A huge selection of modern fasteners allows you to securely fix or connect the necessary items. Sometimes, a layman can get lost in the assortment of fasteners: in specialized shops, the customer is provided with fasteners from the simplest plugs, dowels, screws to the most powerful bolt devices. But modern means of information allow, having studied vHF fasteners, even through the online store to purchase the necessary fasteners.

Content

Dowels and plugs for fastening

For fastening in the form of screws with a diameter of 2.7 mm. up to 6,3 mm. Appliances made of cast plastic.

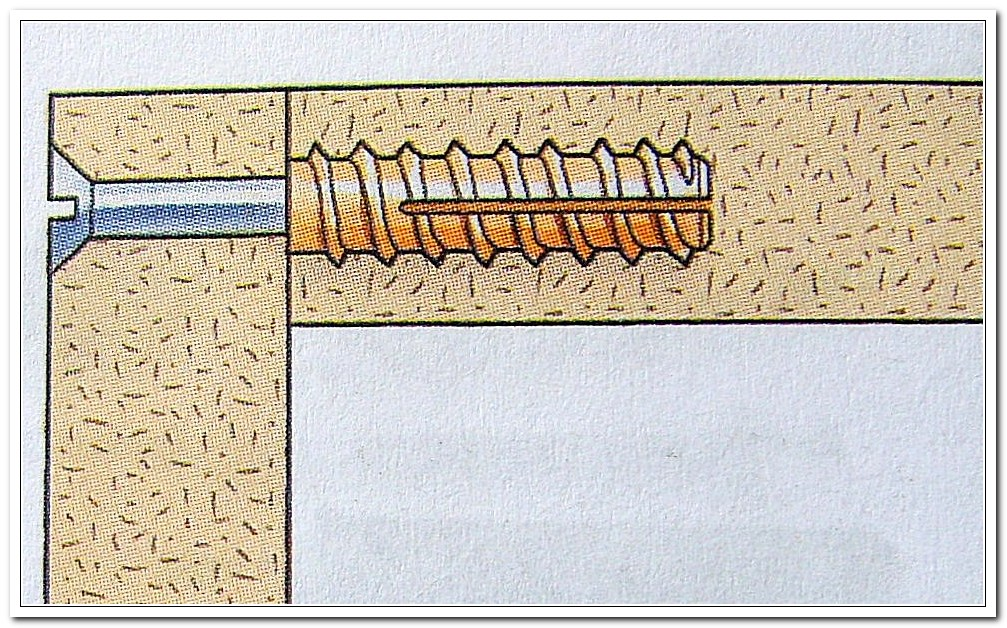

Fastening is performed by drilling holes, then a dowel or cork is inserted into this hole where the screw is screwed in.

The screw gradually expands the walls of the plug or dowel and a reliable clamp is made in the hole in the wall.

For convenient work, the dowels can be metal or plastic, they can have a coarse thread and a pointed tip.

This kind of fasteners used lightweight blocks and drywall.

