If you are tortured by the creak of a parquet, then you can eliminate such trouble yourself. For this, there is no need to change an apartment or move to a dacha. The main thing is to find a local place creaking laths and try to eliminate the "hearth" of the opposite sound. Do you want to learn how to do this?

Content

Why creaks of parquet

A durable floor covering, capable of serving, as it seemed, for ages, is parquet. A warm touch to the feet of the natural material of the parquet boards is a pleasant feeling, to spoil the impression about which only the scratch of the parquet can.

The reasons for the appearance of parquet squeaks are many. The main reasons for the creaking can be called:

• parquet boards have cracked or cracked

• the groove or the ridge in the parquet strip has broken

• there is no technological clearance near the walls

• mechanical movement of the ends or lag occurs

• the fastening elements come out of the attachment points.

However, the list of reasons for the formation of parquet squeaks is abound, so it is necessary to urgently eliminate the creaking of the parquet.

However, the main source of the creaking flooring lies in the parquet slats, and to be precise in its design.

It is necessary to distinguish between parquet boards and parquet shields.

Construction of parquet laths

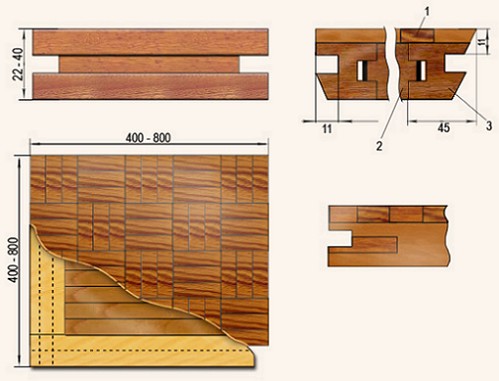

Plank parquet is a plank: the width of 30-90 mm. and the length is 150-500 mm. characteristic configuration. The thickness of the parquet can be up to 15 mm. for solid wood and 18 mm. for the soft. The protruding part of the bar that runs along the edge and the end is called the crest. The groove is a connecting groove with the help of a comb of individual slats. The joint "crest-groove" creates a rigid parquet covering.

Parquet slats or piece parquet, depending on the profile, are divided into two types:

• a configuration II having oppositely arranged ridges and grooves

• configuration P2, having a comb on one edge and a groove on the opposite edge.

The edges of wear are both on the side of the ridge and the groove. On the side of the ridge, the wear edges have a characteristic bevel 3 °. From the side of the groove the edges of wear are straight. Now you understand that any knot, crack or defect of wood on a parquet strip can cause a squeak.

Parquet boards

Parquet boards are a wooden base with an outer covering made of parquet boards. As a rule, parquet boards on the shield have the same geometric dimensions and straight milled edges. Planks are glued to the shield using waterproof glue. Parquet boards have the following dimensions: 400x400 mm. or 800x800 mm.

Laying of parquet (strips or boards) is made on a primed work base after the final drying of the primer coat.

For gluing planks and shields to concrete and cement bases use hot and cold mastics.

How to eliminate the scratch of a parquet

There are enough ways to eliminate scratches and partial repair of parquet.

All methods of eliminating the violin begin with the definition of the local location of the squeak site. This can be a separate parquet board or several located close by.

Methods of fastening the strips to self-tapping screws and "liquid nails"

The first method can be called the simplest. There is an arrangement of a creaking parquet strip, then a hole for a dowel is drilled in the bar. The dowel hole must include the base of the floor.

Then insert a dowel into the drilled hole, which will enter the base and pull the bar. To pull the parquet board is recommended using a self-tapping screw of the appropriate size. Place the self-tapping in the future, it is necessary to fill with a suitable filler according to the color or shade.

Another way to eliminate the defect of the parquet slats when the floor is creaking is the same as when a hole for a dowel is drilled. In this method, instead of self-tapping screws, "liquid nails" are pumped into the hole. Taped with the application of "liquid nails" the bar, is glued to the base and the creak ceases. It remains to decorate the place of drilling with special putty.

Thermal fastening of laths

If the base under the parquet was pasted on the bituminous mastic in "hot" or "cold" ways, then to eliminate the creaking use an ordinary building hair dryer. Using a jet of hot air from the dryer, heat the parquet plates, which creak. A powerful jet of hot air will melt the bitumen mastic under the parquet plate. Then, the die is gently pressed into place. After a certain time, necessary for setting up the bituminous mastic, the parquet strip is securely adhered.

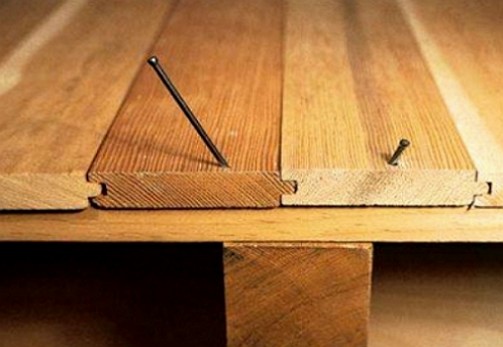

Fastening strips with the use of parquet studs

In the case where the parquet boards were fixed to the boards, the creaking straps can be attached using a pneumatic gun and parquet pins.

If a large number of laths have left the base, then a complete restoration of the parquet by oneself is necessary.

Full dismantling of parquet

Complete dismantling of the parquet will consist of removing the slats, careful preparation of the base, new laying of the parquet, subsequent loops and grinding, as well as the final coating of the parquet with varnish. Restoration of individual parquet slats is as follows. The cracked or split bar is split by a chisel into several pieces. Then the defective strip is removed from the middle, then along the edges.

Removed old glue or bitumen mastic. The resulting depression of the old strip is peeled off from the remains of the wood. Then a single bar is carefully inserted, which should ideally fit into the place of the old one. Making sure that the size of the bar corresponds to the cavity, it is filled with bituminous mastic or parquet glue. Plank is installed in place, surplus adhesive is removed from the surface.

Method of fastening brackets with the use of lubricating composition

There is a way to eliminate the creaking of parquet slats using a special composition based on wax and solvent. Lubricant composition is introduced into the cavity under the parquet with the help of forcibly manufactured micro-holes.

For such purposes a medical syringe with a long tip is used. Any lubricant for creaking parquet laths is fed into the cavity under a slight pressure. After a certain time, the liquid lubricant fills the existing cavities and the creak ceases. However, this "resuscitation" method is not as effective as the method of fastening the slats to self-tapping screws or "liquid nails".