Choose a building fixture, buy fixtures, sometimes causes difficulty. Which class of reinforcement is preferable to choose and apply when constructing a house foundation or reinforced concrete structures? Moreover, the main and priority indicator in the selection of fittings is its price.

Content

What is an armature?

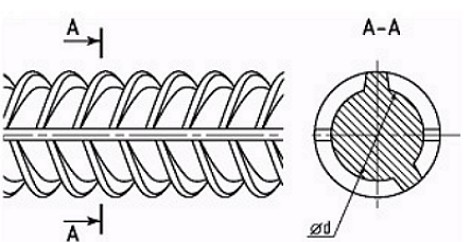

An integral part of the construction of reinforced concrete structures, which receives tensile forces, is the reinforcement. A steel rod of round shape, manufactured by the industrial method of rolling, is called building fittings.

The most common flexible steel reinforcement of reinforced concrete structures are reinforcing and welded wire rods. The scope of application and use of reinforcement is extensive, therefore, in addition to the construction, reinforcing steel is used in the manufacture of metal structures.

Rebar

Rebars designated according to State Standard 3760-98, denoted by the symbol A and conditionally divided into classes. The class of reinforcement is determined by the parameter, which is called the normalized yield strength (N / mm2).

Rebar is divided into the following types:

• Weldable (index C)

• not weldable

• resistant to corrosion cracking (K index)

• non-resistant against stress corrosion cracking

• Rolled steel for reinforced steel.

The main parameter characterizing the reinforcement is the cross-sectional area. The cross-sectional area serves as the equivalent of a round rod of nominal diameter, therefore it is necessary to use this parameter when calculating and selecting the reinforcement. Recall that the mass of reinforcement is calculated by the formula of a circle.

Technologies of industrial production of building fittings

According to the technology of industrial production, the armature is divided into:

• core

• wire.

The core construction reinforcement is made of hot-rolled steel. Rod fittings are manufactured with a diameter of 6-80 mm. and is widely used in construction.

Wire fittings are also made of rolled steel with a diameter of 3-5 mm. and is used as a reinforcing element.

Building fittings are manufactured by industry in both versions.

If the diameter of the reinforcement is small and is from 6 to 10 mm., Then rod (rod) and wire can be used. The building reinforcement of a larger diameter is produced in the form of rods having a length of 6, 9, 11.7 m. It is generally accepted that the price of building fittings is specified by the manufacturer for a ton of material.

Kinds of reinforcement of building

The core rolling stock is divided into classes:

• smooth profile (reinforcement A1)

• Periodic profile (A2 armature, A3 armature, armature A4, armature А5, armature А6).

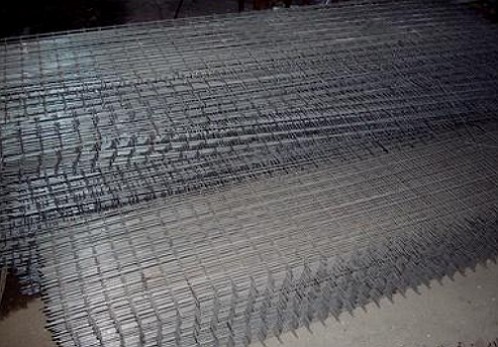

When building houses the most popular is considered the transverse and longitudinal reinforcement. Transverse reinforcement А1 (А240), longitudinal reinforcement А3 (А400С, А500С). The manufacturer of the valve can be supplied in coils (wire rod), bars or a dimensional value. The industry manufactures fittings in the form of welded nets.

Mesh reinforcement is a ready-made building material intended for deep reinforcement of foundations, slabs and walls.

When manufacturing and manufacturing valves in an industrial way, the reinforcement is subjected to hardening. By the method of strengthening the properties of reinforcement, it is divided into:

• Hot-rolled

• strengthened by thermal means.

Hot-rolled reinforcement acquires the required mechanical and physical properties due to the chemical composition of the rolled product.

The armature, which is technologically subjected to heat treatment for qualitative improvement of properties, is called thermally strengthened reinforcement.

Composite building fittings

Composite construction reinforcement is a new material and is a building fixture made of nonmetallic fibers bonded by a composite.

Synthetic non-metallic fibers have a fiberglass base, which gave a new invention - fiberglass reinforcement.

Fiberglass reinforcement has more qualitative properties:

• resistant to highly aggressive chemical environments

• does not corrode

• Has a high tensile strength

• lighter than steel reinforcement

• has a low thermal conductivity

• is an excellent dielectric

• Magnetoinert and radio transparent.

How to choose reinforcement for construction

When choosing a reinforcement for reinforcement of building structures, it is necessary to follow certain rules.

reinforcement of the foundation

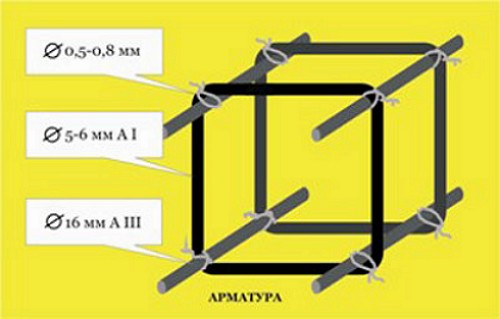

For reinforcing the foundation, use the reinforcement A1 and A3 of any diameter.

Armature class A1

Armature A1 (mounting) has a circular cross-section and a smooth surface. Due to the smooth surface has less adhesion to concrete. Armature A1 is recommended for use in parts of the foundation that experience little load. Mounting fixtures can be used to equip the reinforcing frame, for a strip foundation for lateral or vertical reinforcement.

Class A3 fittings

A distinctive feature of A3 valves is a significant cross-sectional diameter, unlike the mounting armature.

The reinforcement A3 (working) has a variable, corrugated cross-section with a ribbed surface. It is made of high-quality alloy steel with increased mechanical characteristics and corrosion resistance.

The profile of the A3 reinforcement is annular and sickle-shaped. The reinforcement, which has an annular profile, has a powerful grip with concrete. Therefore it can be used for massive reinforced concrete structures. The armature, which has a sickle-shaped profile, is more resistant to bursting loads. Therefore, it is recommended to use this type of reinforcement for thin-walled structures.

When choosing an armature, you need to imagine how it will be connected: welded or viscous.

The welding process is recommended for the fittings of non-carbon steel grades, because the weld for carbon steel is brittle.

The process of joining - the mating of reinforcement is successfully used for fittings of any class and is made by hand. The main thing is to get such magic mites for binding the armature, as shown in the video.