The question of how to dig a well arises from the owners of a suburban area immediately after its acquisition. Today, there are several options for the extraction of drinking or technical water, the rationality of the application of one or another option is determined by the geological features of the terrain, the depth at which the aquifers lie, the financial possibilities of the owners. If the depth of the aquifer is very low, then it becomes necessary to drill a well. See here first of all on the choice of location for the well, the place must comply with all sanitary standards, determine the executor, with the materials, discuss the price and go ahead. If the water is shallow - dig a well, and we'll show you how!

Content

- 1 Types of wells found in suburban areas

- 2 How does the pit work?

- 3 Kopka wells with their own hands

- 4 How to dig a mine and make a log house for a well with your own hands

- 5 Construction of concrete wells

- 6 Well of natural stone

- 7 Where to dig a well and when to start work

- 8 How to build a house for a well with your own hands

Types of wells found in suburban areas

By digging a well is usually resorted even if the water supply system of the dacha is connected to a centralized water supply system - paying bills for water for irrigation is not a cheap pleasure. In addition, the water from its own well is much more delicious, it is more pleasant to use for drinking and cooking. Digging a well on a site means to protect yourself from water supply disruptions that happen at the most inopportune moment.

Among the most common types of wells are:

- the cheapest tubular, or bore - on sand, Abyssinian, more expensive - artesian,

- pipe systems,

- top-down and bottom-up key,

- mine.

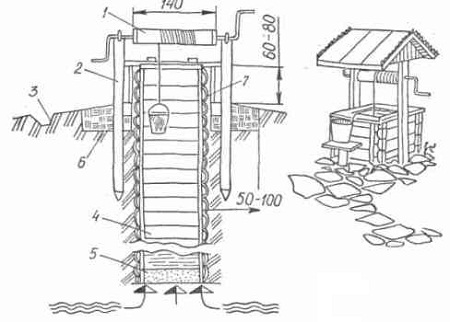

More often there are shaft wells, for which the optimal ratio of cost, complexity of construction, quantity and quality of water is typical. There is such a well from:

- head, located in the upper, ground part,

- the main trunk, which is the longest part of the structure,

- buzzer, or water intake - the lower part, which serves for the accumulation of liquid.

How does the pit work?

The purpose of the upper part of the well is to protect water from getting debris and dust, rainwater, for the same purpose, a tightly fitting lid of water-resistant material is selected to the headband. Also, the head should warn the freezing of the well in the event of severe frost.

The main shaft of the well is different, depending on the material of its structure. Optimum is considered round, but for a wooden frame a square is often used, it is also found hexagonal.

The depth of the well of the well is calculated based on the planned water consumption per day. If the rate of water supply to the well is large, then 1 m is considered sufficient for the water intake, but if the grounds are shallow, then the area of its placement is transferred to the maximum permissible depth. The drawing of the well, in particular the calculation of its depth, is carried out in accordance with the availability of groundwater in the area where the construction is planned.

Kopka wells with their own hands

The most important condition for successful digging of the well is not very deep occurrence of aquifers. This place should also not be located near the sheds, which contain large livestock, toilets, places for the accumulation of manure. If the site is not observed excessive dryness, then choose a place on the hill - it will significantly reduce the threat of water pollution in the well. From the economic point of view, the well should be located closer to the place where water is consumed - thus, it will be possible to minimize the cost of transporting the liquid. The minimum distance from the house to the well should be 5 m.

Before digging a well, one should realize that this task is not simple. The construction of the shaft is carried out in two stages:

- first digging a mine,

- then it is strengthened.

Digging a well is easier in dense soils, although sometimes this factor becomes an insurmountable obstacle in work. The depth of the mine and the method of strengthening its walls depend on the qualities of the soil. Work can be done using special construction equipment or manually.

At performance of work for a minute it is not necessary to forget about safety rules:

- The bucket, by means of which the ground will be removed outside, must be securely fastened to a strong rope, its lifting should be done carefully.

