The panel doors confidently conquer the expanses of apartments and country houses.

Why are such structures attractive? To put it bluntly, it's a simple build process, which you can do yourself.

Content

Choosing a shield door

Choosing a door for living quarters, we are guided by certain criteria, the fundamental of which are:

• the appearance of the door

• fabrication material

• cost and lifetime.

Of course, the main deterrent is the cost of the door. Therefore, the desire to buy a door is cheaper. A good alternative to expensive doors from a natural array are the panel doors. What is the design of the panel door and where can you use these doors?

As practice shows, shield (frame) doors are used for internal placement.

Construction of the panel door

hollow door

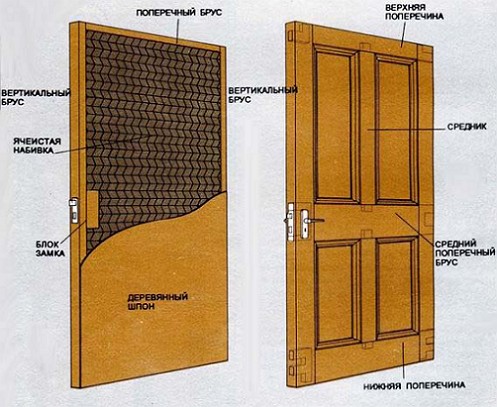

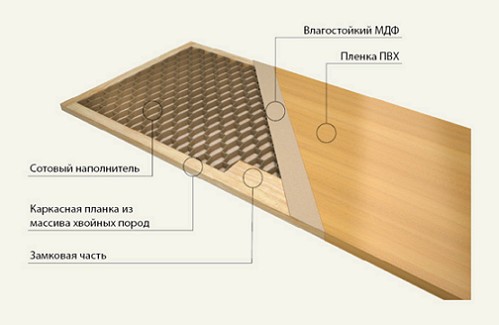

Doors, wooden panel or frame doors are a construction having an internal cavity filled with a special filler. The standard panel door consists of elements:

• side bars

• Cross bars (upper and lower).

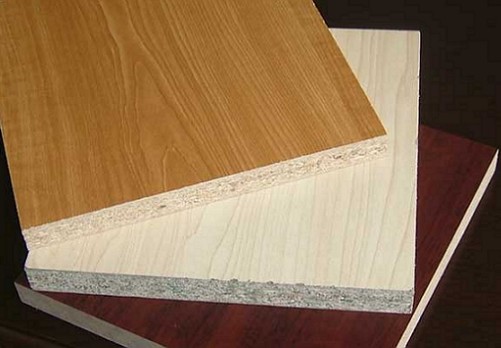

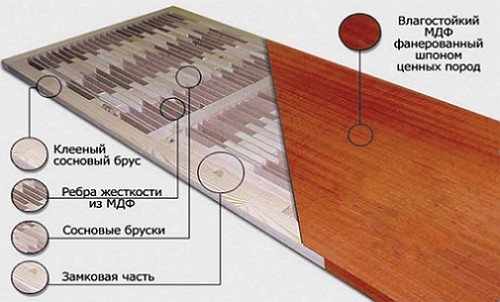

As a filler for panel doors is a multi-layer cardboard or MDF. The basis of the door is a frame made of a solid wooden massif. Basically, the aspen wood is used to make the frame. The frame is covered on both sides with sheets of MDF. As a finish, a variety of materials are used, namely laminate, veneer, PVC.

Between the bars of vertical and horizontal straps insert ribs of stiffness - slats up to 25 mm thick, which do not allow the curb to bend under their weight. Thus, the problem of removing internal stress in wood is solved. A blind door leaf has a certain configuration for the installation of glass or a panel of simple shape. Glass and panel are fixed on the canvas using traditional baguette. Here is such a simple and affordable design. A natural question arises: "Then why is the preference given to simple panel doors?". It is necessary to distinguish between panel doors - they are solid and hollow structures. Well, with the hollow, everything is very clear, hollowness requires filling, even a cardboard one.

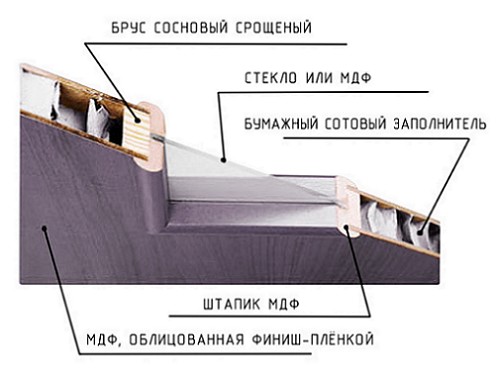

For hollow panel doors of interior rooms, honeycomb filling is used. Cellular filling is distinguished by the simplicity, ease and cheapness of the construct. Therefore, before the shield door to buy, it does not hurt to ask what method of manufacture has been applied. A cheap variant of the "wet" manufacturing method is distinguished by the quality of the cardboard and the size of the compression cell - the honeycomb. The size of the honeycomb can range from 10x10 to 40x40 mm.

The most significant is the finish of the door leaf. Therefore, the cost of decorative material should give an answer, buy an expensive high-quality door immediately or make cheap ones own.

In addition, for the panel door there is the possibility of glazing. Interior glazing significantly increases the cost of the door due to additional work.

Undoubtedly, the design of a solid panel door is more interesting.

What is a shield sheet, kindly tell a video.

solid panel door

Solid panel doors can be called a more perfect product.

As the elements that make up the solid panel door, use:

• 10 mm straight profile.

• 35 mm XL panel.

• multilevel profiles for giving the wing mobility

• Synchroporous material with improved design

• alternating panels with vertical and horizontal orientation of veins.

The quality construction of the panel door is continuous provided by a number of elements that ensure the removal of internal stresses in the tree. Internal tension in the tree is an inevitable process that occurs when making wooden structures of panel doors. How, perhaps, to avoid the natural displacement of wood over time?

In branded manufacturers of solid panel doors, this problem is solved by upgrading panels with a transverse and longitudinal arrangement of veins. This creates an amazing innovative design. The main emphasis is on the use of finishing with open pores. Panels of the panel door now combine a pleasant texture characteristic of natural wood. Designed using panels and colored glass, this panel door looks stylish and respectable.

If you are determined and want to make a solid panel door yourself, then you need to think through the whole technological process.

In the meantime, find out what the interior doors are. Perhaps the desire to make their own hands the shield door will pass.

How to make a shield door yourself

There are several ways to make a hollow panel door. One way is to glue the shield from special narrow rails. The other is by building a frame with the subsequent filling of voids with honeycombs. Solid waste is used as a honeycomb. The first method of manufacturing is labor-intensive.

Reiki will need to be calibrated in size, and then neatly connected to each other. For these purposes it is desirable to use special equipment - a conveyor press. Therefore, the best option is to make a frame as a supporting structure of the door.

The manufacturing process of the door will consist of the following steps:

• frame assembly

• gluing of plywood sheets

• securing the cladding

• filling the internal void.

The frame for the panel door is made of bars. For internal doors use bars with a section of 50x22 mm, which are connected to a spike or metal clips.

Then, the assembled frame is glued with plywood sheets, glued with glue, and attached with small nails. The lined frame is turned over and filled with an internal void. As a filler waste of lumber is used. In order to compact the connections, the assembled shield must be crimped and left to dry completely.

On average, the drying process will be up to 12 hours. After the final drying, the shield is strung from both sides and prepared for facing work. You can cover the panel door with veneer or melanin. However, this proposal is not strict.