The strength and reliability of the foundation of any structure depends on how much quality materials were used in its construction and whether the technologies were sufficiently sustained. One of the important components of a solid foundation is a reinforcing mesh. When choosing an armature, you should pay attention to the material of its manufacture, the diameter and the conformity of its type to the requirements.

Content

- 1 What is an armature?

- 2 Fittings for the foundation, what characteristics should be taken into account when choosing

- 3 Fiberglass reinforcement and its features

- 4 How the reinforcement for the foundation is selected

- 5 Metal fittings - material of what class can be used when laying the foundation

- 6 Armature with what type of profile it is desirable to use in the construction of the foundation

- 7 How to knit reinforcement for a foundation

- 8 How to calculate the valve

What is an armature?

The armature is one of the types of rolled metal. When the monolithic foundation is formed, the metal frame of the future base of the house is created from it, while the metal rods are placed in the thickness of the concrete. The valve is also used to connect fragments of prefabricated monolithic foundations, fastening is carried out using welding or spring clips made of steel. The ability of the reinforcement to withstand the stresses directed to compression and tension makes it possible to increase the strength of the entire monolithic web, to prevent the appearance of cracks in it.

Technological processes for the production of reinforcing bars can be different and result in:

- core hot-rolled reinforcement, resembling a rod having a smooth or ribbed surface;

- periodic, with a ribbed surface, allowing to obtain excellent adhesion to concrete, giving the monolith sufficient strength, the diameter of the reinforcement of this type can be different, it is sold in coils for sale;

- cold-drawn reinforcement in appearance resembles the previous one, but the manufacturing technology has a completely different, produced without heating.

Release reinforcing bars are manufactured in accordance with the standards of GOST.

Choosing a reinforcing material for the foundation should carefully study its characteristics. In accordance with the type of foundation, a reinforcing material of a certain class is chosen.

Fittings for the foundation, what characteristics should be taken into account when choosing

First of all, the choice should be made based on the type of foundation - usually prefer long steel bars, length 6 - 11.7 m. Diameter of the reinforcement, depending on the complexity of the foundation, can be from 8 to 14 mm. In some cases, a thicker material with a diameter of the order of 40 mm may be required.

The steel reinforcing material is different:

- strength, exceeding the strength of the composite analog with the same specific gravity almost 9 times,

- elasticity, the ability to withstand significant load on the deflection,

- wide spread, the possibility of a quick and trouble-free purchase,

- possibility of bending,

- resistance to the impact externally,

- a wide range of diameters - from 6 mm to 80 mm

- relatively large length - up to 11.7 m.

Fiberglass reinforcement and its features

This composite reinforcing material is made on the basis of glass wool - a polymer made from epoxy resins. GOST 31938-2012, which denotes this metal-plastic material is legal from the beginning of 2014. Although this reinforcing product can be considered a novelty, it has already managed to gain fame and even gain some popularity. In the construction industry, another type of reinforcement was found - basalt plastic.

Although the fiberglass reinforcement has not yet been able to compete on an equal footing with the rebar traditionally used in the construction industry, it is necessary to pay attention to its positive properties:

- it is favorably distinguished by a low cost,

- its specific gravity is quite small, it is almost 4 times lighter than the similar thickness of the steel rod, this will allow to obtain significant savings in loading and transportation,

- its output is produced in rods of various lengths, in demand in construction,

- the material has a high elasticity index,

- its strength at breaking load is 2.5 times higher than the strength of the metal.

Like all polymers, GRP is a poor conductor of heat, which eliminates the formation of cold bridges and prevents additional losses of thermal energy. The temperature range in which the polymer material can be used is quite wide, ranging from -70 to +100 ° C. Unlike a metal analog, it does not create a screen effect and does not interfere with the passage of electromagnetic waves. The impact of alkaline and acidic media, as well as sea salt, moisture, any other corrosive environment, does not exert a destructive effect on the surface of the composite material and does not cause corrosion in it. Polymer reinforcement has all the signs of a dielectric and is not a conductor of an electric current. The diameter of the polymer reinforcement varies between 4-20 mm.

The shortcomings of this material are:

- the inability to give it an arcuate shape,

- impossibility to perform connection by welding.

How the reinforcement for the foundation is selected

To perform the correct calculation of the reinforcement, you first need to determine the type of foundation, the erection of which will be the best option for this type of soil. In this case, it is necessary to take into account the load-carrying capacity of the soil and the loads that the building built on its surface will provide. Accordingly, the selected parameters are selected armatures and the total amount of materials is determined.

Taking into account the chosen type of foundation, the required thickness of the reinforcement bar is determined, and in calculating the cross-sectional area of the rod and the class of its marking. In the event that a heavy building is planned to be erected on a weak ground, reinforcement should be installed whose diameter will exceed 16 mm.

If we talk about what kind of reinforcement for the foundation is not suitable - then we can say with certainty that it will be irrational to use a rod with a diameter of less than 10 mm - this can not withstand even moderate loads.

