Household heating boilers were replenished with new models - Galan electrode boilers, which have an obvious advantage. Unlike other heating appliances, the electrode boiler does not need to be coordinated with the installation according to the current "Rules". What is the model of the new boiler, and what conditions exist for its own connection?

Content

Galant boilers, operating principle, technical data and design

Electrode heating boiler is a TEN structure, equipped with materials from a European manufacturer. Recall that this is stainless steel grade AISI 316L and nichrome with increased load capacity, withstanding a long working cycle.

Principle of operation electrode boiler galan is to pass an electric current (electrolysis) through a special non-freezing coolant.

Electrolysis and heat transfer of the heated state of the electrodes are carried out at a constant current. The compact design of the heating blocks is distinguished by the small overall dimensions and weight of the boiler assembly. The coolant of the heating electrode system is antifreeze.

technical characteristics of electrode boilers

The main technical characteristic of the electrode boiler is power.

The range of electrode boilers is represented by models of the Hearth, Geyser and Vulcan.

The smallest boiler is a series CENTER, having a small power consumption (from 2 to 6 kW), designed to heat the area of 120, 230 and 280 cubic meters.

For example, electrode boiler Galan focus 3 has the following characteristics:

- overall dimensions: length 275 mm, 35 mm, device weight less than 1 kg.

- the power of 3 kW makes it possible to heat a room with an area of 120 m3.

Models GEYSER average performance have increased power - 9 and 15 kW with the possibility of heating the premises of 340 and 550 m3. Overall dimensions are 360 and 410 mm, 130 mm, weight 5 kg.

The most powerful models are VOLCANO, having a capacity of 25, 36 and 50 kW and are designed for heating of rooms from 830 to 1650 m3.

The linear efficiency of the electrode boiler can reach 96-98%. In relation to the traditional TEN, the efficiency of the electrode boiler is up to 50% due to the method of direct heating of the coolant.

design of electrode boilers

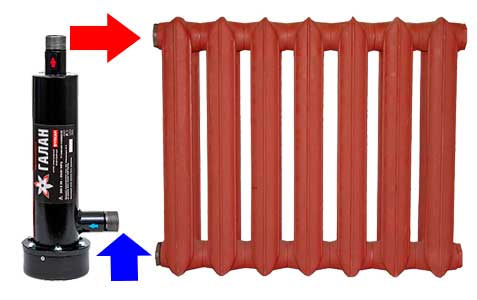

The first thing that catches the eye when looking at electrode boilers is an unusual design. Instead of a pot-bellied and voluminous boiler, long cylindrical structures with two threaded flanges, indicated by arrows of different colors (incoming blue and emerging red). The metal housing of the boiler can have a diameter of 40 to 100 mm and a length of 310 to 350 mm.

In the process of electrolysis and heating the coolant in the boiler, the internal pressure increases to 2 Atm. The heated water is pushed upward, providing the functions of the circulation pump. In addition, galan electrode boilers distinguish the availability of heating automation with a simple control system of the device.

Special attention should be paid to multifunctional control units designed to implement a certain algorithm for the operation of electric heaters. Installation and installation of an electrode boiler without certain knowledge to produce by hand will be difficult.

The installation process is reduced to the installation of the Galan boiler itself, attachments, strapping, connecting the electronics and pumping into the heating system of the coolant.

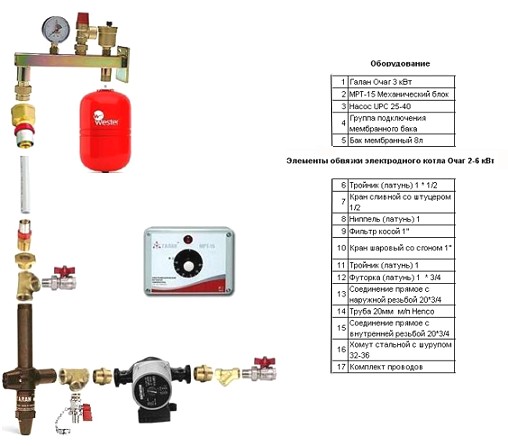

Contents of delivery

The delivery set of the electrode boiler from the manufacturer includes:

- electrode assembly with a power of 3-50 kW

- power unit including automatic circuit breaker, modular contactor and digital water temperature controller

- digital thermostat by air "climate control" unit.