- The person who will work at the bottom of the mine will definitely need to wear a protective helmet.

How to dig a mine and make a log house for a well with your own hands

After the completion of digging the shaft, the bottom of the well is leveled, the incoming water is pumped out. The construction of the wooden frame begins with the assembly of the thickest logs. In the event that the ground is not strong enough for the first logs stack large stones. When installing the first crown, you must strictly monitor its horizontal position. Then the rest of the crowns are successively stacked, so that they fit as tightly as possible into the pressing with a wooden hammer. The seams between the crowns are covered with clay. After installing the wreaths, the bottom of the well is covered with a layer of gravel and sand. To prevent skewing skew in its inner corners fill thick boards.

The influx of fresh air into the well is ensured by installing a vent pipe. If the soils on the site of construction of the well are shallow, it is recommended that the lower part of the frame be built according to the principle of the tent. If the estimated depth of the well is of the order of 40 m, then the method of building a log-house is used by building up from above as the soil is sampled. In order to move the log house more smoothly, its lower frame should have sharpened edges, sometimes they are made of steel, the process of lowering occurs due to the inherent severity of the wood. To achieve a uniform lowering of the frame, first dig a hole, install a frame, then undermine under it the ground.

Construction of concrete wells

Concrete wells can be:

- made of plates or rings,

- monolithic.

The construction of a monolithic well is to dig a mine with subsequent installation of formwork and concreting. If the depth of the mine is small, the concrete is poured directly into the mine itself, a double formwork is being built to fill it.

With a large depth of the mine, a descending method is used, i.e. The concrete is concreted to a shallow depth, the formwork is removed above the level of the surrounding soil. On the lower part of the concrete shaft a special shoe with a knife is mounted, which makes it possible to perform a uniform draft.

For the manufacture of concrete it is recommended to use only high-quality Portland cement, if using a poor-quality material, the trunk may eventually break down and cause severe water pollution.

Concrete mixture is manufactured in such proportions:

- 2 parts of sand,

- 1 part of cement,

- 3 pieces of rubble or gravel.

The obligatory moment is the use of high-quality steel rods without rusty stains as armature - they will prevent cracking of concrete and increase its stability.

It is much easier to use ready-made concrete rings for a well. Since it is required to achieve the greatest possible fit between the rings, then for their connection, steel Z-staples are used. Even better, if the purchased rings will be equipped with a special locksmith, allowing for high-quality docking.

Begins digging wells from digging holes, corresponding to the diameter of the concrete ring. When the pit reaches a meter depth, the first ring is inserted into it and continues to deepen. Next, the next ring is installed.

The self-construction of the well involves the participation of at least three people: the first is engaged in digging the mine, the other two are extracting soil from it. Digging pits continue until the aquifers are reached. Their decrease will be indicated by a drop in soil temperature and the appearance of small fontanelles. This method of equipping a mine well is considered less secure than the simultaneous dropping of all rings into a fully excavated mine - the risk of collapse of the ground is significantly reduced.

If in the process of work it turns out that the rings will stop lowering independently, then it will be necessary to take measures for their alignment along the vertical. Eliminate the problem by laying a wooden guard on top of the rings and loading it from above with bags of sand. The rings, which are under such a load, will equalize after some time and the work can be continued.

If there is a possibility to move the rings, use a winch or a crane.

Since at the bottom of the well it is necessary to equip the filtration system, after reaching the required depth, continue to deepen the shaft for another 20-25 cm, then clean and level the bottom, fill with a layer of sand and gravel that will provide natural filtration of the incoming water. Then all the water that has accumulated in the well is pumped out.

Use accumulating liquid for cooking immediately is not recommended - it is suitable only for watering beds or other household needs. After a certain time, water is taken for analysis to confirm its quality. Only in case of a positive result, water can be considered drinking.

The well of concrete plates is very similar in assembly to a wooden one. The weight of each plate is 35 kg, they are assembled using a conventional solution. To give strength to the structure, its corners are reinforced by welding.

The construction of a well in the heaving ground threatens to push out the upper rings during the onset of severe frosts. To prevent this extremely undesirable phenomenon, a thick polyethylene is laid between the soil layer and the rings. When moving, the ground will slide along the film, and the rings will remain stationary.

Well of natural stone

Quite rare are wells, whose mine is lined with natural stone. The most suitable form for such structures is the round one. As a material, sandstones, shales, limestone are used. The existing material is sorted by size, the masonry is made from approximately identical fragments, to a cement slurry. The space formed behind the walls of the well mine is covered with crushed stone. To lay stones is recommended by a narrow part inside - this will prevent the possibility of extruding fragments from the finished wall.

Sometimes a well-burnt red brick is used to build the walls of the well.

Where to dig a well and when to start work

It is believed that a rational option would be to dig a well with a depth of up to 30 m, deeper wells are too expensive, and if they need maintenance, owners will face many problems.

Having studied the material on the varieties of water sources, having decided on the appropriate type and drawing the well, another important question should be solved: how to determine the location for its placement. To do this, you can use different methods, for example to seek help from the Hydrogeology Service. But it should be noted that the information may not be particularly optimistic - hydrogeologists can not always reliably determine the presence of water-bearing veins in low-water clay soils.

There is also another, rather surprising method, which has been used since ancient times - biolocation. Although he does not find any scientific confirmation, but the predictions about the presence of water and the depth of its occurrence are almost always correct.

In practice, often use the method of interviewing neighbors - if in nearby areas wells have the same water level, then you can safely dig a well on the line connecting neighboring sources. Sometimes such aquifers occupy several hectares. Much more difficult to determine the place in the event that near, in a radius of 200-300 m, there are no wells or wells at all. In this case it is necessary to resort to drilling test wells - this is the only way to obtain reliable information about the occurrence of aquifers.

As for the time to start work, it is best to start them at a time when the moon is in signs of the water element, especially in Pisces. To the same, the Moon must be growing. The choice of time should also be taken into account the seasonal level of groundwater (preferably the lowest). The most successful may be the end of summer-early autumn, before the fall of autumn. It is also possible to build a well at the end of winter, but before the snow melts, however, during this period problems may arise with the deep frozen ground.

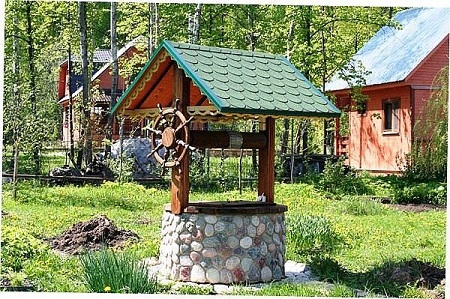

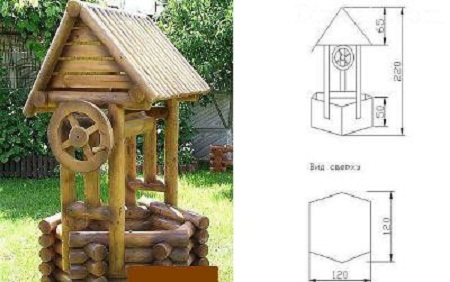

How to build a house for a well with your own hands

The original house, created to shelter the well, must protect the water from getting into it debris and fallen leaves, dust. At the same time, the attractive design of the house can make it a real decoration of the country plot. For construction, you can use any materials, including slate and roofing iron residues, corrugated board, rounded log or beam, metal pipes, forged or cast metal structures, metal roofing. When drawing up a project, it is necessary to take into account the style of other structures on the site and the materials from which they are made.

The area around the well should be covered with rubble. On the tightly compacted layer of it, the frame of the house is set. The construction of the building can be developed independently or use a ready-made drawing with calculations. Usually there is a canopy over the well - a gable roof. Having installed its frame make the gate, even if the water is extracted by a pump. A bucket will be attached to the gate using a chain. Next, it remains to build a crate on the roof frame and lay the selected roofing material.