Spacer bolt or anchor bolt - reliable fasteners

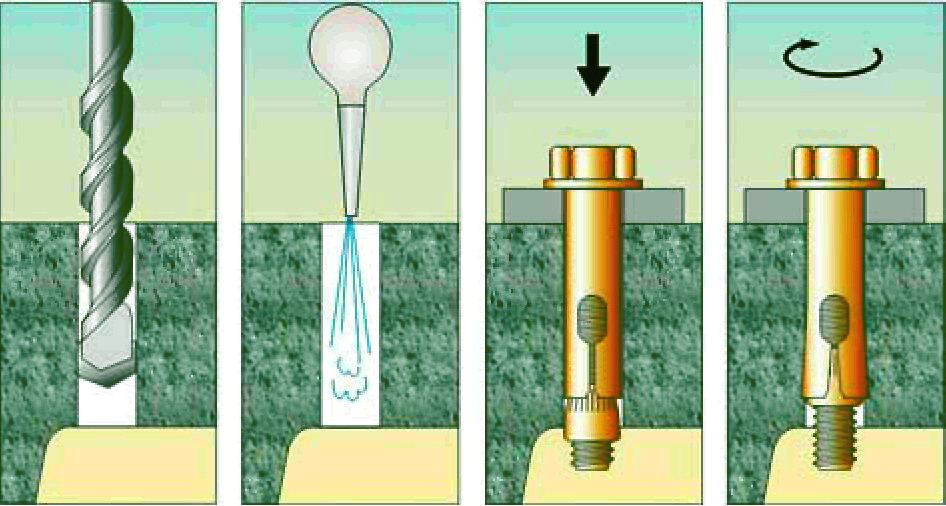

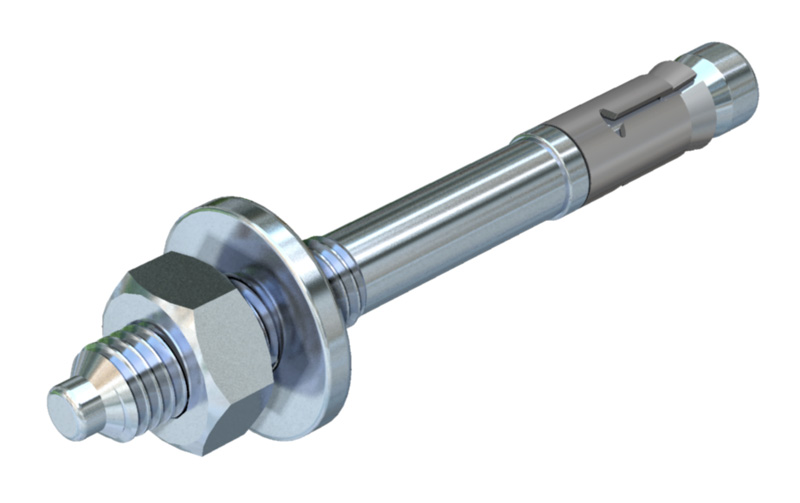

Spacer bolt or anchor bolt is used for more reliable fastening.

The principle of operation is screwing the bolt, which passes through a metal or plastic sleeve, into the thread of the extension nut.

The subsequent tightening of the bolt allows to expand the segments of the nut and clamps it into the hole.

In addition to spacer bolts, hooks and eyelets can also be purchased with the same fastening.

Dowels-nails as fasteners

Dowel-nails can be used instead of dowels with screws. There are two types of dowel-nails.

The first is made of a dowel with a flange made of pressed plastic plus a nail for masonry.

The second fastener consists of a complete set: a screw plus an anchor for clogging.

Applying such fasteners, use a hammer, as in the drilled hole fasteners are hammered, and if you need to remove the screw - turn it with a screwdriver.

This fastener is actively used for fastening frames, wall cladding, for fixing the plinth.

What fasteners are used for fixing frames

In construction, very often it is necessary to make works on fastening door and window boxes, this connection is made on screws without preliminary drilling and marking.

Long fasteners are provided with screws or bolts with galvanic coating and plastic plugs.

The box or frame to be installed is fixed in place, drilling is done in the wall, the fasteners are inserted and the screw is tightened.

What fasteners are used on frame walls

Gypsum plasterboard sheets have found wide application in modern construction, as a result we have ubiquitous gypsum plasterboard partitions.

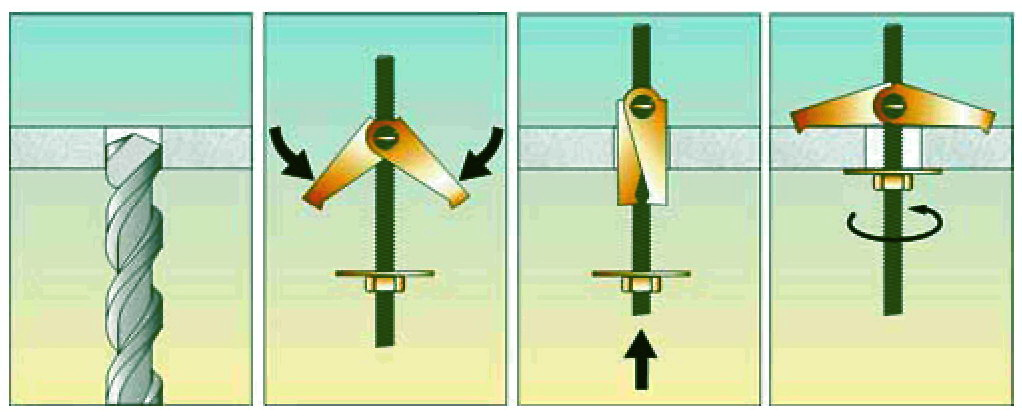

The question arises: how to produce fasteners on such walls and partitions use lever gravity and spring anchors.

Such fasteners have special levers at the end; in the inner cavity these levers are opened, under its own weight this hinge rotates at one end - this is a gravity anchoring anchor.

The spring arm anchor has two spring-loaded levers that can open when exiting behind the hole.

Further, the screw or bolt, when turned, can press these levers against the back of the panel.

But if this fasteners need to be turned out, the anchors remain in the hole and

fall into the cavity.

Such devices are not suitable for fastening large loads.

Therefore, even for medium loads, large lever gravity and spring anchors are used.

Fixing type fasteners

In life there are times when you need to save the connection by changing the type of fasteners or you need to strengthen the material.

In such cases, the collapsible type fasteners are used successfully:

- fastening for chipboard - dowel in the form of a nylon insert has an external thread. The fastener is screwed from the front or edge of the chipboard and using the screws get a reliable connection;

- a barrel-nut - if it is necessary to create a strong connection of two rails or rails to the panel, then in the blind hole (which is drilled in the crossbar) a nut-barrel is installed, in the second connection a technological hole is made, then a screw is screwed into the thread, into the thread, or bolt;

- Threaded coupling - used for concealed connection;

- nut with a flange and teeth - for a strong connection of wooden parts (the teeth of the nut clinging to the back of the hole in the parts, tightly cut into the tree);

- the connecting block or the butt block - butt block is used when connecting the panels to each other at a right angle.

The joint blocks are mainly made of plastic in two parts, each part is attached to its panel, and then joined together, since one shoe has a pin, connecting, this pin is inserted into the hole on the other half.