It is known that the choice of technology for installing plastic windows is based on the type of wall installation. The only thing that unites the process of installing windows is the strict observance of the installation sequence. A professionally created wooden window is considered the top of the skill. The best experts kindly share secrets and useful advice.

Content

Technology of installation of PVC windows

The window industry and the range of its products are now sharpened to meet the needs of developers. The self-installation of windows is of a total nature, and the range of products is designed for a wide range of consumption.

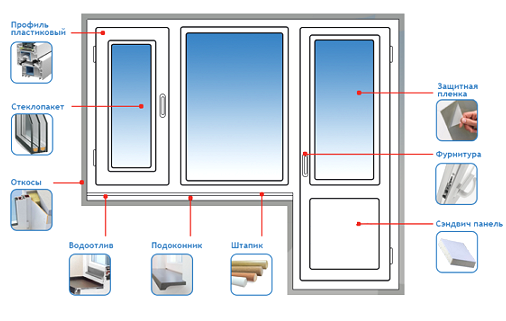

Moreover, the universal consolidated normative document is regulated - a technological assembly card, on the basis of and under the guidance of which confidence in the correctness of the operations is created. Any set of PVC windows, besides the accessories of plastic windows and nets on windows from mosquitoes to plastic hinges, includes more than a detailed installation instruction.

Recall that the installation, installation and adjustment of the operation of the sash window, after measuring, calculating and selecting a plastic window, implies the sequence:

• dismantling and preparation of the opening

• dismantling of the window leaf

• installation of frame construction

• installation of waterproofing

• Fixing the frame and mounting the tide

• hanging the window leaf in place

• mounting the handle

• activation of loops and springs

• Check the operability of the window.

Proven in practice scheme works flawlessly, until the developer does not face the need to install a window in a wooden chopped house.

Helpful Tips

Know the need for measurements in order to calculate the plastic windows, everyone knows. It is known that ideally smooth rectangular openings practically do not exist. Therefore, to adjust the dimensions, it is recommended to measure the perimeter of the window, its diagonals.

To calculate the overall width, the formula is used: L = L pr - 2 q, and for the overall height - H = H pr-q,

where:

L ave - the width of the opening (mm)

H pr - height of the opening (mm)

q - width of the mounting gap (20-30 mm) GOST 30971-02.

The received sizes are initial for manufacture of assembly actions.

