level.

With regard to materials, you need to purchase the following: plastic lining for external or internal works, depending on the location of the planned finish), material for the construction of the battens (wood beam), screws, dowels, profile.

Finishing with plastic lining

The technology and sequence of installation of the outer and inner lining is similar. Directly it is necessary to begin work with bringing the surface into the proper form. First of all, it is necessary to remove the falling off pieces of plaster (or other material, which was previously coated with the surface) from the surface.

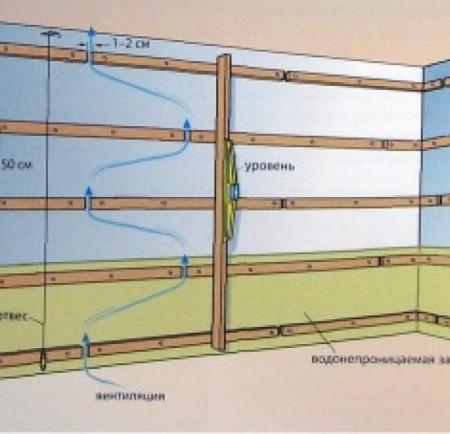

The next stage is the preparation of wooden beams. They need to drill holes for self-tapping screws at a distance of 50 cm from each other. If the lining is installed on the outside of the building or in premises with high humidity, the beams should first be treated with linseed oil or a layer of paint applied. Often practice installation of an aluminum profile.

After that, you can mount the bar on the surface to be trimmed. It is recommended to make holes for dowels beforehand. The gaps between the bars of the battens should be less than one meter. All the bars should be exposed in a single plane. Check this will help level. After that, along the perimeter, the profile is fixed.

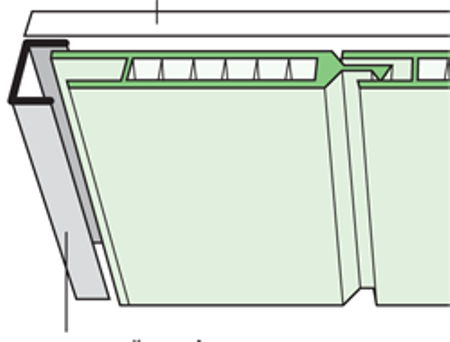

To begin with, the lining of the lining is done, with the help of a hacksaw or a grinder cut off excess length. Then, one end of the panel will need to be inserted into the starting profile, the panel itself should be slightly bent and inserted by the other end into the same profile fixed on the opposite side. Pulling the panel to the edge of the wall (ceiling), the third edge of the panel is inserted into the groove of the profile. The fourth side should be fixed on the ceiling (wall) with the help of self-tapping screws or panel fasteners. In order not to damage the panel during installation, it is preliminarily marked and drilled holes (inside the groove), screwing into it a screw with a press washer will be much easier.

It facilitates the simplification of mounting the presence of grooves along the perimeter, they allow you to quickly insert the next panel into the groove of the previous one, the collected surface is solid, the joints on it are almost invisible. If the panel has a solid color, then the need to select adjacent panels is no longer necessary.

It should be noted that when using panels with patterns, the material consumption will increase somewhat, some of the sheets will be waste. To accelerate the installation for screwing screws you can use a screwdriver.

Watch the video about installing a plastic lining:

https://www.youtube.com/watch?v=Epb2qP_T_eY

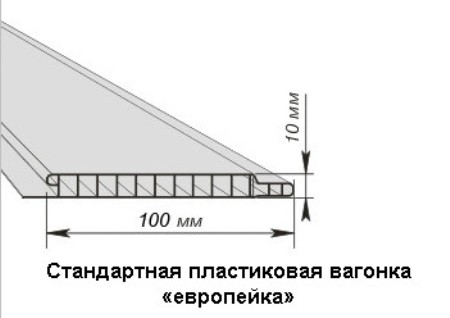

Dimensions of plastic lining for walls and ceiling

On sale there is a lining specially designed for exterior decoration. It has standard dimensions: length - six meters, thickness - ten millimeters, width - one hundred millimeters. Installation of this lining is unproblematic. If necessary, it can be cut. Special tools for this do not need, it is enough to have at hand an ordinary hacksaw or a Bulgarian.

For interior finishing, a special seamless plastic lining is usually applied to the ceiling. It helps to create an interesting and unusual interior. The given building material is issued in different colors, thus, it has a glossy shine.

With regard to the dimensions of seamless lining, this is not the case here. It can be of different lengths (2.7 m, 3 m, 6 m), different widths (100 mm, 250 mm, 380 mm respectively). Any of the variants of the lining always has a standard thickness of 10 mm.

Choosing a lining, for example, for the lining of the ceiling, it is better to stop on the panels with the maximum width. In this case, in addition to the lack of seams, installation will be performed much faster.

As already stated earlier, the lining of all sizes and types is mounted according to one principle. The only choice to be made is to decide which material to make the framework for fastening the lining. Wooden bars - an option is not bad, but not durable. There is no bad alternative (especially for rooms with high humidity or external work) - to build a frame of aluminum profiles. They do not rust and are strong enough.

When planning the finish with plastic lining for interior work, it is worth considering the dimensions of the panels used. When the width of the material used is 380 mm, experts do not advise making fastenings, from an aluminum profile or a wooden block, at too close a distance. In cases where the use of a narrower lining is planned, the distance between the fastenings should be correspondingly smaller than when fastening the lining with a width of 380 mm.

And now let's see how to properly trim the balcony with a lining: