At present, when choosing a project of a building, many prefer the brick and concrete houses, which are customary for our country, which are much less expensive and, moreover, quite quickly built. There is a so-called Canadian building technology using SIP panels. The houses built using this technology cost a little more than the frame, they are built very quickly and have a number of advantages. Due to their positive qualities, SIP-homes find a significant number of fans among people of the most diverse level of prosperity.

Content

- 1 What is a SIP panel

- 2 Physical properties of SIP panels

- 3 Problems in the construction and operation of SIP houses

- 4 The positive and negative aspects of SIP construction

- 4.1 dignity:

- 4.2 limitations:

- 5 Production technology of SIP panels

- 6 How to build a house from SIP panels (a step-by-step course of work)

- 7 Construction of a CIP panel, reviews of home owners

- 8 Selection of SIP panels

What is a SIP panel

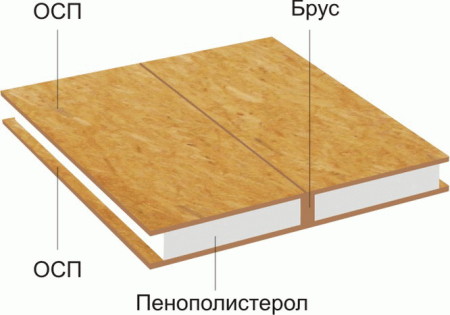

SIP - "Structural Insulated Panel", from English translates as "structural insulating panel", abbreviated - SIP. The SIP panel is a building material obtained by gluing with glue on the basis of polyurethane of two OSB slabs (oriented chipboards, in English - OSB) and a layer of expanded polystyrene between plates with subsequent exposure to high pressure.

SIP panels are widely used in modern construction, because they have high mechanical strength and resistance to environmental influences. This technology is known in the world for nearly seventy years, in 2003, with the assistance of the Canadian corporation in Russia, the first plant for the production of SIP panels was built, since that time their production has been constantly increasing and the technology is called "Canadian".

If the woodworking industry waste is most often used for the production of chipboards, the basis of the OSB is split high-quality wood, laid with layers with alternating transverse and longitudinal orientations and pressed in the form of a plate with the addition of resins and wax. The production uses chips from 60 to 140 mm in length. They are stacked in three layers in the "pie". In fact, OSB is an improved wood that has moisture resistance, increased elasticity, improved properties to keep fasteners. In the production of OSB sheets, coniferous wood is used, but there have been cases of purchases in China of OSB from poplar, the wood of which has the worst performance characteristics.

The OSB sheets are mostly made of wood, therefore they are environmentally friendly materials, they are easily processed and ground. They can be used not only for the production of sandwich panels, but also used in wireframe housing, used as a lining under the roof, to arrange internal partitions in the building, etc. For the production of self-supporting insulated panels, a OSB-3 plate is used. Marking "3" means that this sheet of OSB has an increased bearing capacity, is moisture-resistant, for which a wax is added to the structure of the panel, giving the panel additional protection from harmful environmental effects.

As a layer in the production of panels used expanded polystyrene - gas-filled heat, soundproof material. Styrofoam has high energy-saving properties, low water absorption and vapor permeability. Due to the low coefficient of thermal conductivity of 0.12 m of this material it retains heat in the same way as a layer of wood 0.5 m thick, foam concrete thickness 0.9 m or brick thickness 2.4 m.

Unmodified polystyrene foam is a flammable material with increased flammability, therefore, in order to reduce fire risk, Russian standards permit the use in construction of only materials with flame retardant additives that provide self-extinguishing and inability to support self-combustion of the material.

Expanded polystyrene is a durable material, studies have shown that the service life of expanded polystyrene is at least 60-80 years.

