One of the coldest places in the bath, and, in particular, in the steam room, is the floor. Very rarely, the temperature on the surface of the floor rises above 25-30 ° C. Proceeding from this, different materials can be used to build a floor in a steam room room - from ordinary clay or earth to tile. One of the main tasks in the process of installing a floor in a therma is to ensure effective water drainage from the room.

The floor covering in the therma can not be made from materials of synthetic origin - for example, linoleum, since it can release harmful compounds to people, even with a slight increase in temperature. The floor in the therma should have an acceptable temperature - few people like to walk barefoot on the cold floor while taking bath procedures. Below we will tell you how to make a floor in a steam bath, consider several types of flooring in a steam room, subtlety and nuances of work.

Content

Floor cover variants for the steam room

It goes without saying that before you start making sex, you need to decide what material to use for this. And it needs to be done before the floor is ready.

wooden floors in the thermae

Do from such breeds of wood, as an oak, a pine, a fur-tree, a larch, a fir, и.т.д. It is best to choose in favor of coniferous species, because of the high content of tar in them. In addition, boards from coniferous species are not so slippery. Oak flooring is also very durable, but it will cost the owner of a bath much more expensive.

The wooden floor in the therma can be leaking and non-flowing.

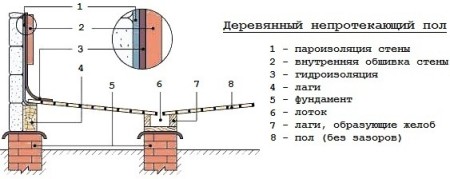

The non-flowing plank floor is easy to make.

For this purpose, the lags are deepened about a third into clay, earth or concrete. On top of the logs, boards are sloped under a slope toward the drain for water. In the place of flow, a grate is made, which is arranged for a dredge to collect and drain water, from which a diversion into the sewer, a septic tank or a cesspool is made. This method is the easiest and inexpensive, however, there is one rather important disadvantage - boards of non-draining floor with intensive operation of the bath do not dry completely, and soon inevitably begin to rot. In addition, the non-flowing floor will always remain cold.

The flowing floor in the steam room is made as follows.

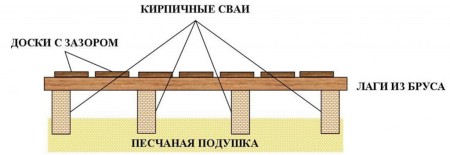

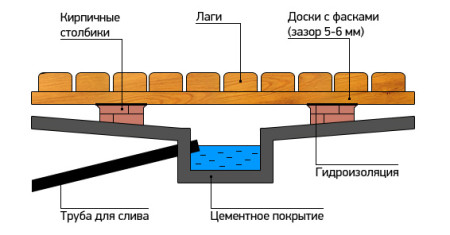

First of all, a small layer of medium-sized rubble mixed with sand is poured directly onto the ground. On top is laid a layer of concrete under a slope to the place of collection of water, which must be airtight (made in the form of a brick pipe or a ring of concrete). Stock, playing the role of waterproofing, equip before you begin to make boardwalk. After this, the board is laid on top with a clearance of 5-6 mm. The gap is necessary for water to flow between the boards, even if they swell strongly.

Important point: the floor in the steam room and in the washing room can be started only after the bath is ready for the water drainage system and the foundation for the oven.

An important role for the durability of the finished wooden floor in the steam room is ventilation, so do not forget about it. In addition, it is possible to efficiently remove moist air from under the floor using an oven stove-heater. As an option, make the connection of the floor with the sub-floor using a box of thin sheet metal.

tiled floor in a steam room

In practical terms, one of the most convenient and reliable. It is durable, does not rot, it is easy to wash. Since ceramic tiles can be heated quite strongly, wooden boards or grilles are installed on such a floor, which can be easily removed and put out after bathing procedures to dry it. To combat mold and fungi, antiseptics for sex are used. Since today there are a lot of options for the design of ceramic tiles, you can choose any you like, including "under the tree." Along with the floor, it is also recommended to tile the lower part of the walls in the steam room, as it is most dirty.

concrete floors in the thermae

Concrete floors in steam rooms can be found quite often. Sometimes even without finishing.

