At the word "bamboo" there are tropical associations: evergreen jungle, tall grass, heat and summer. This amazing plant really grows in hot countries and, due to its resistance to moisture, it is used in many ways. Bamboo is made furniture, dishes, interior items, used as raw materials for fabric production, including for the cultivation of wall panels.

Content

Natural bamboo in the production of wall panels

Natural bamboo is an excellent building material. Choose it for production of wall panels. Bamboo is very pliable in work, it can be easily polished, cut out thin fibers for weaving, processed at your discretion.

Bamboo wood for wall panels is initially handled. The basis is taken by a young growth of bamboo. It is treated with moisture, then plexus is made. Further, intensive drying is required under hot press and acrylic treatment. At the exit the panels are opened with a varnish, so that they serve their owners as long as possible.

Despite a number of procedures, the sheets turn out to be thin. Their thickness is only 1 mm. There are also more dense plates up to 7 mm. In the production of bamboo is divided into several types of thickness, and the panels have a different type of weaving and proportionality. Conventional bamboo panels are produced according to the standard no more than 120 * 240 cm.

The most high-quality material are bamboo panels from Thailand. Material for the manufacture of environmental mats comes from many tropical countries, among them: Laos, the Philippines, America, Oceania, China. Natural bamboo is rarely amenable to processing. From production it is produced in unpainted natural form. In the future, various decorating emulsions and processing methods can be used to create a suitable kind. Only occasionally are the panels treated with roasting, colored lacquers and other coloring pigments.

Types of bamboo panels

Bamboo panels though have not so many colors, but differ in several types. First of all, the canvas for the walls and for the ceiling is selected. Accordingly, on sale you will find its different sizes. Here are the parameters of wall bamboo panels:

- 60 x 60 cm - small slabs suitable for ceiling design;

- 100 x 190 cm - ideal for wall mounting;

- 120 x 240 cm - suitable for pasting walls.

In terms of thickness, several types of bamboo panels are distinguished;

- Single-layer - layer thickness not more than 1 mm. Very thin structure is practically not used for wall design. Only in the places of transition of corners, as well as for pasting doors, cabinets. In places where there is a very flat surface without flaws, and where flexibility is required;

- Two-layer - such panels glued walls and ceilings, they are well cut with a construction knife or ordinary scissors;

- Three-layer- Easily mounted on the walls due to its sophisticated structure. Lends itself to tools such as scissors and a penknife;

- Five-layer - The thickness is 5 mm. To work with this kind of bamboo panels, you can use metal scissors, a wood hacksaw. As a decoration, this mat is placed over an unevenly applied plaster. The material will somewhat hide the defect;

- Seven-layer - the densest sheets of bamboo. Their thickness is 7 mm. They are not as easily cut as the above listed types of bamboo material. In work with dense panels use an electric jigsaw or a hacksaw for metal. Such panels can hide a slight unevenness of the wall surface.

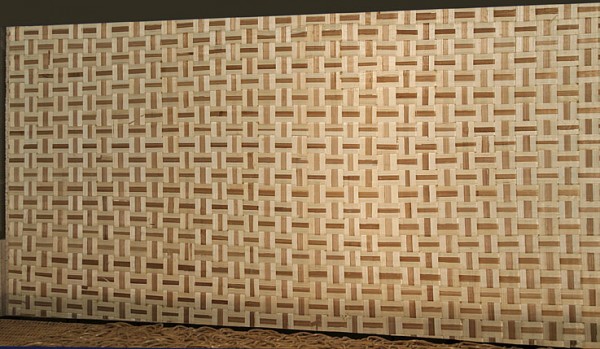

3d panels of bamboo

Remember polypropylene plates, which in the 90's glued everything to the ceiling? They were replaced by more modern 3d panels made of bamboo. Mount them both on the ceiling and on the walls. Unlike their predecessors, they are made entirely of ecological material - pressed bamboo. On sale are more often unpainted slabs. The calculation is that afterwards they are glued together, the seams are smeared with putty and will give the necessary color in accordance with the interior.

Plates of bamboo come in several sizes:

- 300 * 300 mm;

- 500 * 500 mm;

- 625 * 800 mm.

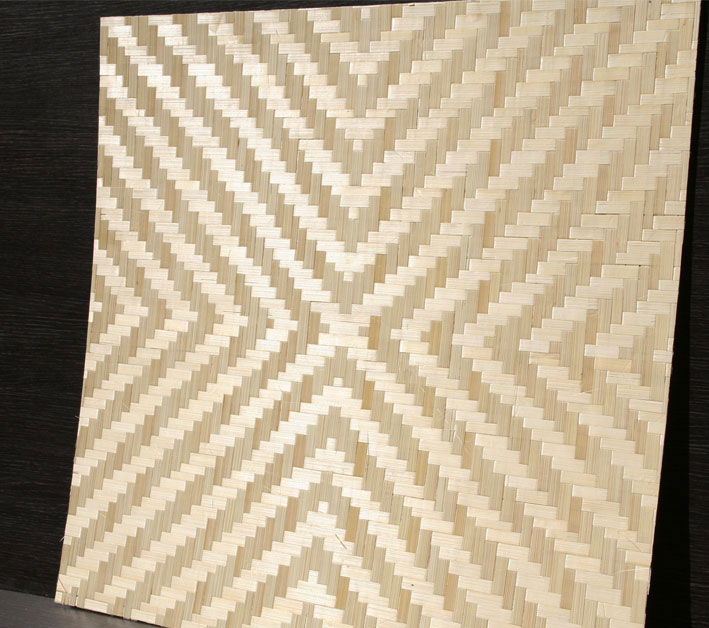

The thickness of the bamboo material is not more than 1.5 mm, but the texture itself can occupy up to 25 mm. Mounted plates on a previously prepared wall, without irregularities. Otherwise, you will not get even joints. The material has a convex texture due to which it got its name - 3d. If there are limitations with the color of this finishing material, then there are no difficulties with graphic execution. Here and various figures in the form of circles, zigzags, straight lines, broken lines, metamorphic images. Mostly produce panels with drawings that do not need to be docked, but there are also those that fit together as a mosaic.

The shape of 3d panels or 3d eco-panels, as they are called, is rectangular or square. This "facing" can easily fit into any interior. Simple and uncomplicated patterns in appearance, give ease to the room because of its bulge. The panels look completely different when using the backlight. Even the patterns do not seem to be the same as before.

3d eco-panels are suitable for finishing, both the whole room and individual zones. They are convenient to allocate sectors of the room, office, bar. A small application of bamboo looks like a wall panel, and walls with an acting abstraction, as something that connects reality with something cosmic.

Sale of such ecological tiles from bamboo in building stores. The price goes for 1 piece. The material is, in fact, inexpensive. 1 bamboo panel you will cost from 70 rubles.

Bamboo wall panels advantages

- Bamboo panels like to use in a modern interior primarily for their natural origin and ecological purity. Plates made of natural material can be mounted even in the children's room. They do not release toxic compounds into the air, but rather fill the atmosphere with natural flavors;

- The cereal in the natural environment is very strong, which is reflected in the panels themselves. They can be placed in places where there is a large crowd of people: in cafes, restaurants, hotels. The treated material is practically not vulnerable to minor damage. It will last several decades;

- This material is chosen not only for interior decoration, but also for outdoor. Bamboo, which is covered with a varnish layer, is resistant to sunlight and moisture. Therefore, the panels of bamboo are perfect for gazebo, summer house or recreation area;

- Bamboo is universal and can fit into any interior. Bamboo wall panels and 3d panels have a lot of textures;

- Plates of bamboo are easily mounted by themselves. In order to arrange them in your interior, you need to have a sufficiently leveled surface, mounting glue, screws, scissors, hacksaw or fret saw. And you can install slabs on almost any surface: on brick walls, and on gypsum board, and on wood chips, and even on concrete;

- When choosing such panels for your interior, you can hide some unevenness of walls, stains from putty, the remaining pieces of wallpaper that do not completely leave the walls;

- Panels from bamboo can be glued on either side. Both the front and the back are made in one version;

- When installing bamboo panels, you spend much less time than painting or pasting walls. This is due to the material's fusion and the minimum cost of working on the preparation of walls;

- Relatively low material cost.