Physical properties of SIP panels

Despite the fact that the CIP panels are made of chipboards and a lightweight porous material, they are flexible and at the same time fairly strong. OSP-plate is bent under the influence of a large load, and polystyrene foam can not be considered strong at all, but the resulting composite construction material from bonded sheets of OSB and expanded polystyrene has acquired new mechanical characteristics that significantly exceed the properties of its constituent parts. SIP-homes are able to withstand significant wind loads and earthquakes. The panels are able to bend, but, without breaking, to withstand transverse loads of up to 650 kg / m 2. This value is 1.5-2 times higher than the loads held by reinforced concrete slabs. In the longitudinal direction, the panel is able to withstand about 10 tons per 1 running meter, which is sufficient for low-rise construction of SIP panels.

Along with great strength, low thermal conductivity of structures made of self-supporting panels is also their important feature. The lower the thermal conductivity, the less heat is needed to heat the building. According to the thermal efficiency, wooden houses or brick ones with insulation are inferior to SIP-houses in 6-8 times.

The small weight of panels plays a huge role. Weight of one square meter. m brick wall with a thickness of only 0.25 m exceeds 20 times the weight of the wall from a SIP panel with a thickness of 174 mm of the same area. The weight of one panel of the most used for building houses ranges from 40 to 70 kg, so there is no need to use machinery, which is especially valuable if there are no entrances to the site on which construction is performed. The building can be installed on a light foundation, thereby reducing the time of construction of the house and the total cost of construction.

Problems in the construction and operation of SIP houses

The construction of buildings from SIP panels is the most controversial: some support this technology, others are ardent opponents of it. The fact is that in Russia it appeared only 14 years ago, therefore it did not receive a general recognition, although it is widespread all over the world. However, it should be noted that the number of people wishing to have such a house is constantly increasing. This is primarily due to the merits and relatively low cost of the house. The construction of the building is simple, but with the use of quality materials and observance of the manufacturing technology, you can get a reliable, warm, inexpensive and durable house. The estimated service life of the building is more than 80 years.

Any technology has its drawbacks and SIP technology is no exception, so you need to know the weak points to understand how to get rid of them.

environmental friendliness

Since CIP panels are relatively new construction materials in Russia, data on their environmental friendliness are not enough. This enables the opponents of SIP construction to argue that the main material from which the house is made, in particular, OSB-boards and expanded polystyrene, poses a threat to human health. In the US, Canada and European countries, where CIP panels have been used for more than a decade, research has shown their harmlessness and the possibility of application, including in housing construction.

OSB-board has in its composition 90% of wood, bound with natural resins, fillers, hardeners, synthetic wax and boric acid salt. These substances in the plate do not emit dangerous substances. Styrofoam from which the heat-insulating layer is made, under normal conditions of use, is also considered a harmless substance and its direct contact with food is allowed.

ventilation

It is generally believed that the CIP house is not "breathing", since there is no fresh air intake due to its tightness. On the one hand this is an advantage, since heat losses are minimal, and on the other hand there is a drawback, because a person needs oxygen inflow and removal of excess moisture, which is formed with exhaled air, during cooking and when taking a bath or shower. Excess moisture should be removed, as in a warm room it promotes the multiplication of pathogens, so the CIP-house needs good ventilation. To do this, it will be enough conventional straight-flow natural ventilation. Therefore, when the building is being built and the roof is being laid, it is necessary to make at least two ventilation penetrations: in the kitchen and in the bathroom, thereby creating a ventilation duct that will draw the polluted air outwards. The length of the canal about 3-4 meters is sufficient to create a good traction.

But there will be no normal thrust if there is no air supply. It can be solved in different ways, but in a house where fiberglass windows are installed and people permanently reside, it is better to install inlet valves. They are put in "clean" rooms, for example, in the bedroom, living room. As a result, clean air from the street goes into the bedroom, passes through all the rooms, is sucked out of the bathrooms and kitchens without any electric fans and is thrown back onto the street. Having a very warm box at home, you can neglect the loss of heat due to ventilation. To save heat, you can use a recovery system, but it will require additional costs and can pay off only after a very considerable time.