Attachments (expansion tank and pump) are not included in the scope of supply, so their parameters are pre-calculated, and the equipment is purchased separately.

Requirements for the heating system

To ensure the normal functioning of the heating system, you must meet a number of requirements:

- the proposed heating system must be a two-pipe closed type with a membrane expansion tank (volume characteristics 1/10L)

- the boiler is mounted vertically, without exceeding the level of the radiators

- when tying the boiler it is recommended to observe the ratio of the boiler block diameter (Ø 32), Ø32 (1 "/ 1/4) riser, the Ø 25 mains, the radiator outlets (Ø 20).

For connection to the heating system, cast iron, aluminum and bimetallic types of radiators are recommended, as well as a register system with standard equipment and coolant capacity.

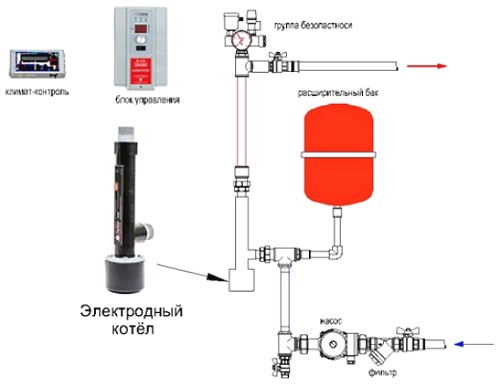

Staging of the electrode boiler

The following components of the heating system are subject to the electrode piping:

- expansion tank

- circulating pump

- security group

- return flow cranes and coarse filter

- coolant cock

- coolant drain cock from the system

- tap feeder.

Before installing and installing the electrode boiler galan, it is necessary to calculate the components of the heating system. The power of the boiler is calculated according to the area of the room and the height of the ceilings, as well as the material of the walls of the house or apartment. Then determine the location of the future installation of the boiler and develop a scheme and decoupling of the main lines, the type of radiators.

If it is planned to install the boiler in an existing heating system (in most cases), the calculation can be limited to the correct piping and the connection of the power unit and the thermostat.

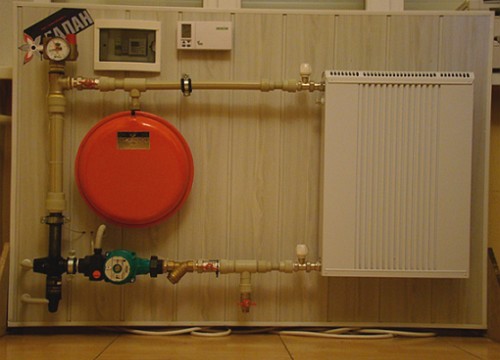

We install the Galan boiler

For the installation of the Galan boiler, use plastic pipes. In a horizontal wiring, you need to create a gradient of 3 degrees. The height of the vertical riser should be at least 2 m above the boiler. The electrode boiler requires grounding with a ground resistance of 4 ohms.

After installation of the boiler, the expansion tank and the circulation pump are placed. The stopcocks on the pipeline are installed after the return and the expansion tank. The valves are installed before and after the radiator group.

How to install the boiler and hinged standard equipment is shown here.