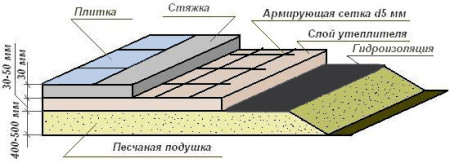

Since concrete perfectly resists the effects of moisture, it is used in all rooms where the humidity is greatly increased. Let's consider one of the ways to install a floor in a steam room made of concrete.

The base for concrete is made of a layer of sand and rubble of 10 centimeters each, which are carefully compacted. On top lay a layer of insulation thickness of 3-5 centimeters. For this, claydite, thick felt, or, as an option, pearlitic screed: 1 part of cement, 3 parts of water and 5 parts of perlite can be used. On the layer of thermal insulation, if it is made of felt or expanded clay, lay a layer of concrete 5-8 centimeters thick. Cement pearlite insulation is poured with concrete in a week. The layer of concrete is about 3-5 centimeters. After the concrete has completely hardened, the surface is finally leveled with a strong cement mortar, after which a ceramic tile is laid.

The concrete floor in the room of the steam room and washing is necessarily made with a slope towards the drain. That the floor normally dried up and for removal of surplus of moisture from a premise in the base of a bath make apertures for ventilation.

This will also help to get rid of the unpleasant odor and the appearance of rot. To the concrete floor in the steam room was as strong and durable as possible, the base under it is made of large gravel, then the floor is insulated in the steam room, its waterproofing, and then proceed to the finishing works.

Differences in the arrangement of floors in different rooms in the bath

Briefly, we can make flooring in different rooms of the bathhouse.

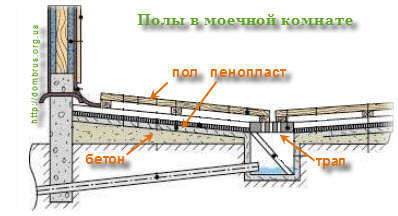

What sex in the steam room you need to do - we told you above. As for the washing, then, because of the very high humidity, it is not profitable to make the floor of wood, as it will quickly rot. It is best to make a concrete floor with ceramic tiles.

If the means are not allowed, the concrete can even not be lined, but wooden shields or gratings can be laid on top. For the dressing room, a wooden flooring on the supports will fit, so that the floor dries quickly. For this reason, the floor in this room is often made double - consisting of rough and clean decking.

Rough flooring must necessarily be treated with formulations to protect against fungus, mold and fire.

In rooms where the humidity is not high, for example, in the rest room you can use a laminate and linoleum.

Floor waterproofing

This issue should be considered at the very beginning of the construction work, because the building of the bathhouse must be protected from moisture not only from the outside, but also from the inside, and special attention should be paid to the insulation of the floor. The drain is placed at the lowest point of the steam room for complete removal of water. For this, as we have already mentioned, the floor is made with a slope.

After the base of the floor has dried, it is thoroughly cleaned, primed and covered with a waterproofing solution.

You can insulate the floor with roll-on backing materials. To do this, the concrete surface is covered with a layer of mastic in two or three layers, the waterproofing material is glued to the treated surface, and only after this is done - with tiles, wood, etc.

If the waterproofing in the steam room is done correctly, then you do not need to additionally process the wooden floor, the board should "breathe". If the floor is treated with impregnation or paint, this will adversely affect the health of people taking bath procedures, since these materials emit toxins at high temperature.

The best way is to simply polish the plank surface of the floor, this will be enough.

Several important nuances in the arrangement of sex in the steam room

• The height from the ground to the floor surface must be at least 30 centimeters.

• For a wooden floor board with a thickness of 25 to 40 millimeters is best, it is also possible to use pile boards.

• It is desirable to lay logs on brick posts.

• For screeds, you can buy ready-made dry mixes or make a solution yourself (cement grade 500, sand, water, liquid glass).

• How to make a water drain, you need to decide before you make the floor.

• A slope towards the drain is mandatory.

• Be sure to take care of the normal water drainage from the steam room and the washer to the sewer or septic tank.

As you can see, making the floors in the steam room with your own hands is not so difficult, even if you do not have the necessary experience. The main thing is to carefully study the theory and follow the recommendations. For a better study of the issue, you can view the video below: