When replacing plastic windows, even if the work is done by professionals, inevitably there will be more or less destruction in the area of the window opening: cracks or potholes, to give the window slopes a neat appearance can only be by properly sealing these defects.

Content

- 1 Slopes on plastic windows - what materials can be used

- 2 Features of windows finishing with plastic slopes

- 3 Finishing the slopes with your own hands - the order of the work

- 4 A few recommendations from specialists about the decoration of window slopes with plastic

- 5 Finishing of window slopes inside by plastering

- 6 Window slopes of plasterboard - a traditional option

Slopes on plastic windows - what materials can be used

To finish the slopes proceed after the installation of new double-glazed windows. Materials at the same time can be used very different, their choice is influenced by:

- climatic features of the area,

- willingness to spend this or that amount of money,

- special requirements for design.

Also, the slopes can differ in the shape, color and texture of the material. Usually the following materials are used to upgrade the window opening:

- cement mortar, followed by painting the plastered surface,

- gypsum board, followed by puttying and painting,

- natural wood, which after installation is opened with varnish,

- sandwich panels, MDF, plastic.

The most expensive of the listed options - using natural wood, the material itself has a high cost, and it's unlikely that you will be able to carry out quality work on its installation with your own hands, and the work of masters is not cheap.

Features of windows finishing with plastic slopes

All other materials cost are more modest, works on their installation do not represent special complexity, so that the finishing of slopes with their own hands - the task is quite feasible. Since the window bags, which are now installed everywhere, are made of plastic, the slopes of the same material look like a logical continuation of them.

Among the positive moments in the installation of plastic slopes can be called the following:

- with a plastic double-glazed window they represent a single structure that looks good in a room with any interior,

- low cost,

- the ability to perform installation work for 3-4 hours,

- ease of cleaning from contaminants,

- long service life,

- the ability to purchase plastic of any desired shade.

Specialists warn: slope finishing can be started no earlier than 36 hours after the installation of the double-glazed windows - so much is required to solidify the foam.

During this time it will be necessary to prepare materials and tools for work. Buying plastic should not be stingy - good quality products will last longer, and the look will be more attractive. Having saved in the beginning on purchase of a material, in a consequence it is possible to receive weight of the problems connected with repair of the damaged fragments.

Acquire plastic less than 8 mm thick is not recommended. The width and height of the plastic panel must correspond to the same dimensions of the slope planes.

In addition to plastic you will need:

- F-shaped profile and starting strip,

- cement mixture,

- clips, self-tapping screws, silicone, assembly foam,

- a heater, an adhesive tape.

You will also need tools: spatula, tape measure, hammer, screwdriver, gun for applying silicone and foam, drill, rags.

Finishing the slopes with your own hands - the order of the work

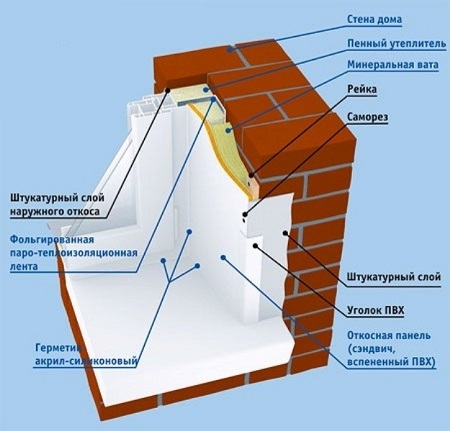

It is recommended to start work by removing the conveyor belt from the profile surface. Prepared cement mortar should be carefully closed all the cracks formed from the outside. This will help to seal the assembly seam, as well as protect the foam from exposure to sunlight, which can cause its destruction. Use for work can not only cement mortar, but any solution for outdoor work. If desired, the resulting surface can be covered with paint, but five is designed for outdoor work. The finishing of window slopes from the outside ends here.

Next, you can begin to finish the inside of the slopes with plastic. In accordance with the measurements, the starting strip is cut off, using self-tapping screws fastened to the slopes along the entire perimeter of the opening. It will serve as a base for installing plastic panels.

Panels for slopes are prepared as follows:

- cut a piece of plastic, corresponding to the size of the upper part of the window opening,

- is installed in the grooves of the starting strip,

- preparation and installation of side panels is carried out in a similar way.

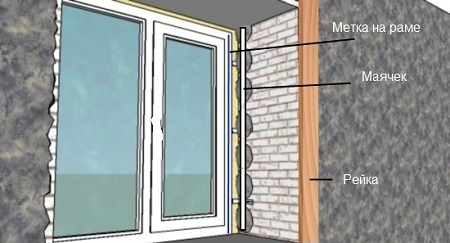

Quality control of the installation is carried out using a building level or a plumb.

The frame is designed in such a way that:

- slopes on both sides of the window had the same size and angle of rotation,

- the width of the opening formed between the base base and the plastic was about 20 mm - it will need to be filled with foam,

- protruding from the plane of the opening of a part of the plastic panels must be carefully cut with a construction knife,

- to hide the unevenness of the slices, it is recommended that in each corner set the trimming of the start profile.

Next, you can start making fancy edging from the F-shaped profile, start working better with the top element. At the points of joining, the F-shaped profile is filed at an angle of 45 degrees. With particular severity, the process of filling foam between the plastic and the base of the opening should be considered. The amount of foam should not be too large - when hardening, it will increase its volume, which can cause deformation of the material.

Apply foam along the perimeter of the window at the base, then - along the angle of the slope, in the resulting space it is required to install pre-prepared lengths of the F-shaped profile. They are convenient to fix with tape.