fire resistance

SIP-house is subject to burning, however, in the event of a fire, all houses are burned. After a fire, only houses made of aerated concrete are restored, the rest, even brick ones, are subject to dismantling. Therefore, the main task is to prevent the occurrence of a fire. SIP-buildings correspond to the third degree of fire resistance. The flame retardant, which is a part of the panel, makes its burning impossible and keeps the fire within an hour. Styrofoam is not flammable, however, if it is in the fire zone, it will burn completely, but it will produce much less energy compared to wood. By the amount of heat and toxic substances released during combustion, the CIP panel is in a more favorable position than the wood, since this value is several times less. Good sealing prevents the spread of smoke and fire in the house. Exceptional styrene is very dangerous for humans, but in case of burning, even with a non-hazardous concentration, there is a strong specific smell, which should be a signal for immediate evacuation and call the fire brigade.

Often, building errors lead to fires, and there are two main reasons for their occurrence: a poorly made chimney and improperly constructed electrical wiring. When designing a building, it is necessary to take into account the places of installation of fireplaces, stoves and carry such combustible structures as walls, logs, ceilings, roofing, rafters to safe distances.

A modern house is unthinkable without electricity and a qualitatively designed wiring is a guarantee of its long-term trouble-free operation. Some builders burn in the layer of expanded polystyrene channels for the subsequent laying of electrical wiring in them. In this case, the integrity of the panel is violated, the requirements for installing wiring inside combustible structures in the metal hose are not observed, and the risk of fire if it is damaged increases. In addition, it is technically very difficult at the same time to install SIP panels and perform electrical wiring, so in such homes, electrical wiring is usually laid in the finish layer.

soundproofing

All light houses, including SIP houses, have inadequate sound insulation. To extinguish sound waves, the material of the house must either be heavy, or have a high viscosity. SIP-house has a reliable, rigid and at the same time light construction, so the sound that occurs in any room will spread along the wooden frame.

One of the inexpensive ways to improve sound insulation is a patch on the inside of the SIP panel of expanded polyethylene with a thickness of 8 mm, on top of which a gypsum board system is mounted. Due to the layer of polyethylene, the impact of the sound wave on the frame of the building will be greatly reduced.

For floors, a soft layer of foamed polyethylene is not applicable, so a wood fiber board with a thickness of about 7 mm can be used, laid on a CIP overlay plate under a layer of a laminate, bag or other floor covering.

defeat of SIP-houses with rodents

There is a firm belief that SIP-houses are a favorite habitat for rodents, but the practice of building houses for many years has been refuted. It is believed that for some reason the structure of the CIP panel, unlike mineral wool, is not suitable for housing accommodation for rats and mice. However, it is still necessary to take measures to block the access of rodents to the house: fill the ground under the house with fine gravel, remove cracks, close the ventilation holes, equip the entrance doors with door closers or springs. In addition, to eliminate the possibility of the appearance of rodents in the house, it is possible to lay a metal fine-mesh net along the perimeter of the 1st floor from the outside of the building.

The positive and negative aspects of SIP construction

Summarizing the review of the characteristics of houses from SIP panels, we can note the following advantages and disadvantages.

dignity:

- high speed of construction;

- there is no need to use heavy equipment to transport materials and erect a building;

- relative ease of erection of the building;

- simplicity in the finish, as with the installation of all the walls, the floors and the roof are perfectly flat;

- relatively small weight of the building, and, as a consequence, no need to use an expensive heavy foundation;

- the possibility of year-round construction due to minimal shrinkage of the foundation;

- very good thermal insulation of the building, thus saving money for heating and air conditioning;

- increase the useful area of the house by reducing the thickness of the walls.

limitations:

- the need for home equipment with reliable ventilation;

- less strength of the structure in comparison with buildings made of bricks or timber;

- b abouta higher fire hazard compared to brick buildings, inherent in all structures of wood;

- because of the low heat capacity of materials, air in the rooms quickly heats up, but also cools down quickly;

- insufficient soundproofing;

- low security of external walls from the actions of intruders;

- the allocation of polystyrene with toxic substances in the event of a fire.

