Agree that when installing gas-concrete blocks, glue plays the main role. It is on the properly prepared adhesive mixture that each block is applied. Here, as a sapper, you can not make mistakes, because the setting time of the glue solution is minimal. What are the criteria and criteria for choosing glue?

Content

Why we choose glue for blocks

Before the construction of the house starts from blocks of aerated concrete or gas silicate, the question arises: "What kind of building mix should I use?". In the vast majority of preference is given to the glue for laying aerocrete blocks.

Why is the glue, and not the cement mortar, widely used? Compared with traditional cement mortar, adhesive mixtures designed for aerated concrete blocks have the following advantages:

• excellent ductility

• high adhesion, moisture resistance and frost resistance

• ability to cure without shrinkage

• Insignificant setting time.

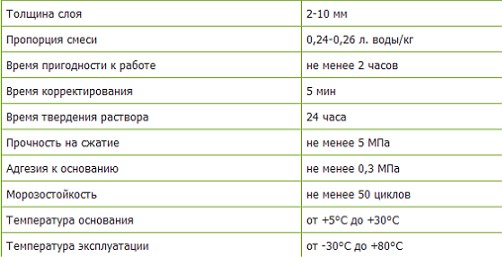

When choosing a glue intended for laying aerocrete blocks it is necessary to familiarize yourself with the main characteristics that fully give an idea of its capabilities. These are the characteristics:

• grain size of the filler adhesive

• Operating temperature of application

• thickness of applied layer

• consumption of material and water

• Drying and holding time

• Mason correction time.

It is these parameters that give a complete picture of the adhesive composition, beginning with the preparation of the glue mix and ending with the possibility of correcting the masonry of a separate block.

Naturally, all these qualities take place due to the composition of glue mixtures.

Composition of the adhesive for aerocrete laying

Domestic and foreign development of manufacturers allowed to obtain a unique material, plastic and elastic, with excellent adhesion.

The composition of the adhesive for aerated concrete blocks includes:

• the main link - quality Portland cement

• fine sand

• polymer additives - modifiers.

The classical formula "3 in 1" works flawlessly and this time. Polymer additives not only contribute to the improvement of gluing abilities, but also fill in the formed voids or irregularities, keeping the moisture inside.

Helpful Tips

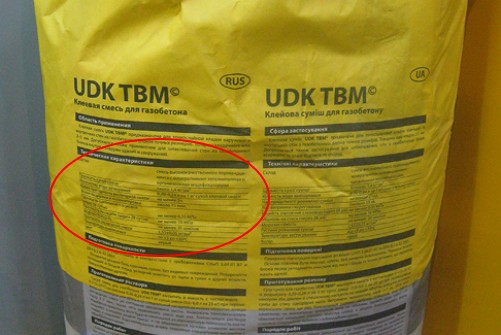

Choosing and acquiring a glue mixture for gas-concrete blocks, it does not hurt to study its composition. This information is kindly provided by the manufacturer, you can read and study it on the label of the packaging bag or container. Glutinous mixture has a cost twice as much as cement.

Recall that the main advantage of the glue for laying gas-concrete blocks is the ease of use and tremendous ease of use. However, in order to ensure that the process of applying the adhesive solution is not overshadowed by anything, it is necessary to make a preliminary calculation of the adhesive for aerated concrete blocks.

Calculation and consumption of glue on aerated concrete blocks

When calculating the preparation of the working adhesive composition, we fully trust the manufacturer's recommendations. Therefore, it does not hurt to read the instructions for use, where the process of preparing the mixture and its proportions is available.

Calculation of glue and its subsequent acquisition is more expedient to carry out on one cube of aerated concrete. In practice, the average consumption of factory-made glue is one bag (25 kg) per cube of aerated concrete. However, such figures can be considered approximate, because the main material consumption will depend on the qualification of the mason and the season of work.

It is necessary to distinguish glue mixtures intended for work in winter and summer. The summer mixture is applied in a temperature regime up to minus 10 degrees, and the winter glue mixture to minus 20 degrees.

Glue, in winter and summer, in one color?

winter glue

When carrying out construction work from aerocrete blocks by oneself in winter, when the temperature is 0 ° С, winter glue must be chosen. Temperature limits for work with the use of winter glue leave minus 10 ° C.

What are the features of winter glue? We will not be mistaken if we say that the distinctive feature of winter glue is its gray color. In addition, the characteristics of frost-resistant glue intended for aerated concrete blocks are that the composition includes antifreeze additives that prevent and rule out the possibility of formation of "cold bridges".

Due to minimal heat loss, winter glue is used for external and internal works. The consumption of winter glue material is 25 kg / m3. The amount of water for preparing a working glue mixture is 5.5 liters per 25 kg. The cost of winter glue for aerated concrete blocks is more than the cost of a similar summer glue.

Helpful Tips

Keep the bag with frost-resistant glue is recommended after all in a heated room. Preparation of the working solution is carried out with warm water with a temperature of + 60 ° C. The temperature of the finished adhesive solution must be at least + 10 ° C, and the application time should be about 10 minutes, including the time for adjusting the masonry of the individual unit.

Block of aerated concrete, on which the adhesive solution is applied, must be cleaned of snow. Therefore, hurry with applying the glue mixture and laying the blocks.

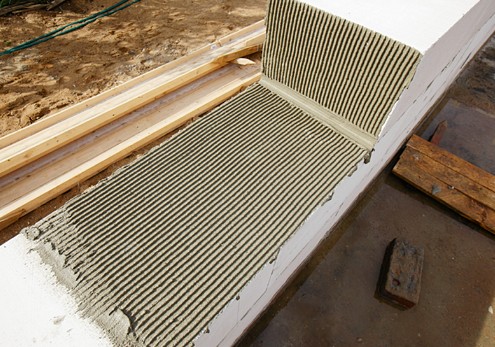

Application of the adhesive solution is carried out using a notched spatula, a special carriage or trowel on a pre-wetted surface. The thickness of the adhesive layer is 3 mm.

The subsequent block is laid on top, pressed and leveled using a rubber kyanka. If the stacking of blocks is carried out in hot weather, a quick drying film is used, which is placed on top of the stacked row.

The market of manufacturers of a product for gluing annually replenishes all new glutinous structures. In order not to make a mistake with the choice, it is recommended to purchase glue from well-known manufacturers. Let's name the names of companies whose products are in high demand:

• Aero Stone®

• Azolite

• Ytong

• Ceresit

• Ceps

• Establish SELFORM T-112.

How to qualitatively produce a laying of blocks of aerated concrete will help you video.