After about 20 minutes, the foam will harden and give the structure sufficient rigidity. At the final stage of the work, it is recommended to smear all the existing slots with a special sealant.

To improve the adhesion of foam with other materials, you can moisten their surface. One should not forget that it will require the concealment of defects that appeared under the sill and tide. In conclusion, you can clean the surface of the sill and installed slopes from building dust or accidental contamination with a soft sponge or rags.

A few recommendations from specialists about the decoration of window slopes with plastic

To make the slopes beautiful and reliable:

- use for manufacturing the material of the highest quality, corresponding to the color of the window profile,

- to cut PVC-panels follows an electric jigsaw or a mounting knife,

- so that plastic deformation does not occur, it is recommended to use a mounting foam with a low coefficient of expansion, and also to fix the slope fragments in the correct position for the setting period, i.e. for 10-15 minutes,

- if it is required to perform thermal insulation, then it is laid in the gaps between the panels and the base base, before the foaming,

- do not forget about the need for plastering part of the opening under the windowsill.

As you can see, window slopes made of plastic - a task that a person can fulfill without the special experience in construction, only the ability to make correct measurements and handle construction tools.

Finishing of window slopes inside by plastering

If the above method requires some insignificant material costs, then the plastering will cost even less - materials will only require puttying, the most convenient is the polymer gypsum mixture for internal work. Dilute it with plain water.

Work begins with a thorough cleaning of the surface to be cleaned from dust and lacerated plaster residues, to ensure better adhesion, the seams between the slope planes and the walls expand to 10 mm. First plaster is applied to the walls, then to the slopes. Apply each subsequent layer of plastering only after the complete drying of the previous layer. Plastering of the middle of the window aperture and pockets is carried out in accordance with the generally accepted rules for the creation of external and internal angles.

The need to wait for time to dry up each layer significantly prolongs the time of work. If there is a need for thermal insulation of slopes, the gaps between the wall and the double-glazed window can be filled with various insulation materials, including an antiseptic paste or felt. They are wetted in gypsum mortar and stacked around the perimeter of the window frame. It will be necessary to ensure the presence of a distance of 20 to 30 mm to the ends of the window box - they will serve as grooves for laying a solution. Apply it in a layer of 5-7 mm at a time, then wait for drying and continue working until the groove is completely filled. It is recommended to level the layers from the bottom up, use a half-circle to align the lines.

In order to preserve the sunrises of the window it is recommended to adhere to the initially existing angle between the wall and the window box. The angles on both sides of the window box should be the same. To ensure the horizontal line formed by the wall and the upper part of the slope, as well as walls and lateral parts thereof, it is possible to fasten evenly ribbons along the edges with nails or gypsum plasters, checking the horizontal or vertical position by means of level and plumb.

For uniform application of the solution to the slopes, use a wooden muzzle with a rounded handle. The length of the malk must correspond to the width of the slope. To make the tool move freely along the slope from one end, a small cutout is made. At work, the malk is installed at one end onto the window box, the other to the rack.

To equalize the edge created by the wall and the slope, you will have to wait until the solution seizes. Then on the surface put a cover layer of plaster and rub it. In order not to crush the child, flat foxes or curvatures are used. You can remove the slats only after the plaster layers have dried.

Specialists consider the work to be of high quality in the event that the angle is grounded without namaz, and the covering layer has a thickness of 22 mm, it is recommended to withstand the same on all planes of the slope.

Window slopes of plasterboard - a traditional option

This is exactly what I want to call this truly universal option. It is appropriate to look with any double-glazed windows, the cost is low, the complexity of the construction it can be evened with plastic slopes. For work, the residues of a moisture-resistant gypsum board are usually used, but if this is not available, then you can use a conventional wall, but it will require several layers of primer or moisture-proof composition. Such precautions are mandatory, because windows and slopes under certain circumstances can serve as a surface for the condensate to settle.

The procedure is as follows:

- After the preparation of gypsum plasterboard slopes, stirring is started for a special adhesive compound designed to work with gypsumcoat.

- On the underside of the workpiece, glue is applied, the height of the tubercles of which should be of the order of 100 mm and the diameter from 100 to 150 mm. Lapuhi should be located at a distance of about 250 mm from each other.

- Begin the work with gluing the upper part, it is installed in the opening, pressed to the base until the line of slope of the sheet will match the line-marks.

- If excess glue comes out - they are immediately straightened at the end of the gypsum cathode sheet. Precisely on the same principle glued side slopes. After 20 minutes, when the glue thickens, all the voids that have been found need to be filled with the same adhesive.

Masters recommend:

- do the work together - gluing the side panels will be easier if someone will hold the already glued upper,

- the quality of installation is best monitored at each stage of operation, visually and using a plumb and level,

- gluing slopes should be remembered that they should not fit too tightly to the mechanism of the loop.

In the process of final finishing, the joints of the lateral slopes with the upper one should be plastered. If there are unevennesses in the places where the glue is laid, they are eliminated by the treatment with a grater designed for gypsum board work, the grooves found are filled with filler. After drying, putty places are treated with a small grater. When all the corners and the surface of the slopes take an ideal look, you can proceed to priming all surfaces. After it dries on the slopes, paint is applied. The best option - the use of water-based compounds. They should be applied by special rollers, which make it possible to obtain an invoice surface, or with double brush.

After the arrangement of slopes inside, it is necessary to finish the window slopes from the outside.