Russia is reborn, dull buildings and distorted fences are replaced by fashionable modern houses and a fence is a harmonious addition to a beautiful home. At present, at the height of popularity are polycarbonate fences. Below consider the correct installation of the fence of polycarbonate on its own, read the article and be inspired to build a "masterpiece".

Content

Polycarbonate as a building material

Fence made of polycarbonate looks very modern in the event that it is installed by all the rules, in a harmonious combination with metal, stone or wood.

Modern polymeric material in the form of polycarbonate is available in the form of sheet plates, transparent or translucent.

Relying on high quality, sufficient strength, low weight, resistance to atmospheric precipitation, the ability to take various forms - this type of building material has been widely used in construction, especially when installing roofing structures for various partitions, of polycarbonate designers have created many beautiful hanging designs.

Modern fences made of polycarbonate pleases the eye and surprise with diversity.

Quite a wide scale of colors of sheet polycarbonate, different sizes of the sheet, the possibility of selecting the building material for thickness - allows the user to select the material he needs.

Advantages of polycarbonate

The merit of modern polycarbonate should include the following points:

-high stability in relation to atmospheric phenomena;

-long service life;

-stability to high loads;

-No corrosion;

-relatively affordable price;

-a large selection of color palettes;

-small weight;

-Easy installation method;

-Material is able to keep the given forms;

-Excellent combination with other building materials (stone, brick, metal and wood).

Forged fences are the dream of many homeowners, but often it stops not only the high cost of forged fence, but also the insecurity of residents from the views of passers-by, the possibility of penetration of small animals and poultry through the fence.

The forged fence in combination with polycarbonate solves all of the above problems and modern fences become an architectural masterpiece.

Disadvantages of polycarbonate

Unfortunately, there is no ideal building material and polycarbonate, like other building materials, has its drawbacks:

- Polycarbonate can be turned into ruins if desired. Therefore, if you feel that there is a risk of vandal attack, it is unlikely that polycarbonate will be suitable for building your fence;

polycarbonate sheets only in the frame of other building material acquire high strength. Thus, if you decide to build a fence of polycarbonate, take care of the quality of the load-bearing elements of the fence. The higher the load-bearing elements, the more rigid the polycarbonate fence will be;

-a beautiful fence, especially if it's a forged fence with polycarbonate - it costs a lot of money.

Tools assistants and necessary materials

If you decide to build a polycarbonate fence on your own, in any case, a sectional fence or tape, mounted on the spot, you need the following equipment:

-lopats;

-saddle drill;

-measuring tool;

-Bulgarian;

screwdriver and self-tapping screws for metal;

-Screwdriver Set;

-building level;

- capacity or concrete mixer;

- cement, crushed stone, sand;

- profile pipes for supports and frame, in accordance with the size of the future construction;

- reinforcing wire, for arrangement of the foundation;

- primer for metal and paint.

Preparation of the foundation for the future fence

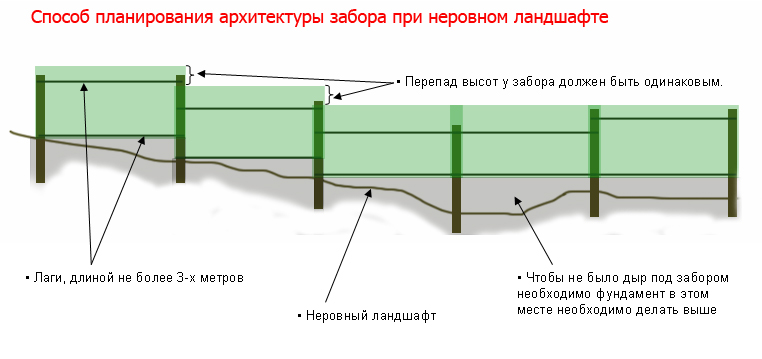

Before digging a trench under the foundation, using a construction cord, you need to make a markup, create a line of future fence.

To do this, drive the pegs to the starting point of the future fence and at the end of the fence.

If there are any turns in the fence, pegs are also put in these places.

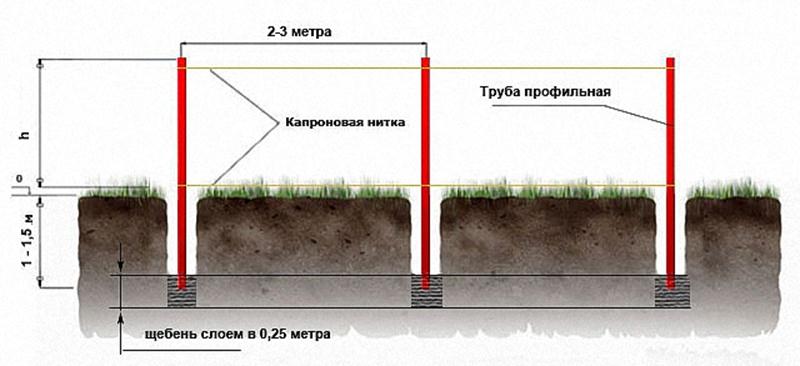

With the help of a garden drill, in the ground holes for corner supports are drilled with a depth of at least 1 meter.

