Metal tile is a popular roofing material. It is functional and practical. The main advantages of such a coating are: ease of installation, ease of construction, design appeal and economic benefits. In the article all types of metal tiles are examined in detail, analysis and comparison of types are presented, tips for choosing this roofing are given.

Content

General information

Metal tile, thanks to its general positive qualities, quickly took the leading place in the construction market. This universal coating can be used not only for roofing of individual cottages, it is used for any private sector facilities, or for covering small public buildings: offices, cafes, remote areas, shops.

Metal tile is a roofing material that consists of metal with a certain profile and a protective coating of various polymer materials.

In terms of its functional characteristics, the metal tile is divided according to:

- Fabrication material - warp

- Sheet Coatings

- Profile shapes and height

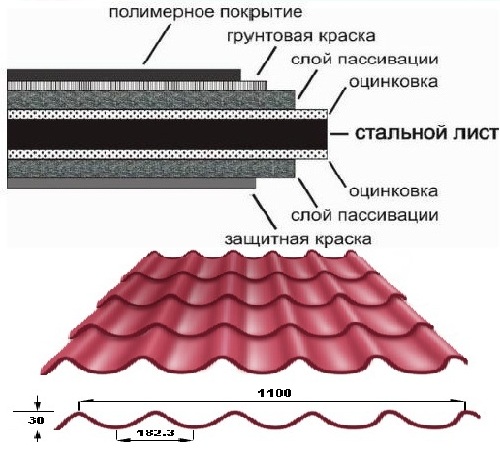

Composition of sheets of metal

For the basis of the sheet metal can be taken aluminum or steel sheet. The bulk of production is accounted for products made of steel sheets. The standard thickness of metal tiles is 0, 5 mm, but samples 0.55-0.6 mm thick are also presented.

In the second case, steel sheets have a coating of zinc or aluzinc (aluminum, silicon and zinc alloy). This increases the resistance of the roofing to adverse effects. Additionally, the sheets are covered with a protective shell of basalt chips. For example, the metal tile Gerard is made of steel sheets with aluzinc and is protected by a layer of crumbs of natural stone.

Aluminum-based sheets are lightweight, practical and durable (not corroded), but more expensive than steel sheets. In the market, such a coating is represented, for example, by the manufacturer Plannja (Sweden). Such a metal tile is not very popular among consumers because of the high cost and limitations in the color scheme.

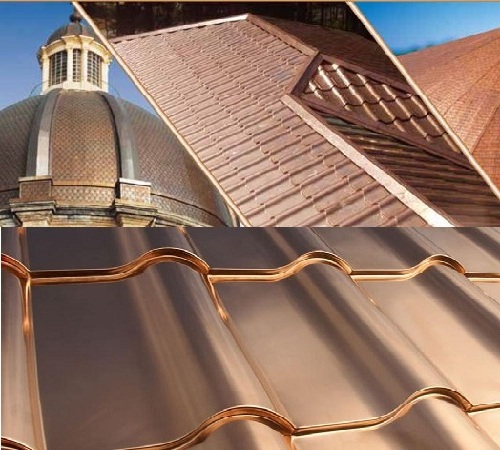

Copper tiles

A beautiful metal tile made of pressed copper sheet is produced by the Belgian firm Metrotile. This is a very practical roof covering for antiquity. It is these sheets that cover some ancient buildings and architectural forms. Copper has no cover - over time (in 12 years) the roof on the building is covered with a green patina, which is what gives the building a noble look under the old days.

Coating of steel sheets of metal tile

The practicality and durability of the roof from metal tile depends not only on the basic material, but also its protective coating is an important element. The main steel sheet is "packed" in several layers, which reliably protect it from external influences and destruction.

The sheets can be coated:

- Polyester matt or glossy

- Plastisol

- PVDF (polyvinyl fluoride)

- Terra Plegel.

The main features and differences of each of the coatings

Polyester is a fairly cheap coating sprayed on the front surface of a steel sheet of shingles. There are two subspecies of polyester spraying - glossy and matte.

Glossy (standard) polyester is a thin coating of about 25 microns. Metal tile with such a coating is cheaper, is represented in the construction market by the largest color range. A distinctive feature of this coating is the possibility of re-staining, which is not available with all other coatings. The disadvantages include increased sensitivity to mechanical damage and burnout of color.

Covering glossy polyester

Matte polyester is thicker - 35 microns. Such a coating does not have a gloss, because of what believable imitates the real ceramic tiles. Such metal tile is more resistant to corrosion and damage, color retains its freshness for a long time. The material costs on average 10% more expensive than glossy.

Plastisol over the price range is akin to a polyester coating. It is created by rolling on the steel sheet plastic films. The difference in the thickness of the layer is 200-250 microns. Such metal tiles are very popular in areas with a damp climate, since plastisol coating reliably protects the metal from corrosion. The coating is resistant to mechanical damage and low temperatures. The downside is a slight resistance to high temperatures and too active sun.

Plastisol coating

Pural is a polyurethane-based coating with the addition of polyamide. The thickness of the layer is 50 microns. Such protection is the most resistant to corrosion, perfectly withstand damage. A distinctive feature is the increased resistance to ultraviolet radiation and unfavorable weather conditions. The price of a metal tile with a pural is 35% more expensive on average than a material with a smooth polyester coating. An insignificant disadvantage is a small color scale. Apply such a coating to the manufacturers of Ruukki, Pruszynski.

It should be noted that the pural coating and mat polyester are used much less often than the protection from plastisol and standard polyester. Coatings of PVDF (polyvinyl fluoride) and Terra Plegel are also not very common in view of the high cost and special application.

The PVDF coating is very thin, but is the most stable and expensive, manufactured by the Finnish company Ruukki. Such protection does not exfoliate, can withstand high temperatures, is available in a wide range of colors. The color of the metal tile sheets under any operating conditions for a long time does not lose its brightness.

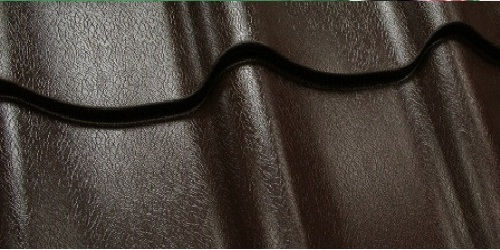

Cover Terra Plegel is able to give steel sheets of metal tiles a natural look of classic clay covering. Terra Plegel is performed by applying quartz sand to the melted plastisol. In addition, a paint coat is applied to the coating.

Cover Terra Plegele - kofe

Attention! The main average load of metal roofing per 1 m 2 is within 5 kg. Load of coated sheets Terra Plegel - 8 kg.

Metal tile: sheet dimensions and depth (height) of the profile

The depth of the steel sheet stamp affects its rigidity. The more often the relief appears, the less flexible the sheet of metal. In general, the depth of the metal tile stamp is established by the manufacturer and varies depending on the model. For example, the company Ruukkі offers Decorrey with a minimum profile height of 28 mm and Finnera - 52 mm. The most common profile height is 40-45 mm, the maximum height is 78 mm. The height of the profile is an important indicator when replacing old sheets, or laying metal roofing in certain places of the roof, where sheets with a flat profile are needed.

Manufacturers produce metal tiles with a profile thickness of 1100-1200 mm and a sheet length of 0.8 m to 8 m. Firms provide a service for cutting sheets to the required size.

Types of roofing metal. Profile form

According to the shape of the profile, the metal tile is symmetrical and asymmetric with a beveled wave. The symmetrical form is less common than the asymmetric form. On the price range and practical qualities, they do not differ.

Metal tile by type of wave is divided into several models:

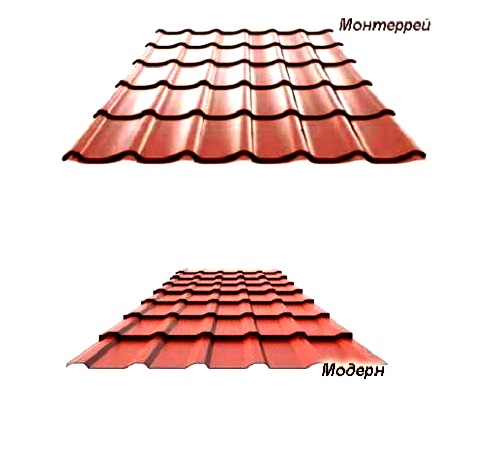

- Monterrey

- Modern

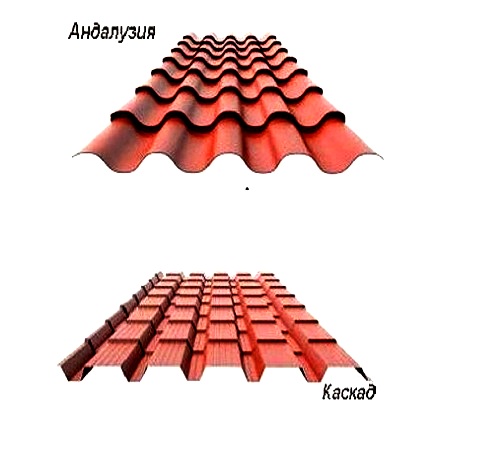

- Andalusia

- Cascade

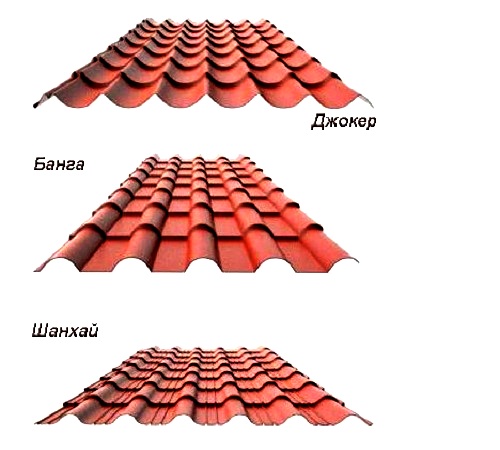

- Joker

- Banga (Banga)

- Shanghai

Monterrey

Metal Monterey is the most popular type of roofing. The form of this profile most fully repeats the classic form of ceramic tiles. Such a coating is light, it protects the roof well from the effects of the environment, practically and durably.

Modern

This roofing is a type of metal Monterrey. The main difference in angular wave forms, instead of rounded, smoothened forms. Visually, such forms differ quite strongly.

Andalusia

Such a profile has not yet received a mass distribution on the modern domestic market. The special equipment from the western manufacturers allows to make sheets of metal tiles Andalusia with the built in hidden fastening.

Cascade

The second most popular type of metal profile. Its shape looks like a chocolate bar. Such a rectilinear roof covering has a large installation width, which sets it apart as the most economical coating. Metal cascade Cascade is convenient for installation of complex roof structures. Such buildings have strict proportional geometric shapes. There are several types of Cascade profile that differ in wave height and leaf width.

Joker

This type of metal is made in the classical style. The smooth wave with rounded contours looks beautiful and really resembles waves.

Banga

Brand new, elite profile look. The quaint and unusual shape geometry gives a unique look to the roofing. Banga has a high profile wave, but a small installation width. Because of the unusual shape, a beautiful visual effect of the convexity and grandeur of the roof is created. Therefore, such a metal tile is very suitable for tall large cottages and buildings, where the beauty of the shape of the profile can be fully disclosed.

Shanghai

This is a symmetrical profile in the oriental style, received its name, thanks to the country from which he "came." Sheet metal tile Shanghai have a low wave, in the hollow there is an additional decoration stripes.

How to choose metal roofing

The basic parameters when choosing a roofing cover are the shape of the sheet, the type of polymer coating and the thickness of the material. Also important are the parameters of the roof frame (rafter system), mounted under the metal roof.

The color of the metal can be any, but it is desirable that it corresponds to the overall design idea of the entire site on which the house is located.

The type of polymer coating is selected depending on the intensity of adverse environmental effects. If the living area does not have a strong scorching sun, and the winter is mild, then the usual polyester coating is chosen, which will save on costs, but the material will serve for a long time without damage.

When buying metal, you should ask about all parameters in detail and see the quality certificate. The guarantee for such roofing material is on average 10 years. It is given on the polymer coating. The actual service life of a properly selected metal tile reaches 50 years, subject to all requirements for installation and operation.