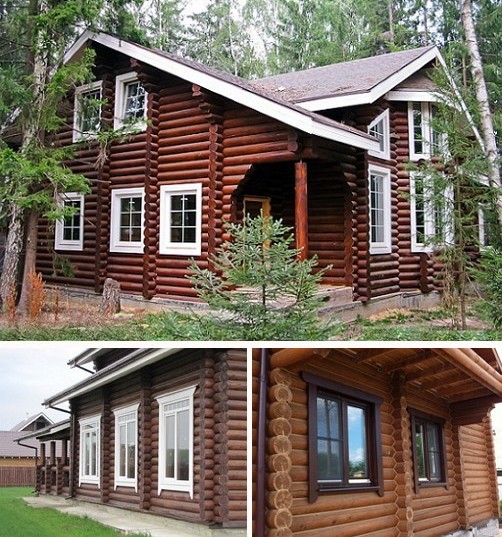

Installation of PVC windows in a wooden house

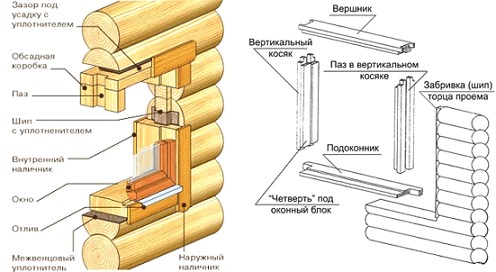

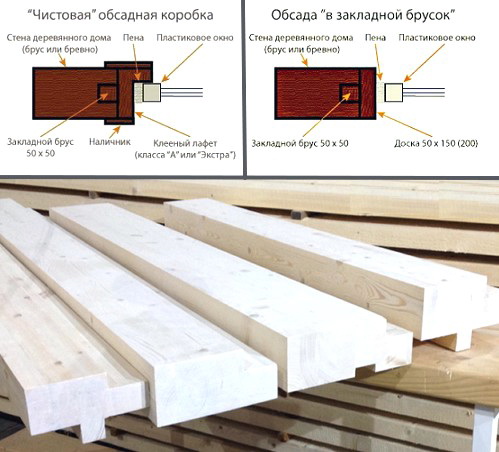

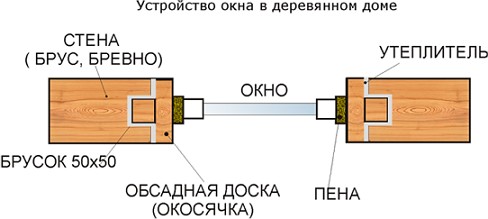

Unlike the installation of PVC windows in panel, brick and block openings, the installation and installation in a wooden house involves placing in the opening a window (casing) from a board and a beam section of 100x150 mm, which receives and distributes the load from the window structure with a double-glazed window.

need for a window

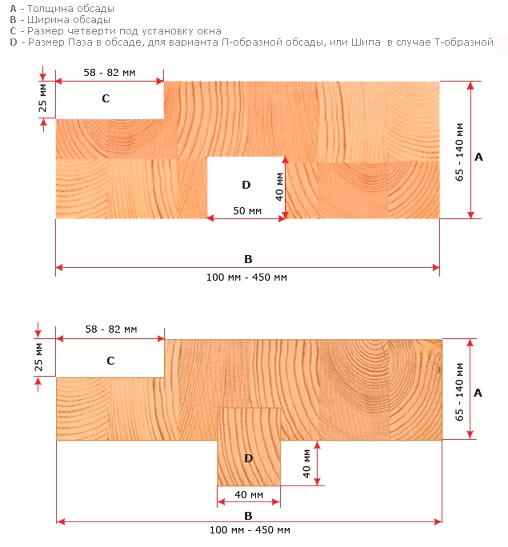

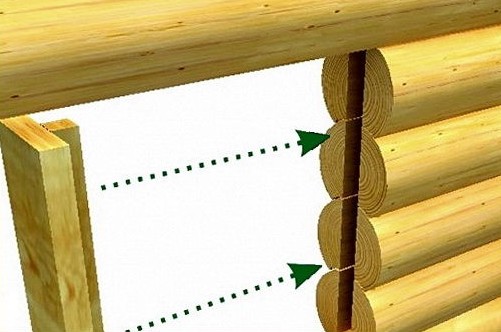

Let's tell, that a window of a wooden aperture distinguishes simple and complex. A simple window is made by sawing the grooves of the required section in the ends of the window opening with the subsequent blockage of the bar into the groove.

For a complex little window is characteristic sawing in the ends of the aperture of the sinus sinus, into which a flap with a groove is inserted. The technology of the window is laborious and is based on accurate calculations, careful preparation of the casing and groove.

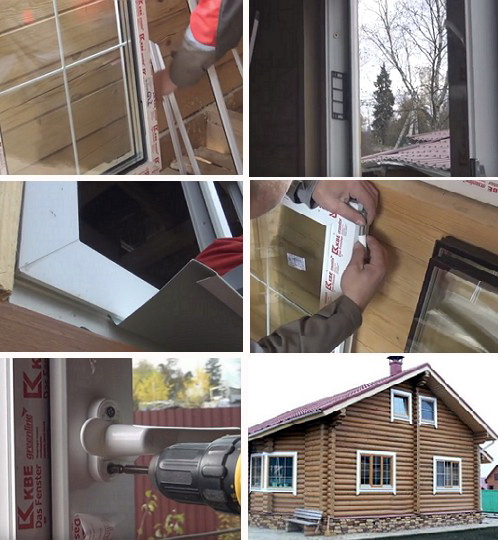

we install the installation of plastic windows with our own hands in the wooden house (step by step)

Installation of windows consists of the steps: creating a window and installing a frame structure.