At the bottom of each hole is a sand cushion, on which the angled support is installed.

After the poles are aligned vertically, with the help of the building level, the posts must be fixed and filled with concrete.

In this case, it is necessary to observe the rules for installing the foundation for the fence, namely:

- the depth of the foundation is digested in accordance with the depth of freezing of the soil (depth of freezing from 0.8 to 1.2 meters);

- depth of installation of supporting poles 10-20 cm deep.

-the width of the foundation under the fence is not less than 30 cm;

- Supporting posts are fixed with concrete in the cells, the dimensions of which are a square of 45x45 cm.

After the angular columns are exposed, the pits for intermediate supports are drilled, according to the marking, but to increase the strength of the fence, the intermediate supports should be located at a distance of no more than 2 meters from each other.

If a continuous band foundation is made, the trench digs along the entire length of the fence, at least 70 cm deep, the intermediate posts are installed in the manner described above.

To prevent the foundation from swelling, reinforced rods are laid along the entire length in the form of a metal contour and are connected together by a metal wire.

After checking the horizontal of the foundation and the vertical of the supporting poles and intermediate supports, the foundation is poured with concrete.

After the concrete takes the required strength, it is possible to start welding operations, to connect all elements of the fence frame.

At the end of the welding work, we proceed to the cleaning of the seams, to the processing of the entire structure with a primer and paint.

Tip: if you own a welding, create metal sections in the form of an ornament, a beautiful metal pattern will not only stiffen the fence, but will also save polycarbonate from the impact of stones and sticks in strong winds and embellish your fence.

Brick fence with polycarbonate

The brick fence with polycarbonate looks very nice against the backdrop of the brick house, but the construction will take more time, as the brick columns must dry out, and build them much longer than the metal frame, the price of such a fence will be higher than the previous one.

Polycarbonate, advice of professionals working with polycarbonate

For proper installation of cellular polycarbonate sheets are oriented in the direction of the stiffeners.

If the sheet is not placed correctly, polycarbonate may crack. Incorrect installation of polycarbonate entails stagnation of condensate in polycarbonate honeycombs, and stagnation of water leads to clouding of the sheet.

To cut polycarbonate, it is necessary to use a grinder with a wood cutting disc or a circular saw with fine teeth.

The edges of polycarbonate sheets must be covered with adhesive tape or plugs.

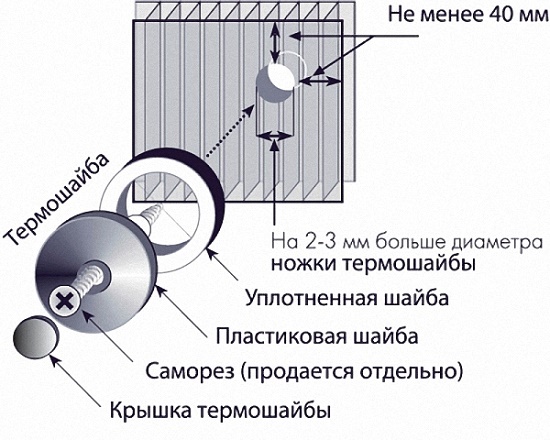

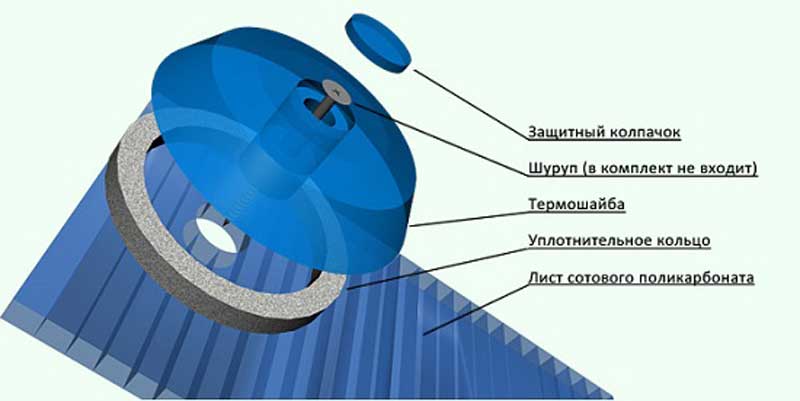

The joints must have a thermal gap, i.e. the hole for the screws should be 2-4 mm larger than the diameter of the screw.

In order for polycarbonate not to crack at a temperature drop, the sheets should not be tightly clamped with screws.

Like any material, polycarbonate should have a gap for thermal expansion.

Protective film from sheets of polycarbonate is removed after the installation of the fence is completed.