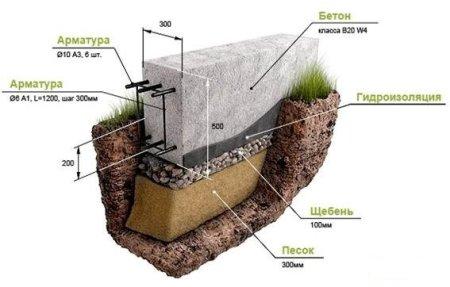

When building a tape-type foundation, the calculation will be somewhat different, the reason is a non-standard configuration of the foundation, its width will be smaller than the height. This non-standard situation makes it possible to use a small thickness of reinforcing bars, about 10 - 14 mm, when constructing a strip foundation. Perform tape reinforcement from below and from above, laying the bars in the longitudinal direction.

Metal fittings - material of what class can be used when laying the foundation

To make the right choice of the material you need in a particular case, you need to understand a little about the marking applied to it:

- The presence in it of the letter A indicates a thermomechanically densified reinforcement of hot rolling.

- The rolling material marked B is cold-deformed.

- The letters A and B also determine the tensile strength of the material.

- The presence of the letter C in the marking indicates that the material can be welded.

- The mark of increased corrosion resistance of the metal is denoted by the letter K.

- The letter P denotes a material with an increased adhesion to concrete.

- According to the state standard, the yield strength of the material should be 500 MPa.

Construction standards require the use of three types of reinforcing bars in the construction of reinforced concrete structures:

- smooth or fluted, hot rolling, with a diameter of 6 - 40 mm,

- corrugated, strengthened thermomechanically, with a diameter of 3-12 mm,

- corrugated, cold-deformed, 3 - 12 mm in diameter.

To create the foundation of the foundation, it is customary to use hot-rolled reinforcing bars, corrugated or smooth. It is allowed to use rolling material of several classes, as a rule, their abbreviation contains symbols:

- A-I brand A240 (with a smooth surface), the optimal version of its use - as a connecting material for corrugated reinforcing fragments of intrafundamental structures.

- А200С, АIII, А400 (corrugated), this is preferable to give preference - the connection of concrete with an uneven surface is more qualitative, while providing fairly high resistance values under tensile and compression loads.

- It is acceptable to use the following types of reinforcing bars: А500 (П and С), В500С, А-II (А300), В500.

Armature with what type of profile it is desirable to use in the construction of the foundation

The types of reinforcing bar profiles can be different. Whereas earlier in the construction of foundations the preference was given uniquely to the material with a circular profile, today the builders prefer a more complex four-sided crescent or sickle-shaped profiles called the euro profile.

Among the disadvantages of such reinforcement, it should be noted the reduction in the area of rib crushing, which entails such negative phenomena as a decrease in the strength of reinforcement bonding and a decrease in their rigidity index. Advantages of the europrofile are to increase the endurance of each rod, which in turn helps reduce the risk of deformation of the frame under the influence of loads.

How to knit reinforcement for a foundation

As practice shows, the laying of fittings on level runs will require the same consumption of steel and polymer material. Particular attention should be paid to the corners - the nodes of the bundles of reinforcement must in no case coincide with them. Avoid the situation can be using steel rods - to bend them at the right angles can be without much effort. With polymer reinforcement, such an operation will not be possible. If the reinforcement is carried out with polymer rods, then it will be necessary to purchase additional corners.

Knit steel reinforcement in several ways.

Welding, used most often. Problems with this method arise when the need for welding rods with a thickness of about 20 mm. Welding arc has too high temperature, under the influence of which hardened rods lose strength.

A positive aspect in the use of welding knitting is the possibility of some material savings - do long overlaps in the junctions will not be required. Specialists warn: welding joints can not be carried out when constructing shallow foundations located on cloddy soils, in case of subsidence of the ground, a risk of a skewing of the entire foundation will arise.

Wire, this method increases the consumption of material, at the joints the material must overlap, it should be between 0.5 and 1 m. Special requirements are imposed on the strength of the wire, its consumption per mating is about 20 cm.

The mating with the help of a pistol is carried out with the help of steel staples, the lapping with such fastening should be about half a meter.

The binding of the polymeric reinforcement can be carried out with the help of plastic clamps, the overlap of the material is up to 50 cm.

How to calculate the valve

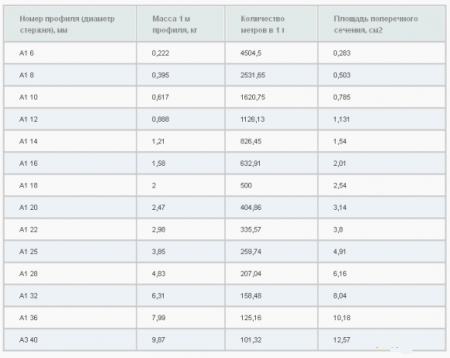

In the calculation, the following points should be taken into account: the creation of a belt structure will require the installation of two tiers of the grid, the upper one - to prevent the possibility of tears in the period of punching, the bottom will protect the foundation from damage when shrinkage. The amount of wire required for matings will be determined in the course of the calculation. It should be noted that for rolling rods you can use class A1 rolling, its cost is lower, for longitudinal rods - its class must be at least A3.

It also takes into account the need to round the corners and the elongations of each rod unit, while the lap length should be 1 m.