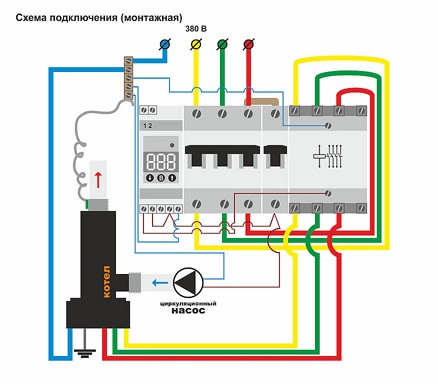

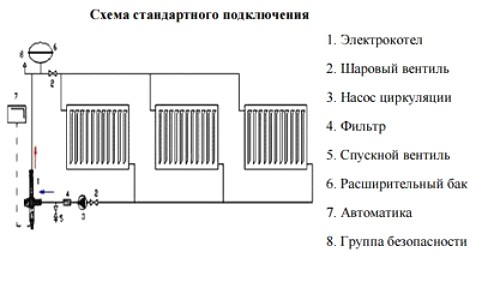

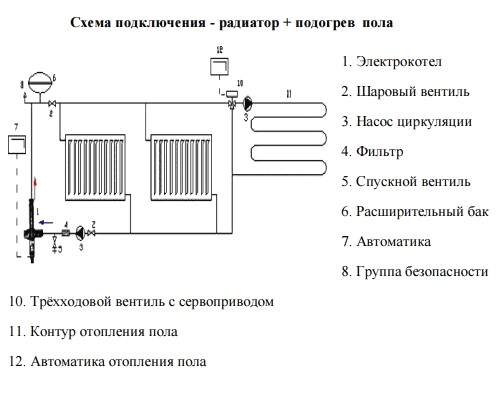

Boiler connection diagrams

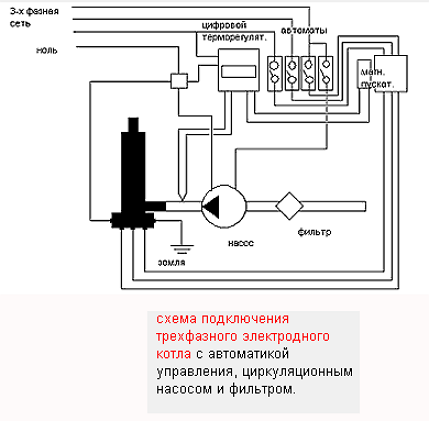

There are several schemes for connecting the boiler: basic standard, parallel connection and connection to the system of a warm floor for rated voltage 220 and 380 V and many other equally interesting schemes.

The simplest schemes are the connection of a single-phase electrode boiler or a three-phase electrode boiler with control electronics, a circulation pump and a filter. But whatever scheme you prefer to put into practice, the grounding of the installation is a prerequisite.

For example, for a gas-fired electrode boiler, center 3 with a rated input power of 3 kW, according to the basic connection scheme, a voltage of 50 Hz and a maximum boiler current of 13.7 A phases and a starting current of 5 A is necessary.

At the same time, the connection is made using a conductive copper core wire of 4 mm2 cross-section and to the heating system using a 32 mm DN clutch.

But the electrode boiler remained an ordinary boiler, if there were no control elements in the heating system with a block for measuring and adjusting the operating parameters of the CROS.

Electronic boiler control

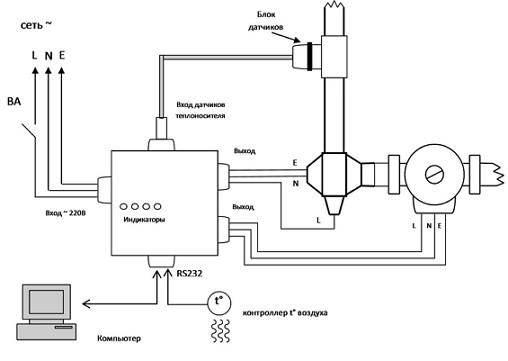

Electronic control is a device equipped with a sensor unit, a cable and an interface plug for connection to a standard RS232 interface. Schematically, the electronic control of the boiler (CROS) consists of controllers, a boiler power controller, an electronic control key for the circulation pump.

There are current controllers and coolant conductivity controllers. The current controller limits the current at the operating level set at the system start-up.

The conductivity controller performs the functions of determining the state of the coolant: it turns off the boiler when the heat carrier reaches a critical level of conductivity or continues to work. Sensors of conductivity and temperature of the carrier are remote.

For the installation of cables of the control unit, a wire with a cross-section of 0.12-2.5 mm2 is used. The ends of the cable for the control circuits are cleaned by 7-10 mm. The terminal screws loosen and install the wires. Tighten the terminals with a force of no more than 2 Nm.

Connecting the control unit will help the video.

After installation and connection to the heating system, the electrolyte is pumped in and the heating parameters are adjusted. To monitor the current in the system using hanging clamps.