Installation of bamboo panels

Preparation for the installation of bamboo panels should be carried out in several stages. It all depends on the type of surface to which you will attach the bamboo material, the thickness of the slabs and the degree of their processing.

surface preparation

Preparatory work before the installation of bamboo panels should be carried out the same as before the wallpapering. Only the requirements for leveling the surface will be significantly lower, since dense bamboo material hides minor flaws in the walls. Clean the surface of dirt, debris. If the wall has a significant distortion, then it is necessary to level the defects with putty or plaster. Then sand the surface with sandpaper and open with a primer. Because of this, it will depend on how reliably the panels are fixed and how long they will last.

material cut

Cutting bamboo panels can be made in any direction. In view of the fact that the bamboo was subjected to the processing of the press, its fibers are securely glued together and do not crumble under such manipulations.

Cut material can be conventional scissors (for single-layer or double-layer panels). If the plates of bamboo are more dense, then it is better to use a hacksaw or a jig saw. It is better to use a small tooth for the saw. So your panels will have a flat edge.

fastening of panels

Panels from bamboo can be fastened in several ways:

- for liquid nails;

- on self-cutters of small cross-section;

- for small galvanized nails;

- professional stapler.

Liquid nails will fasten the bamboo panel with the wall. Parquet glue is also suitable here, which is not inferior to the reliability of fixation, or any other glue of strong fixation.

Self-tapping screws and small studs will significantly increase the time for mounting the panels, but the fixation made in this way will be somewhat more reliable. As for work with a professional stapler, the panels will be fastened with metal staples and "shoot" to the surface.

Self-tapping screws, nails and a stapler are good for wood or plasterboard surfaces. For a brick and concrete wall, liquid nails or parquet glue are ideal.

work with panels

- Stitches at the joints of panels fill with a fine shpatlevkoj. After drying, treat the seam with fine sandpaper;

- When installing the panel, inspect both sides for stains and unevenness. Choose the side that is suitable for fastening. Visible defect can be removed using a grinding wheel or ordinary nazhdachki;

- To keep your hands safe, when working with bamboo, you should consider that it is pricked and can cut you, wear gloves. This protective accessory is sold in any construction shop. Better if the phalanx of gloves will be covered with a protective rubber layer.

panel protection

Many people think about whether it is necessary to treat bamboo panels with any protective solutions and which ones? First of all, the material must be protected from dirt. If there is no dust, splashes, permanent contacts with that panel in your room, then bamboo should not be processed. In the case where the walls are exposed to contamination, it is necessary to apply a protective layer consisting of water lacquer. This should also be done in those rooms where there is a lot of moisture. Apply varnish with a brush or roller.

painting panels

Because of its natural structure, the bamboo canvas has a light shade of wood. If you want to transform the surface and give it a different color, you should use colored varnishes. Evenly dye the surface you can only spray gun or spray.

Bamboo panels in the interior, photo

- Bamboo room - for those who love everything alive and natural;

- Bamboo panels at the head of the bed;

- 3d eco-panels for registration of a multimedia zone;

- Separation of the room into zones with pressed bamboo panels;

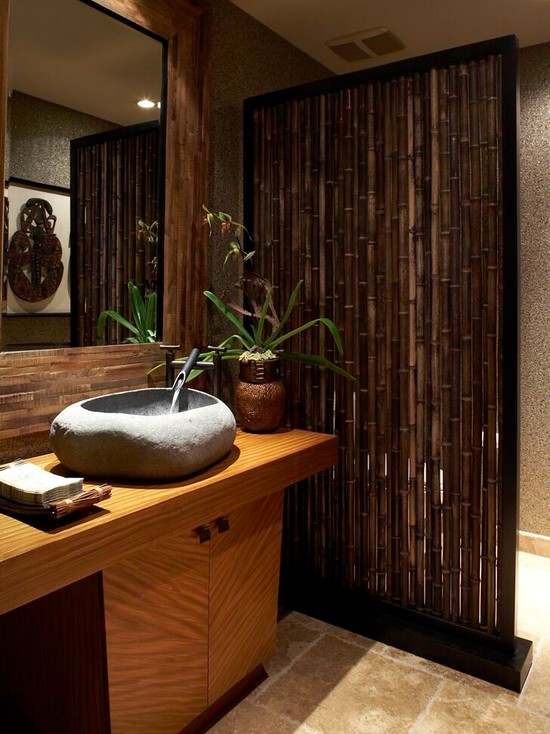

- Bamboo panels in the bathroom;

- Bamboo panels in the corridor;

- Bamboo panels in the kitchen.