Everyone knows that the beginning of the theater is a hanger. There is a similar statement about the beginning of the infield - it's a gate. The functions assigned to it have many meanings: protection of the land area from intrusion of strangers, visual beauty, harmonious connection with the general design of the site. It will be wonderful if all the above qualities of the wicket are added, and strength, reliability, lack of deformation and changes in its qualities under the influence of bright sunlight, severe frost, torrential rains, as well as the possibility, if desired, of replacing the lock. All requirements are met by a wicket gate made of corrugated board, installed on a metal structure.

Content

Wicket for fence from corrugated board

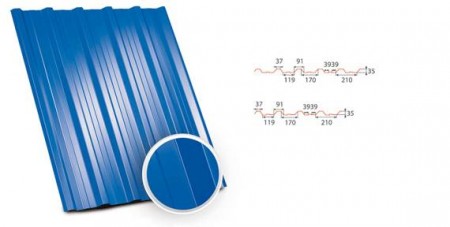

Profiled sheeting is a metal sheet, which under the pressure of a stamp of a certain type takes the form of a profile. Sheets of corrugated board are different in size and shape. From these characteristics directly depends the area in which this sheet is usually used and the strength of the structure from it. For the organization of vertically arranged structures it is customary to use sheets of grades С-8, С-10, С-20. In this marking, the letter means the specificity of the assignment, and the figures indicate the wave height in millimeters.

Sheets of corrugated sheet are produced in two types: painted with polymer paint or galvanized. Polymer coated sheets have higher performance. In the production process, they are applied two protective layers - zinc (it protects the metal from oxidation) and paint. Accordingly, the cost of this sheet is an order of magnitude higher than that of galvanized steel. If desired, such sheets can be painted with a special paint produced from powder.

In addition to a long service life, there are other advantages. The weight of such sheets is not large, about 5 kg per 1 sq. Km. This plus greatly facilitates the process of mounting. Correct the size of the sheet to the desired can be done with ordinary scissors for metal. Experts advise not to use for cutting with a Bulgarian, as the high temperature in any case will damage the applied paint. Fastening of profiled sheets is performed by special screws.

Wicket door fence

To start working, you need to create a drawing in which the height and width of the wicket in the fence will be calculated, and the required amount of consumables is calculated. Different firms-manufacturers produce a corrugated board of unequal width. The average width is 1 meter. The height of the building stores is regulated at the request of the customer. By ordering the corrugated sheet according to the exact dimensions in accordance with the drawing, the buyer receives the material, the ends of which are painted with paint. This layer significantly improves the anti-corrosion properties of the material.

For the construction of the frame will need square pipes of 20-25 mm. The structure of the frame directly depends on the shape of the desired wicket. When creating a drawing, it is necessary to take into account the pipe dimensions. In order to prevent skewing, you need to make ribs that will give more rigidity. Make ribs of thinner tubes than those used to arrange the frame. The pillars for the support and fastening of the hinges are most often made from square pipes, but if desired, another similar metal can be used. It must be remembered that one edge of each of the supporting pipes will be deepened into the ground approximately 1 meter and concreted. Also, to mount the wicket, you will need:

- self-tapping screws for fixing corrugated board,

- handle and lock,

- loops.

What is needed for the construction of the wicket from the corrugated board

Required Tools:

- screwdriver

- welding machine

- sander

- roulette

- level

- bulgarian.

Additional materials:

- rests of roofing material

- a small amount of bitumen mastic,

- paint for metal

- concrete or cement-sand mortar,

- primer with anti-corrosion properties.

In specialized stores, you can buy a paint can of 100% corresponding to the tone of the purchased sheet of corrugated sheet. It may be needed directly during the mounting process or in the future when scratching occurs.

How to install a wicket from a corrugated board

installation of support pipes

After the drawing is created and all the necessary materials are purchased, you can start the work safely. The process begins with the mounting of supports. This moment is very significant. From its quality performance depends the ease and ease of opening the gate.

Preparation of supports is as follows:

- with the help of a grinder, the legs of a certain length, indicated in the drawing, are cut;

- if necessary, they are cleaned of rust and scale;

- paint with a coat of primer and allow time to dry.

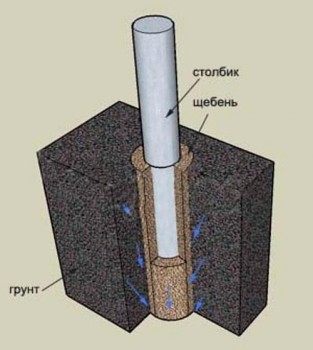

While the supports are drying out, it's time to start preparing the pits for the pipes. Dig them down about a meter deep and wide, 20 cm wider than the diameter of the selected pipe. The distance between the supports should be 2 cm more than the width of the wicket. At the bottom of the pit it is necessary to put the non-format of the ruberoid and gravel. The edge, which is planned to be concretered, must be coated with mastic, then immersed in a pit, using a plumb and level to properly locate the support and pour it with concrete solution.

how to install a wicket and frame for it

It will be most convenient to make a skeleton of square pipes. Cut out the design with a grinder, according to the previously known dimensions from the drawing. Then measure all the dimensions. Between the frame and the gate there should be a gap of at least 1 cm. This distance will prevent galling. At a gate of the rectangular form it is necessary to compare diagonals - they necessarily should be identical. The pipes are welded, the welding site is cleaned by the Bulgarian, sanded with sandpaper and primed. Now you need to determine the location of the lock and the handle. It will be most reliable at a certain height to weld a pair of iron bars, to which it will be possible to attach a handle and a lock.

wicket in the fence of corrugated board - painting and mounting of the profiled sheet

Staining of the support and frame is initially made in one layer. After a certain time, when the paint has dried, a sheet of corrugated sheet is fastened to the frame by special screws. With fasteners you need to use the level. Immediately, the sheet is attached only by two screws that are diagonally spaced from each other. Use the level to check the correct position of the sheet in a closed and open state. If everything is smooth, then you can screw in the remaining screws, at least 6 pieces per 1 sq. M. m.

how to make a wicket in the fence - installing a lock

The location of the lock is determined during the welding work of the frame. Attaching the lock to the frame, on the proflist mark the place for the proposed lock well, and draw out the outline of the hole in the support. Cut the hole in the support by the bulgarian. From sharp edges get rid by means of a file. Using a pair of metal scissors, a hole is cut in the profiled sheeting.

A wicket made of corrugated board, according to all norms and rules, will last a fairly long period of time:

- the material used for the wicket described does not react at all to atmospheric phenomena,

- she looks pretty decent,

- if necessary or desired at any time can be replaced by a similar one.