Known formulas for the preparation of mortar mixtures for foundations, masonry and plaster work are open and reliable information. Moreover, the proportions of solutions are printed on packaging and packing of cement, assuming that the masters know the technology of preparation of cement-concrete solutions. We will graciously show you how to make manual and mechanized mixing.

Content

Concrete grades - parameters and characteristics

Any construction is unthinkable without the use of a concrete solution, which is distinguished by high strength properties and performance characteristics.

The basis of single structures, foundations of houses and structures is a cement-concrete mortar that does not possess a natural radiation background in comparison with natural natural stones.

The industrial production of cement and concrete is highly technological, based on strict compliance with the formula and proportions of batch solution in accordance with the " GOST 28013-89 Building solutions. General specifications».

In addition, the main parameters of a mixture of industrial solutions are controlled and tested according to GOST 5802:

- water retention and delamination capacity not more than 10%

- mobility and average density of solution

- frost resistance and stowage.

Most developers prepare mortars with their own hands in accordance with well-known proportions

concrete solutions.

Helpful Tips

Recall that the composition of concrete solutions and dry mixtures for component content is simple. It is a compacted mixture of binder - cement and sand, water and strength aggregate (crushed stone).

There is a division of the solution according to the consistency:

- ready-to-use mortar mixture of binder, aggregate, additives and a preservative

- dry mortar mixture from water-retarded components

- artificial stone solution of binder, aggregate and zatvoratelya.

The main indicator of concrete compressive strength is marked - from M10, M25, M50, M75, M100, M150, M200 and M400.

Cement M400 and M500 are considered the most in demand.

Mixing of the solution

Manual kneading and the preparation of working solutions using primitive means is no longer of practical interest, in view of the obsolescence of technology. The ideal mixing solution is a special concrete mixer with a rotating drum capacity of up to 1600 liters and a capacity of 5 to 120 m3 / h.

The quality characteristics of mixing the solution determines the percentage of cement.

cement

Adhesive component of the solution is cement, which is divided into categories by the quantitative composition of mineral additives:

- portland cement PC-I, PC-II additives less than 5%, solidification rate high

- mixture with an amount of additives of 6-35%, the rate of solidification is reduced

- the amount of mineral additives is 35% or more, strength is accumulated for a long time.

The self-preparation of the solution begins with the calculation of the proportions of the components.

Calculation of the proportions of the component composition

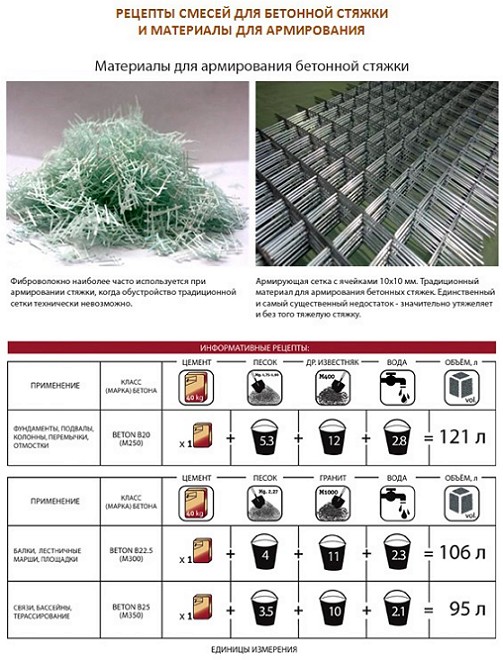

For calculation it is recommended to use ready-made tables of proportions of components and informative recipes. Most developers in practice use commercial cement M400 and M500 as a solution for the concrete floor and foundation.

It must be remembered that water from the total solution mass should be ½ and cover the kneaded mixture.

For example, for a mass of a mixture of 100 kg of M400 cement, 40 liters of water will be required to produce 31 kg of concrete at the outlet.

The proportions for the preparation of the solution according to tabulated values are as follows:

1 part of cement, 1.2 parts of sand, 2.7 parts of rubble, 4 parts of water.

For the preparation of 10 m3 of concrete from cement M500 it is necessary to take:

1 part cement, 2 parts sand, 4 pieces of rubble, with an approximate weight of the material - cement 1500 kg / m3, sand 1800 kg / m3, crushed stone 1400 kg / m3.

Basic technologies of solution preparation

There are several ways to mix the solution using a concrete mixer:

- the calculated and measured volume of water is poured into the concrete mixer, followed by the addition of cement, sand and rubble of the middle fraction

- add sand, crushed stone and cement to the mixer. The mixture was then stirred and water was added.

Specialists consider rational the method of mixing the components of the mixture with the subsequent addition of water, which guarantees the uniform distribution of the solution mass in the process of forced mechanical stirring.

concrete mortar for foundation

Prior to the preparation of the solution, the type of cement is determined. Let's say that with a slight load of the structure or structure, M200 and M250 are given preference to the base, for massive structures and houses from a log or beam, the solution should consist of M350. For brick houses use cement M400.

Step by step cooking technology

Step 1. We select the proportions of the composition of the mixture: cement - 1 part, sand -2 parts with a particle size of 1.2-3.5 mm, 4 pieces of crushed stone of different sizes

1.5-8 cm.

Step 2. We prepare the concrete mixer and start it.

Step 3. Load alternately cement, moistened sand and gravel.

Step 4. Add a measured amount of clean water.

Step 5. We mix the solution to a homogeneous consistency.

Step 6. We check the readiness of the solution.

Step 7. We deliver the mortar for laying.

How to produce a kneading mortar for the foundation from the masonry master shown in the video.

Helpful Tips

The concrete mixer is located near the foundation pouring site. During the preparation of cement-concrete pouring, the test readiness of concrete is made. At the trowel, a small amount of solution is collected and observed. Qualitatively prepared concrete mortar must keep the shape of the roller coaster, not blurring over the trowel.

If the mobility of the solution is high, this indicates incorrect proportions of the components. Refer to the tabular data of the information recipes for mixing concrete mortars for the foundation.

plastering mortars

The proportions and the ratio of the components of the plastering of the walls with a cement-sand mortar determine its non-shrinkage during application and drying. We will suggest that for interior plastering works it is preferable to use cement M200, for external plastering M400.

The ratio of the components is as follows: Ц: П: В 1: 13: 4. Pay attention, in the plaster solution and the masonry mixture, crushed stone is not added.

Step-by-Step Technology

Step 1. We prepare the container for the preparation of the mortar mixture.

Step 2. We fall asleep dry fine-grained sifted river sand.

Step 3. Add a measured amount of clean water.

Step 4. We fall asleep cement and make manual mixing to a homogeneous consistency.

Step 5. We check the readiness of the working solution.

Kneading mortar is shown here.