Whatever you do for the sake of your favorite car! Even a compact and convenient observation pit. It is not difficult to create a pit, the main thing is to properly equip it, and this will require the necessary engineering communications. The friendly "interface" of motorists in this matter is always open: he did it himself - share it with his comrades. What do the builders and motorists advise or do the inspection pit.

Content

How to start the device

Most motorists, on their own territory - the garage, are inclined to the unanimous opinion that the garage can not be imagined without a viewing pit.

According to the rules, a properly arranged observation pit in the garage will make it possible to repair or prevent the car in a quiet working environment.

But it is necessary to make a hole for inspection according to the recommended rules, excluding the possibility of water leakage, because there will be constant contact with the ground.

In order to equip the pit, it is necessary to plan and build it in accordance with the technological process.

How to plan an inspection pit

dimensions and markup

Planning and equipment of the inspection pit with their own hands must be done, focusing on the car brand, measuring the distance between the rear and front wheels.

Therefore, the width of the observation hole is assumed to be less than this distance for the safe entrance of the car. The approximate width of the pit is from 70 to 80 cm. The length of the pit must be calculated along the length of the car, taking into account one meter for descent and ascent. In practice, the length of the pit is no more than two meters. The depth of the inspection pit is made from the calculation of the growth of the motorist with an allowance of 20 - 30 cm.

Helpful Tips

To make sure that the small pit is no longer adapted and uncomfortable than deep, go to the owner of the constructed pit. "Undercutting" a small pit is unlikely to happen. Determine with the marking on the terrain in someone else's garage, in order to exclude possible errors when equipping your pit.

life support of space

Inspection pit is exaggerated can be considered a working basement, therefore, it is necessary to provide and ensure:

• lighting and ventilation

• waterproofing and thermal insulation

• niches for lighting installation.

After the planning and layout of the inspection pit in size, you can proceed to the stage-by-stage construction, which begins with the preparation of the excavation.

Technology of construction of the inspection pit

The construction of the pit for car inspection must be carried out in stages:

• excavation

• Arrangement of floor and walls

• installation of niches and wiring

• arrangements for the safe organization of work.

foundation pit preparation and waterproofing

Digging and preparing pit for the pit will have to be done manually. It is necessary to dig a volume of the earth, to calculate which is simple enough: multiply the length, width and height of a pit of rectangular shape. It is this amount of excavation that will have to be "shoveled". It must be remembered that when preparing the foundation pit, the thickness of the laying and concreting of walls, as well as the bottom, is added to the working dimensions of the inspection pit.

floor and wall installation

For the arrangement of walls and floors it is necessary to make a waterproofing with traditional materials and method. The bottom of the observation pit is concreted and after the concrete has dried, the formwork for wall pouring is installed.

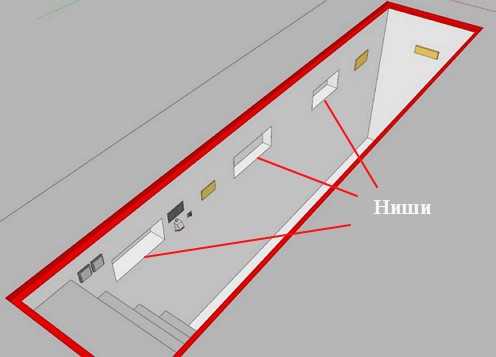

When repairing or preventing the car, it is necessary that the instrument is literally at hand: he dropped his hand and took out what was needed. Therefore, the side walls are equipped with niches at a convenient level.

During the installation of the formwork, there are niches and openings for electric lighting.

The wiring for lighting the observation pit is preferable at this stage. The electric wires are placed in a metal corrugation.

Helpful Tips

A well-considered stage of the formwork construction will help to facilitate the subsequent arrangement of the pit. Niches for installing lighting and process tanks (waste oil and grease) should be arranged at this stage.

The supply of communications for ventilation of the inspection pit is produced in a plastic pipe with a diameter of up to 100 mm, which has no bends. The pipe is placed in concrete during pouring. It is also necessary to arrange a pneumatic line throughout the entire length of the pit with several outlets of air. The wiring harness and lighting switches are located outside the observation pit near the stairs.

Before concreting the walls, we produce their reinforcement with a grid with cells 100x100 or use a road masonry grid.

Before pouring concrete, the edging is installed around the perimeter of the pit from the steel corner.

To reinforce the frame design, reinforcing bars are welded to the corners, which must be included in the formwork. The frame is fixed at the floor level of the garage itself.

Wall pouring is recommended with a layer of 100-200 mm. Pouring must be done in a continuous way with periodic compaction of the concrete layer.

After the final drying of the concrete layer (which is 3 weeks), the formwork is removed and the walls are lined. You can wall the walls of the pit with tiles or paint with a light tone.

Helpful Tips

Facing the tile for the pit is recommended to choose not slippery to the touch and not shiny. The hygroscopicity of the tiles should be minimal.

Light single-color matte walls will best enhance the illumination of the car and work will be more comfortable.

It is also recommended to use fluorescent lamps, because the light flux from them is more intense and uniform.

After successful repair in non-operating condition, the opening of the inspection pit must be closed, eliminating the possibility of foreign objects getting there and the possibility of an accident.