Production technology of SIP panels

The line of factory production of SIP panels can be divided into the following sections according to their purpose:

- the assembly table on which the "pie" of the sandwich panel is formed;

- applicator;

- press;

- a cutting table;

- table of unloading products.

The gluing machine is applied evenly, without voids, with even, thin streams of glue. To polymerize the glue, water is sprayed, due to which the glue reacts. Further, the slabs are sent to a 20-ton press and are compressed under pressure, thereby the glue is distributed more evenly over the surface and penetrates into the expanded polystyrene structure, which can later be seen on the panel cut. To obtain a quality adhesive bond, the panels remain under pressure for a certain time, and the full polymerization of the adhesive occurs at least 24 hours later.

The panel does not require additional wind and moisture insulation and is fully suitable for further installation.

How to build a house from SIP panels (a step-by-step course of work)

When choosing a building project, it should be taken into account that it is more profitable to build a two-storey building, for example, with a mansard roof, since the dimensions of the foundation and the roof are the same for both options, only the amount of materials that go to walls and ceilings varies. But, on the other hand, it is necessary to take into account that due to the need for the device of the staircase a considerable part of the useful area is lost.

If there is no need for basement equipment or the type of soil does not allow the construction of a different foundation, the pile foundation is ideally suited for a house made of self-supporting panels. Most often, the foundation is applied to screw piles located at a distance, usually about 2 m from each other, on top of which the strapping from the bar is installed. The pile-screw foundation is mounted for one day and does not shrink.

To assemble a box of quality SIP-house, the following basic materials are needed:

- CIP panels;

- planed beams;

- planed boards;

- mounting foam;

- sheet or roll expanded polyethylene;

- metal fasteners: long and short screws, nails.

On the harness is laid overlap of the SIP panels, which is the floor of the first floor and is screwed to the strapping with long self-tapping screws. Despite the fact that the load-carrying capacity of the SIP panels is very high, they can still bend, so be sure to rely on beams located at a distance of about 0.6 m, as well as in a conventional frame house.

The installation of SIP panels with each other is carried out with the help of wooden beams, which are inserted into the ends of the panels and fastened with short screws with a step of about 15 cm. The dimensions of the bar must coincide with the thickness of the expanded polystyrene layer, and the width is equal to 90 mm.

When connecting the panels, it must be taken into account that nothing can be fastened to the OSB plate closer than 20-25 mm from the edge, otherwise the plate can be damaged. Before installing the connecting rod, it is necessary to apply a mounting foam to the end of the plate onto the expanded polystyrene layer, which will serve as an adhesive and simultaneously fill the voids. Sealing foam is very important, since the cracks and voids will subsequently be sources of micro worms, and, hence, channels of heat leakage. If the roof is also made of SIP panels, then their connection must be made using the same technology.

The boards when installing panels are used solely to cover the layer of expanded polystyrene and protect it from external influences. The boards are inserted into the ends of the panels between the OSB sheets, do not carry a special load and give the facade a view of a completely wooden building.

In order to twist the corners of the building and give it rigidity, long self-screws are used, located approximately 1 m along the entire height of the corner.

Bars and boards, as a rule, have different curvatures, with time due to changes in humidity, the geometric dimensions of the wood change, therefore, no matter how the lumber was processed, it is impossible to connect the elements of wooden structures without gaps. Therefore, if the construction of the CIP-house is observed, all wood connections must be made only through expanded polyethylene, which fills all the free space and eliminates even small gaps and cracks.

It makes no sense to make internal partitions and internal ceilings from SIP panels. The advantage of the SIP panel is that it is warm and provides a better thermal insulation for external walls than the skeleton. External walls are best made from SIP panels, and internal walls, partitions, floors - frame.

