Beginning the construction of housing, we should focus on projects that can, at the end, provide maximum comfort and reliability. More recently, the most common building materials for the construction of their own house were foam concrete and brick, which provided a long operational period and were considered harmless to human health. At that time, the houses made of wood, which gained great popularity in European countries, were considered not entirely practical, not beautiful enough, not safe in terms of ignition.

Content

- 1 Revival of construction from wood and fashion for country cottages

- 2 Advantages and disadvantages of frame construction

- 3 Projects of frame houses

- 4 Wireframe construction - technologies

- 5 Frame houses - the order of performance of works

- 6 Frame construction - what materials can be used to build the frame

- 7 Laying the foundation

- 8 What kind of roof for a frame house should be preferred

- 9 The order of performance of works

Revival of construction from wood and fashion for country cottages

For today, wooden constructions surely oppress buildings from other building materials. This is because, over time, it became clear - the tree, the material is relatively inexpensive, the construction constructed of it turns out to be environmentally safe. Plus, the modern frame house at cost is much more affordable, more convenient and practical than a cramped apartment in a multi-storey building with noise from the street and settling on the windowsills with soot. It is quite realistic to build a beautiful, modern, cozy and secure house on a private plot located outside the city by selecting any of the catalog of single-storey houses projects. The money that is worth the apartment in the city, it is enough to build a frame house with a larger area and layout, which suits every particular owner.

Advantages and disadvantages of frame construction

In the most developed European countries, technological construction of frame housing is quite widespread and is recognized as the most comfortable.

For a deeper understanding of the technology of frame construction, the recognition of its greater functionality and the maximum practical use, it is necessary to clearly identify all the pros and cons, in other words, to conduct a comparative analysis with other types of construction of living quarters. First of all, it is necessary to understand what exactly the concept of wireframe construction means and what construction materials will be needed in the course of the erection works.

Projects of frame houses

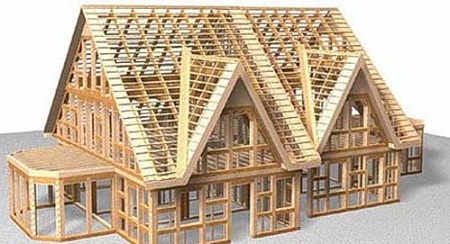

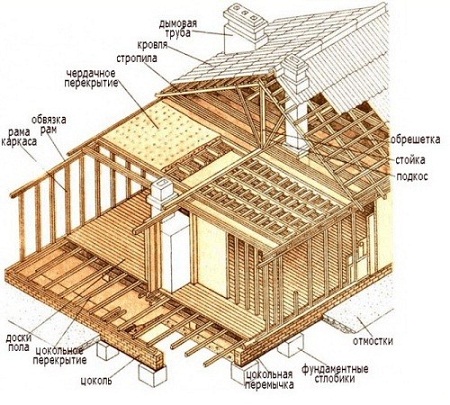

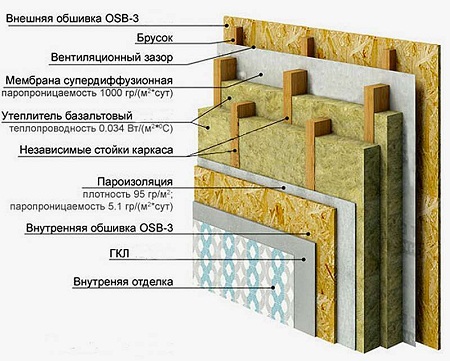

The name "frame" such houses have received not in vain. Their construction is based on the original erection of a frame structure, which is subsequently sheathed outside and inside by specially designed materials for such work. Internal and external work can be produced as molded materials (lining, block house, imitation of timber), and sheet (plywood, DSP, OSB). The space that formed between the inner and outer layer is filled with one or another insulation:

- foam,

- mineral wool,

- glass wool,

- expanded polystyrene.

The basic weight of the structure is evenly distributed throughout the frame. It can be made of both wood and metal. Experts argue that developers who want to become owners of frame housing, order wooden frames on much more often than metal.

Wireframe construction - technologies

The frame base is assembled directly on the plot of the pre-selected and purchased building material. The structures, which are built in strict accordance with the frame technologies, are resistant to deformation, have a high degree of rigidity and have a long service life. Work on the outer skin contributes to a reliable overall strengthening and gives the opportunity to obtain the recommended parameters.

Depending on the method used for the cladding of the structure, two types of technologies are distinguished, their classification takes place depending on which method is used for the cladding of the structure.

Frame-panel technology implies the installation of the frame, its processing and the creation of a thermal insulation system. Those. each of the materials is purchased separately. The cost of this technology is lower, but the construction process is complicated.

Frame-panel version - on the contrary, provides for the use of prefabricated shields of certain sizes, with a layer of insulation already installed in them. On the building site, the boards are delivered ready-made, their assembly is performed using special construction equipment. This technology is more expensive, but it is preferred because of the high speed of building the house. Of the advantages also it should be noted that the shields assembled by the industrial method exclude the influence of inaccuracy of the workers who are assembling the house. Each factory manufactured shield passes quality control and fully complies with building codes. In most cases, the increase in costs is justified - the life of the panel assembly is longer, and the savings in heating the premises is higher.

Frame houses - the order of performance of works

The most significant arguments in favor of frame construction are:

- high economy of building private houses,

- relatively small weight of the structure, allowing to obtain tangible savings on the construction of the foundation,

- high speed of installation, allowing owners to settle in a new house a couple of months after the construction began.

In addition, frame structures made of wood retain heat well, they heat up quickly. The thermal conductivity of walls in frame structures is so low that the thickness of the wall with sufficient heat savings can be only 15 cm. Frame structures are highly rigid and able to withstand forces directed to deformation of walls. A positive moment is the possibility of performing interior finishing immediately after the completion of the construction of walls and roofing - you will not need to wait for shrinkage of the structure.

The materials used in frame construction allow to perform decorative finishing of walls and ceilings bypassing the procedure of additional processing. On the cheaper construction is affected by the plating of the internal surface of the walls with plasterboard.

But despite the obvious advantages, modern frame houses still have some disadvantages.

- In particular, qualified specialists who know the assembly technology well and have the necessary tools and equipment will be able to perform the installation work in a sufficiently high degree.

- Projects of frame houses usually mean the construction of houses with small dimensions, their length should not exceed 20 m, the recommended height - from 1 to 3 floors.

- Before the construction starts, all the wooden structures will need to be carefully treated with antiseptic and fireproof impregnations.

Having conceived the construction of your own house, you should think carefully about whether the frame structure can fully meet all your wishes. If a decision is made in favor of frame construction, then it is possible to proceed with the selection of materials for the construction of the foundation.

Frame construction - what materials can be used to build the frame

Usually, quality wood is used for the construction of the Euro-house, however, a metal frame, which has the following advantages, deserves attention:

- used in the construction of thermorprofile is fireproof,

- it is not affected by putrefactive bacteria,

- its surface is not prone to corrosion,

- the specific weight of the material is not high,

- the service life of such a structure can reach 100 years, wooden structures at best will serve a little more than half a century.

The duration of the problem-free operation of the frame structure is significantly influenced by the quality of the assembly of the structure, its thermal conductivity will depend entirely on how well the seams are sealed. To save on the quality of construction work for these reasons is not recommended - the process of assembling a house is best entrusted to professionals.

Laying the foundation

Before starting to assemble the frame house, you will need to build its foundation, i.e. foundation. Its duration will depend on its quality. For frame construction, three types of foundations are used: columnar, banded and tiled, when choosing a particular type, you should consider:

- soil structure on the site,

- the assumed weight of the structure.

On landing or silt soils it is best to construct a tile foundation - it promotes a uniform distribution of the load on the ground. Its construction begins with the removal of the upper layer of the soil, digging the excavation, creating a sand pillow. The cooker is laid on the prepared substrate.

For a solid soil, both a tape and columnar foundation will be suitable. The main thing is that it is durable and able to withstand the loads that it will have a frame structure with trim. Therefore, before beginning the laying of the foundation, you should thoroughly study the projects of frame houses, taking into account the materials used, to make an exact calculation of the weight that they will have at the end of construction.

What kind of roof for a frame house should be preferred

For the frame house you can choose the same types of roofing that are used in the construction of a brick or wooden house:

- mansard,

- gable,

- multi-clasp.

Most often, developers prefer a gable roof or skylight.

Installation of their special problems does not cause, as a roofing, you can use any of the modern materials, most importantly - that it corresponds to the climatic conditions of the terrain in which construction is carried out. It should also take into account the features that distinguish the project:

- slope of the structure,

- the expected service life,

- financial costs.

As a roofing material you can use:

- steel sheet, the period of its operation lasts about 30 years, the recommended deviation for such a roof is about 18-30 degrees;

- ondulin or bitumen slate has a service life of about 50 years, can be used for roofing with a slope of 35 to 40 degrees;

- metal tile with proper care can serve up to 35 years, the optimal roof slope is 25-45 °;

- asbestos cement slate in the event that it will be painted, it will last about 40 years, it can be laid on the roof with a slope of 25 to 40 degrees.

An important factor in choosing the material will also be the option of using the attic floor - if it is residential, it will require an improved development of the roof skeleton and installation of an additional thermal insulation system.

The order of performance of works

To collect frame houses, the instruction to which is painted in great detail, in principle is not difficult, the main thing is to observe order and take into account even the most insignificant, at first glance, details. The correct assembly algorithm and installation in compliance with building regulations will guarantee the long life of the constructed house.

When choosing a site for construction, you should consider:

- depth of occurrence of groundwater and the quality of the soils themselves,

- features of the climate in the area,

- the passage of various communication systems.

Having determined the optimal location, you can start marking on the ground and laying the foundation. The peculiarity of the foundation for the frame house is that it contains two crowns from the wooden processed beams, then a wood frame is attached to them. If the frame is constructed of metal, then this operation will not be required.

After the carcass is erected, it is plated outside. Simultaneously, the installation of windows and doors. Since the frame house is not subject to deformation, the installation of window openings can be performed during the assembly of the walls.

Next, you need to assemble the thermal insulation system. If in the construction already used shields were used, then after their installation, the inner part is simply covered with sheets of plasterboard.

Only after carrying out all the works connected with the outer walls, they begin to install internal partitions, floors and ceilings, lay necessary communications. The roof is going to last. Next, finish the exterior and interior walls.

The cost of building a frame house is relatively low, to some extent this has become the reason for the popularization of frame construction.

But its attractive moments are not limited to construction costs:

- frame house is functional and comfortable,

- it will last for many years,

- a qualitatively arranged system of thermal insulation will allow to minimize the costs for heating the room and its conditioning,

- materials from which frame houses are made are environmentally friendly,

- the timing of the frame house in operation is extremely small.