Taking her for the first time with her manly hands, your head will spin and your breathing will become intermittent. How lovely! Flexible, elegant and refined. Work with her - a pleasure: gently lay on the floor and smooth with your hands. If you think that this is a new long-legged secretary-referent from the department, you are deeply mistaken. It's about the vapor barrier, the faithful friend of the wooden floor of a country house.

Content

On the need for vapor barrier

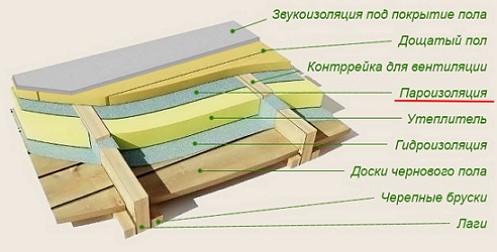

It is known that sex is the most vulnerable part of the construction of a private house. Structurally the floor in an ordinary wooden house represents a multilayered construction on the logs.

Bewilderment on the question: "Do we need a vapor barrier on the floor?" - it's easy to disperse. Steam insulation of the floor will protect lags and boards from steam and collecting condensate, which subsequently penetrates underground into the form of ordinary water. What is a floor vapor barrier device, and what existing materials are better to use for this purpose?

How to choose a vapor barrier material

Let's talk right away that the vapor barrier material for the floor is a thin film or membrane. All vapor barrier materials characterize the heat and insulation properties and the main indicator, namely vapor permeability.

Distinguish the following materials for vapor barrier:

• Polyethylene film

• polyethylene film laminated

• polypropylene film

• diffusion membranes

• liquid rubber.

By what rules, and by what criteria is it recommended to make a choice? Let's say frankly, these vapor barrier materials proved to be a good idea. The question of choice will naturally be the different price of the vapor barrier.

polyethylene film

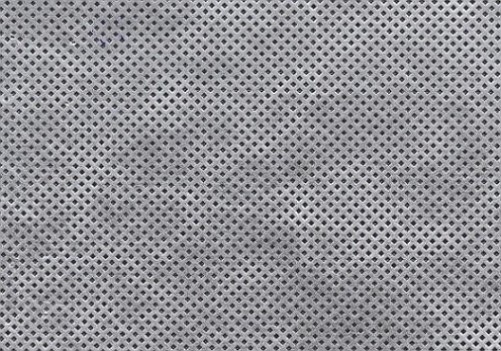

The most famous and familiar in application is a polyethylene film. To purchase a film of more solid qualities - strength, it is reinforced with reinforcing mesh or cloth.

Films reinforced are perforated and not perforated. The degree of vapor permeability, due to the presence of micro-holes in the film, creates a vapor permeability index for an unperforated film Sd = 40-80 m, and for a perforated Sd = 1-2 m. Therefore, a polyethylene film is used to construct a waterproofing system.

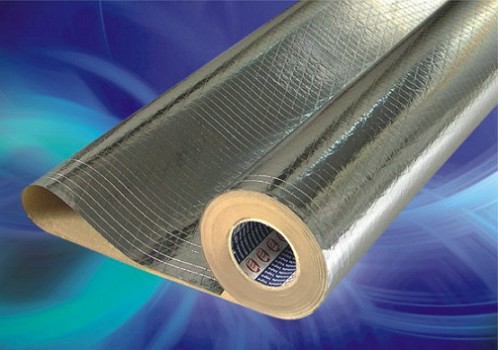

polyethylene film laminated

Polyethylene film, laminated with aluminum, has an amazing, as compared to a polyethylene film, vapor permeability coefficients, namely Sd = 200 m.

In addition, the vapor barrier material reflects infrared radiation, keeping the heat inside the house. Therefore, the use of polyethylene film laminated is recommended for the installation of vapor barrier floors for very wet rooms. Lay the laminated film with the side with an aluminum coating outward in the direction of the house.

polypropylene film

Polypropylene film is a more durable material with an insignificant vapor permeability Sd = 50-100 m.

The structure of propylene and intramolecular bonds are strong and stable.

It is these qualities that prevent condensation on the surface of the polypropylene film. Steam insulation for a wooden floor with film reinforcement with a polypropylene extra layer of viscose and cellulose significantly improved the quality. Due to the structure and qualities of viscose and cellulose, the moisture accumulated on the film layer gradually dries up.

If the polypropylene film has a one-side laminated coating, then it is necessary to place the vapor barrier in the wicker surface in the direction of the room, and smooth - to the heater.

The polypropylene film is laid down by a layer that prevents condensation. It is also necessary to provide a technological ventilation gap between the film and the heater.

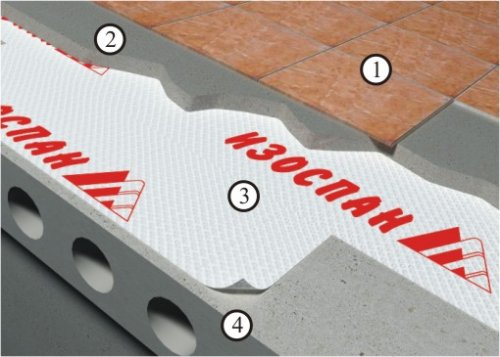

To find out how the vapor barrier of the floor is made, you can use the isospan as an example.

diffusion membranes

When creating diffuse membranes, the effect was based on the absorption and evaporation of moisture from non-wovens from artificial fibers. Moreover, we note that an independent number of layers of the diffuse membrane performs the vapor exchange in accordance with the level of humidity and temperature in the room.

"Intellectual" capabilities of diffuse membranes do not depend on the type and type of membranes - one-sided and two-sided. It's all about the anticondensation layer being created, which is responsible for moisture accumulation and subsequent evaporation of moisture. The cost of diffusion membranes is an order of magnitude higher than the cost of other vapor barrier materials. That's what the skillful use of intellectual capabilities means!

Laying the diffusion diaphragm one-sided produce a rough side to the heater. If the membrane diffusive two-sided - questions on the correct vapor barrier of the floor does not arise.

Where and how to pack the vapor barrier

The main task of the vapor barrier film is to create a unique vapor barrier barrier and prevent the penetration of moisture or condensation to wooden structures. Technologically, the vapor barrier is laid between the heaters and the "clean" floor.

Sometimes in the construction of the vapor barrier provide a second layer, which is placed between the heater and the "rough" floor. Recall that the bottom layer of vapor barrier is topical for the lower floors and socles, because their rough floor is located directly above the wet basement or ground. Practice of work shows that laying the vapor barrier does not require special skills, so you can install the vapor barrier yourself.

Arrangement of steam insulation of the floor in the house

The vapor barrier device will consist of the following stages of work:

• preparatory (preparation of "rough" sex)

• laying the vapor barrier on the floor

• Stacking insulation

• flooring of the "finishing" floor.

Preparatory work before the vapor barrier is made in the processing of wooden structures of the base of the wooden floor, including lags, boards and bars. Treatment is carried out using antiseptic means against mold, fungi and bacteria. Laying the vapor barrier is made from a roll of film. The roll is unfolded and the film is placed on the frame. You can cut the canvas on the strip for ease of use.

The strips are lapped up to 20 cm, then join together with a special tape or ribbon. This will eliminate the appearance of gaps and undesirable slots.

Cloth or strips of vapor barrier are attached to wooden lags using a stapler. Then the laying of insulation in the traditional way. The final stage of the vapor barrier of the floor in the house will be the device and flooring of the "finishing" floor.