Do we need waterproofing for such a seemingly reliable and hermetically sealed roofing material, like metal roofing? The answer is unequivocal - yes. This need is due to the fact that during operation, the condensate is constantly formed on the inside of the metal sheet. And if there is no waterproofing layer, moisture will inevitably fall into the layer of insulation, spoiling it. In addition, moisture can also seep into the living areas. Therefore, the waterproofing of the roof under the metal tile is simply necessary. In this publication, we will consider several recommendations regarding the selection and installation of waterproofing materials for roofs under metal.

The tightness of the roof made of metal tiles is inevitably broken with time. The reason for this - the atmospheric precipitation, penetrating through the numerous gaps and crevices between the tile sheets. The roof is also permanently affected by water vapor, which rises from below, from the living quarters. To avoid unpleasant consequences of this effect, it is necessary to include a waterproofing layer in the "roofing cake". This applies to the insulated roofs, and to the "cold" ones.

Functions of waterproofing for metal roofs

Waterproofing of the roof made of metal tiles performs the following functions:

- Protects against the penetration of atmospheric precipitation.

- Protects the roof from condensation.

- Improves the thermal insulation of the roof.

The roof, covered with metal, will serve for decades, provided that the "roofing pie" is laid without breaking the technology.

In the metal roof, there are small gaps between the sheets, where a small amount of water will enter. The main task of waterproofing is to remove this moisture and prevent its accumulation. Small gaps in the roof are necessary to ensure the ventilation of the extension, thus, the service life of the wooden crate

In addition, due to air circulation, the internal and external air pressures are leveled, preventing the danger of stripping roof sheets during a strong wind.

Materials for roof waterproofing

A good waterproofing material should meet the following parameters:

- Fire safety.

- The ability to pass steam well.

- Reliability and long service life.

- Good resistance to weathering.

- Ability to maintain the original shape, not to be deformed.

- Ecological compatibility.

- The ability to effectively remove moisture from under the roof.

- Resistance to rot and mold.

Ideally, the waterproofing of the roof should last as long as the metal tile itself. Otherwise it will be necessary to repair the roof. If the waterproofing has lost its properties, then the wooden elements of the roof will inevitably deform and rot. The roof will become unreliable and will need serious repairs.

waterproofing materials: types and characteristics

The modern market offers a fairly wide range of materials for the construction of roof waterproofing. But most often for these purposes is used underlay film. It is a material consisting of three layers. The basis of it is reinforced grating, which is laminated on both sides with a polyethylene film. Actually, the film acts as a hydro-barrier, possessing simultaneously good steam-passing ability. As for waterproofing materials based on bitumen and mastic, it is not recommended to use them for metal roofing.

There are several types of film for waterproofing the roof of metal:

Normal, standard film has a dual-circuit ventilation - between the roof and waterproofing, as well as between the heater and waterproofing. Such a film is most often used for roofs of simple, "cold" construction.

Superdiffusion membrane. It has a very high coefficient of vapor permeability. When using this waterproofing material, simple single-circuit ventilation between the roofing material and the membrane itself will be sufficient. This material is easy to install, long life and resistant to mechanical damage. The only serious drawback of the membrane is a rather high price.

Antikondensatnaya film has the ability to retain a fairly large amount of water. The film itself has a slightly rough surface, but the structure of the material itself is rather dense. This material has a lot of advantages - fire safety, high resistance to ultraviolet radiation, long service life, resistance to various types of damage. However, the anti-condense film does not conduct steam very well, therefore, when using it, two-circuit ventilation is necessary. As a waterproofing for the "cold" roof, a roofing material can be used, but in this case it is necessary to create a small air gap between the roof and the waterproofing material.

When storing a waterproofing film, do not expose the material to direct sunlight. For a roof of metal, only low-combustible insulation materials should be used, which, in case of fire, will prevent the spread of the flame and will not form burning drops.

Basic recommendations for waterproofing metal roofs

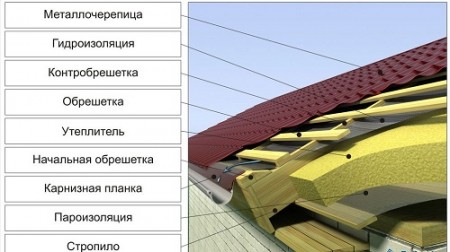

The layer of waterproofing must never come in contact with the heater, as with direct contact the material will lose its properties. The film is mounted on rafters, while the gap between the film and the roof itself should be at least 5 centimeters. This requirement does not apply to the superdiffusion membrane, since it does not require double-circuit ventilation. The film should sag slightly between the lags, it can not be tightened tightly, otherwise the films will burn to tear. It is also necessary to ensure good ventilation near the roof ridge. The overlap of the film strips should be at least 15 centimeters. If the roof has dormer windows, then lay the film in such a way that nowhere is formed a blind unventilated zone. The film is attached to the rafters with the help of special metal braces, resistant to rust. If it is necessary to isolate the places in which there are any communications - pipes, ventilation, etc., the overlapping of the sheets of film is increased, or overlapping these places with one more layer. The film is laid with a perforated layer outwards, in order to prevent water from getting under the roof.

Sequence of work on waterproofing the roof

Before the direct installation of waterproofing materials, special attention should be given to preparatory work, which includes:

- Installation of the rafter system.

- Frontal and cornice board installation.

- Installation of a gutter for the drainage system.

All the preparatory work must be done correctly, because the quality of the waterproofing depends not only on the quality of the waterproofing, but also on the reliability and durability of the entire roof.

For waterproofing works the following tools are required:

- Scissors.

- Construction roulette.

- Wooden slats.

- Stapler.

- Staples.

- A hammer.

- Drill or screwdriver.

To begin with, rafters are stuffed with a crate. For this, wooden slats are used, with a thickness of at least 5 centimeters. Roll the film rolled parallel to the cornice from the ridge down. Important point: the overlap of the film should be at least 25 centimeters if the roof has an angle of inclination of 30 degrees or less. Waterproofing is fixed to the crate with a construction stapler. But this is a temporary fastening, a permanent do with the help of wooden slats. If on the roof there are any hatches, windows, chimneys, then in these places the film is beamed on the walls of the structures.

After that, the monitor is mounted. In this case, wooden slats are used, having a thickness of at least 2 centimeters. Control grating is necessary for the secure attachment of the film to the rafter system and to ensure sufficient ventilation. When laying the film, it is necessary to make sure that the brighter side of the insert tape should lie "face" to the roofing material. Near the ridge, you need to make an air gap of about 5 centimeters. At the same time, the edge of the film must reach the gutter. Mount the waterproofing film to the protruding structures using a double-sided tape "K-2".