The internal and external finishing of the house from the SIP panels practically does not differ from the finishing of the frame house. In the future, the panels from the inside are finished with plasterboard, which will increase fire safety and noise insulation. For the floor, you can use a plywood thickness of 20 mm. For windows and doors, it is necessary to provide hydro and steam insulation of window and door openings with special films. Windows and doors are the main channels of heat leakage, so their selection and proper installation must be approached very carefully. For exterior cladding, you can use any materials, from vinyl siding, to clinker tiles, depending on the owner's wallet and the desire to give the building a certain appearance.

Construction of a CIP panel, reviews of home owners

In the Internet there is a large number of reviews of the owners of houses built using CIP technology, and the bulk of them positively responds about their homes. First of all, it is noted that these houses are very warm and really help to save, which can not be overlooked with the current high tariffs for energy. Secondly, the speed and simplicity of construction are noted: the box of the house is really built in a matter of days, and it is very difficult to admit any fatal errors. Complaints about extraneous chemical smells did not come. If insufficient ventilation is not noticed by all, then insufficient sound insulation is drawn attention.

There are few critical reviews of SIP homes, however, on the video posted with comments, you can often see frank hack-work and absolute non-compliance with construction technology, which leads to unflattering reviews.

The cost of houses from SIP panels is much lower than brick ones, and slightly higher than the frame ones, but thanks to good thermal insulation the difference between frame and SIP-house is quickly compensated by the lower costs for heating and air conditioning. The main amount will be the cost of SIP panels and lumber. The total price is also strongly affected by the class of finishing and facing materials used, installed heating equipment, windows and doors, etc.

Selection of SIP panels

The erection of a low-quality SIP-house is connected, first of all, with the use of substandard building materials and non-compliance with construction technology. Typically, construction campaigns that build houses from SIP panels do not give a big discount on the work performed, but save exclusively on technologies and materials. Often, unscrupulous firms offer a discount for materials up to 50%, but they do not inform the customer that at this price, long screws and sealing film will not be used at all, instead of uneven boards, non-planed boards will be used, instead of quality foam, cheap or foam will be applied in a smaller volume than necessary. As a result of this "saving", the quality of the house will match its price, and the owner will begin to write negative feedback about SIP technology.

Unfortunately, with the growing popularity of the described technology, the amount of falsified products increases, so the quality of the panels used is a matter of quality at home. Of bad building materials you can not build a good house. There are many craftsmen who are engaged in the manufacture of SIP panels in handicraft conditions, not particularly caring about the quality of their products. Sometimes it is not always by sight that falsified panels can be identified. Often, large construction companies specializing in SIP construction and respecting the customer purchase equipment and independently produce panels to use in the construction of obviously high-quality building materials.

For production, an expensive automatic applicator and a powerful press are necessary, and for handicraft production, the glue is applied manually, unevenly and not evenly packed, often simply poured from the bottle. The manufacturer is interested in reducing the cost of production, and in this case this is achieved through the use of poor quality raw materials: OSB boards and low-density styrofoam, less thickness, with a violation of geometric dimensions, etc. At the same time manufacturers of counterfeit products have learned to simulate industrial application of glue. As a result of using poor-quality SIP panels during the construction of a house, its strength, tightness, durability, and harmful substances are released.

In order not to be mistaken when buying building materials and choosing high-quality products, it is first of all to find out where the CIP panels are made, to try to visit the production and see the documents for the manufactured products.

A prerequisite is the presence of all the necessary operating documents for the parts of the SIP panel: OSB-plates, polyurethane foam, glue. Appropriate certificates must be attached to each batch of products. The conscientious manufacturer has nothing to hide, but handicraftsmen will find excuses not to show any documents, or the place of production of panels, which can appear in a nearby garage. It should be especially careful if the house is built by a team, which itself buys building materials, bypassing the customer. Very often they acquire SIP panels in such handicraft industries.

The right choice of building materials is devoted to forums that will help you acquire quality CIP panels, and then your house will be really warm, strong and beautiful.

Construction of SIP panels, though, has its drawbacks, but knowing how to minimize them, it is possible in a short time and relatively inexpensive to build a very good comfortable house.