Creating a window (casing)

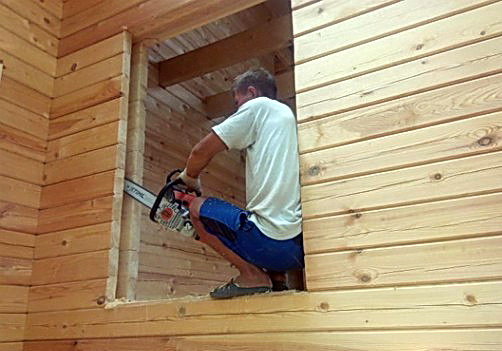

Step 1. In the wall of the wooden house, by size, cut out the window opening.

Step 2. We prepare the working beam and mark out the side wall.

Step 3. In the end (side) walls we cut the notch to the depth of the section of the beam.

Step 4. We heat the prepared bar into the formed opening of the wall and hammer in place, leaving a clearance of 5 cm above the casing board at the top.

Step 5. We prepare the casing boards and choose 1/3 at the ends.

Step 6. We milling the groove sample.

Step 7. We warm the inner side of the side casing with jute.

Step 8. We install in the ridge sinus depth of 5 cm groove of the lateral casing

Step 9. We fix the board into the beam with the use of a screw.

Step 10. We install the second side casing in the same way.

Step 11. Mount the top and bottom boards.

Step 12. We sew the jute insulator into the groove above the upper board.

Step 13. The groove is smeared with a sealant, we install the upper board and plant it in place.

Step 14. We grease the joints and fix it with a screwdriver.

Step 15. We heat the joint between the casing and the bar.

Detailed information on creating a window is provided in the video.

Helpful Tips

There are 2 ways to install a frame structure: with unpacking and without unpacking. Installation with unpacking of the double-glazed window consists in complete disassembly of the structure - they remove the glazing beads and the double-glazed windows, the sash is removed from the hinges and the frame is installed with the use of anchor plates to the wall. This method is most suitable for 3-fold heavy PVC windows to facilitate installation. The second method consists in fixing the frame to fixed fastening elements on the outer surface of the walls. The frame is suspended and fixed. Recommended for light single-sided double-glazed windows.

Installation of a frame structure without a window sill with unpacking of double-glazed windows

Step 1. We remove the glazing beads from the flaps and the pin

Step 2. We take out the double-glazed windows.

Step 3. Remove the film from the outside of the frame

Step 4. We glue the heat insulation tape to the end of the frame

Step 5. We insert the frame into the opening and expose the verticality and horizontality in the level.

Step 6. We fix the frame from the inside to the wall on the fastening elements.

Step 7. We set the tide in the groove and fix it on both sides.

Step 8. We fix the mounting tin with the mounting foam from below.

Step 9. On the leaf we install the lining.

Step 10. We hang the leaf and install the handle

Step 11. We lay out the plastic pads and install the double-glazed windows.

Step 12. We fix the shtapiki, starting from the top with a short and long sides.

Step 13. We foam the assembly seam.

The best advice on installing and installing windows in a wooden house is shown here.

A feature of the installation of windows in a brick house is to increase the width of the slope to 20 cm after the dismantling of the old one. In addition, for brick houses are characterized by wide windowsills for plastic windows, L to 40 cm.

Demountable dimensions of the opening is recommended when selecting components for plastic windows when installing plastic windows in a brick house (step by step).

Measures when installing PVC windows in a brick house (step by step)

Step 1. Remove the old window and level the walls of the opening.

Step 2. We make a control measurement of the overall dimensions of the opening.

Step 3. We install the window frame and fix it to the wall on the anchorage.

Step 4. We place a double-glazed window in an opening concerning deviations in the sizes

Step 5. We set the tide.

Step 6. Blow the gap between the frame from below with foam

Step 7. We hang the sash

Step 8. We install the window sill and expose the level with the creation of a gradient of 3 ° and the use of wooden wedges.

Step 9. The resulting cavity under the sill is blown out with mounting foam, and the surface is loaded for 10-12 hours.

Step 10. We install slopes.

Without jambs)))

According to developers, plastic windows installed in wooden or brick houses, given the impressive thickness of the walls and the capital structure, are maintained longer.