The substrate under the laminate is an extremely important part of the flooring. Laminate is a very delicate material. Put directly on concrete, it will not last long. In addition, a laminate without a substrate does not completely absorb sounds and does not retain heat. The substrate, on the contrary, has waterproofing, heat-insulating, sound-absorbing and leveling properties. It is for this reason that the selection of the substrate is an important part in the process of laying the laminate on the floor in an apartment or house.

Content

Selecting a substrate for a laminate

artificial substrates for laminate

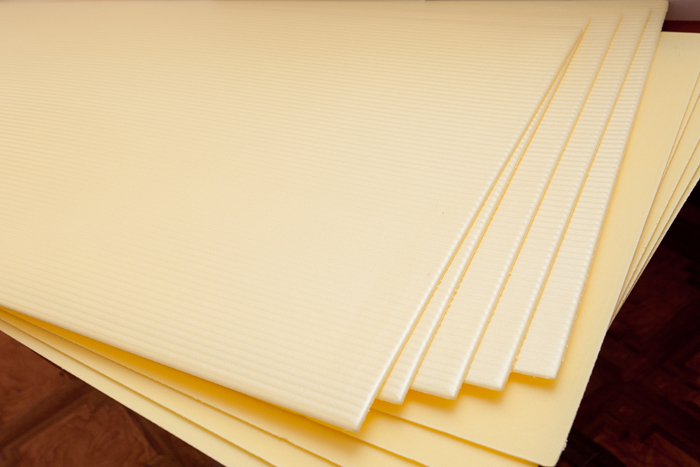

Substrates under the laminate are artificial and natural. Artificial substrates for the laminate are substrates made of foam expanded polyethylene. They are the cheapest and therefore the most common, they are easy and simple to cut and stack.

These substrates do not pass through moisture due to their honeycomb structure, they are resistant to various chemical influences, to attacks of rodents and various insect pests, as well as to the formation of house mold. The substrates of foamed polyethylene foam have excellent sound, heat, and noise insulation qualities.

Among the shortcomings can be called its relative fragility, since such a substrate is thin and easily torn.

After about three to four years of active operation, it loses considerably in thickness due to caking. To increase its performance, such substrates are often produced with a protective layer of aluminum foil.

natural cork substrates for laminate

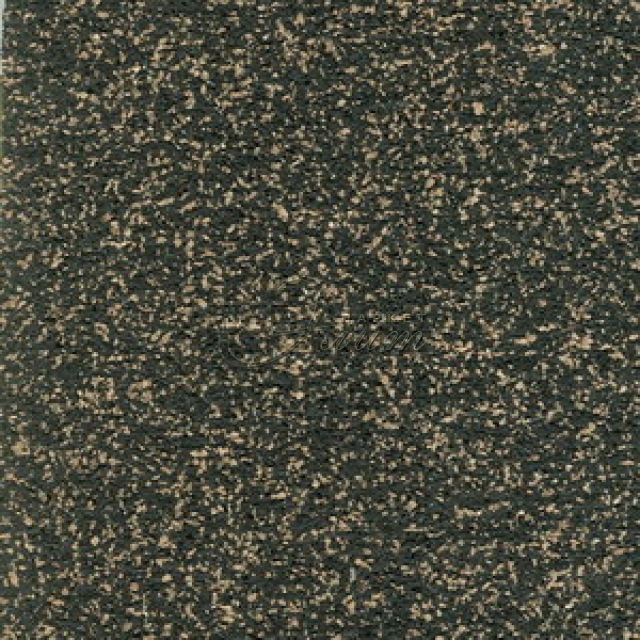

Thinking about which substrate to choose for a laminate, pay attention to the cork substrate, which is made by pressing natural cork chips, usually two and four millimeters thick, either by sheets 915 by 610 mm in size, or by rolls with a width of one meter.

The natural cork substrate under the laminate is the warmest, it does not rot, is not attacked by rodents, various insect parasites and mold. The only drawback is the high cost. For this reason, the purchase of a cork substrate is justified only if it is placed under an expensive high-quality laminate, which is designed for long-term use.

Also you can buy a rubber cork substrate. It is a special mixture of granular cork and synthetic rubber, which gives it advantages over conventional cork substrates in soundproofing properties. It is able not only to reduce various shock noises, but also to suppress vibration of electrical devices.

Bitumen-cork substrates, as a rule, are made from special, so-called kraft paper with bitumen impregnation and are poured on one side with cork crumb in diameter from two to three millimeters. Such a substrate is laid with cork powder down to the floor, providing a micro-ventilation of the floor covering, which is very important in the case of a laminate, from which any moisture that accidentally gets there will be removed.

Thus, the use of a cork substrate when laying a laminate does not imply the additional use of a waterproofing film, which in some way justifies its high cost. In addition, if high thermal insulation qualities of the substrate are required, then the cork warm substrate for the laminate will do the best.

Laying the substrate under the laminate with your own hands

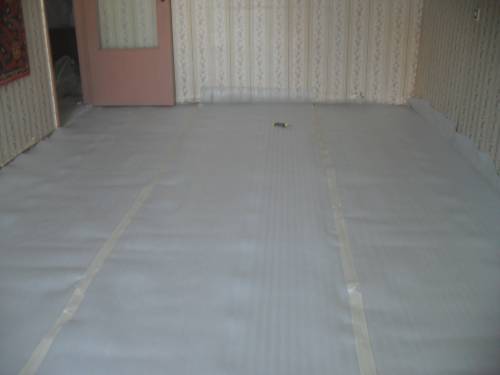

If you follow simple rules, then it is quite possible to lay the substrate under the laminate with your own hands qualitatively. The concrete base of the floor must first be leveled so that there are no large irregularities and differences (not more than 1-1.5 cm) and thoroughly vacuumed, it must be necessarily clean and dry. Then the first layer of the coating is laid - polyethylene film. It is necessary for waterproofing. Then the substrate is laid.

The corrugated substrate is laid down with the side that is with the corrugated surface. Thus, the floor base will be better aligned. A substrate having a layer of aluminum foil is laid with this side up.

The substrate under the laminate, whether in rolls or tile, is laid in the same direction as the laminate panels, without the use of glue.

The edges of the substrate go to the very walls, the strips are put together butt-in, preventing access to each other. Then, the strips of the stacked substrate are joined using a construction adhesive tape or a wide adhesive tape.

Cut the substrate with a construction knife or conventional scissors, pre-measured on the lines applied by any marker or pencil with a meter long metal ruler.

Some think that they can improve durability and best align the surface of the floor, laying the substrate (especially synthetic) in several layers. But this is completely unacceptable, since under such pressure the locking devices of the laminate can break. For an even and reliable base, the thickness from two to four millimeters is quite suitable, this is not enough and unnecessary. All sorts of experiments in this regard can lead to no all works, and the laminate will have to be laid again.

Walking on a laminate with a thick substrate under it is completely inconvenient, since its panels bend and eventually become completely worthless. If the floor is really not even enough, you can simply pick up the thickest substrate with an allowable thickness of not more than three to four millimeters. Although it is better to work diligently on leveling the base of the concrete floor, not hoping to correct its shortcomings due to the thickness of the substrate.

When laying the substrate under the laminate, it does not matter whether the substrate is used by the same manufacturer as the laminate itself.