Any work related to the fastening or installation of building elements is faster and more reliable if the appropriate tool is used. The appearance of the stapler is due to the original office functions of the instrument. Just so, step by step, the stapler won recognition. Now, without its universal application simply can not do. How should I choose this tool?

Content

Types of construction stapler and scope

One of the many hand tools that can facilitate the work of the home master and improve the performance of the work done is a stapler.

Whoever at least once held in his hands a construction stapler, will appreciate its qualities and possibilities:

• Securing wire mesh

• use for office work

• fixing the upholstery

• Fastening the cable

• Strengthening of other building elements.

Simplicity of construction and ease of use of the tool allow to fix the synthetic film, cardboard, leather, and also other materials of insignificant thickness.

Therefore, to work in home workshops, this tool is simply indispensable.

There are stapler building:

• Mechanical

• electric

• Battery.

AT mechanical stapler, the main element is the spring, which, with the use of muscular force, is bent using the outer lever. The mechanics consists in uncoupling the lever from the spring when passing the end position. The spring unbends and clogs the bracket located in the clip of the stapler. Release the lever is the main link for feeding the new bracket.

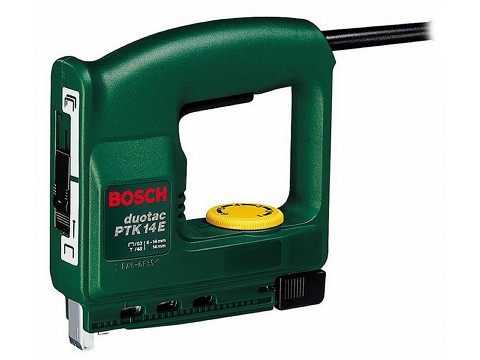

Naturally, in comparison with a simple mechanical tool, in a stapler construction electrical all work is done by an electric motor. Electric stapler has a more extensive set of working options. More elastic spring mechanisms allow you to get a significant impact force at the output, able to cope with a hard working surface. Power staplers electric can reach 1500 watts.

Electric staplers are completed by manufacturers of large consumables and additional working elements.

This is a universal tacker, which allows you to work with staples of different configurations and the ability to load staples from either side of the striker.

Rechargeable A construction stapler can be called a kind of electric stapler. Manufacturers produce staplers with lithium-ion batteries and nickel cadmium batteries. The working voltage of battery staplers reaches 18 V.

Naturally, electric and battery types of staplers are more expensive than mechanical staplers. However, before you start to choose the tool, you need to know in detail its principle of operation and design.

What is the principle of the stapler, and by what criteria is it preferable to choose it for later use?

The design and operation principle of the stapler

The principle of work is concluded in the simple structure of the shock mechanism. Something in the work of a stapler is similar to the device and the operation of a gun. The same weighty handle that comfortably lies in the palm of your hand, the same "lethal force" - just pull the trigger once and the clamp firmly fixes the material to the work surface.

The twisted spring spring of the mechanism, which carries out a short-term kinematic "shot", is cocked using a slight muscular force. By pressing the trigger of the stapler, and taking the inner lever to the extreme position, the striker is released. Bojek in working condition, according to the laws of physics and kinematics, pulls out a "shell" - a bracket from the cage and directs it to where the stapler moving vector is directed.

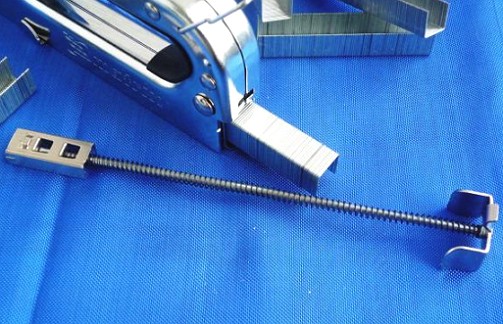

Similarly to the clip of the pistol, the staples are placed in the feeding store. Staples for the construction stapler are fed into the device. Staples are stored glued together in long packs and are the main tooling tool.

In the design of the stapler, the type of impact mechanism is of particular importance.

type of impactor

The type of the mechanism of the impact stapler depends on the type of the spring. There are the following types of springs:

• torsional

• Spring.

A torsion spring or a coil spring requires considerable applied forces, but the yield of a stapler with this type of spring is noticeable.

The spring or leaf springs are preferably used in professional models. Spring spring is easier and easier to "cocked", providing a small return, but the cost and price of the stapler will be much higher than with a torsion spring. By the way, to neutralize the kickback of the stapler use a variety of damping pads on the handles, as well as winning constructive solutions.

In this case, all the released energy is distributed evenly from the handle of the instrument to the person's palm. Therefore, the most useful advice when choosing a stapler can be called the choice of a tool with a low level of noise during work and low returns. These parameters emphasize the manufacturability and quality of the tool.

Thanks to the spring resistance and even distribution of load, a good construction stapler can work for a long time without feeling tired hands.

It is recommended that when selecting a tool, pay attention to the "grip angle" of the handle, which shows how far the system lever is removed from the tool body. In practice, the smaller the "angle of capture", the more comfortable the tool is.

staples

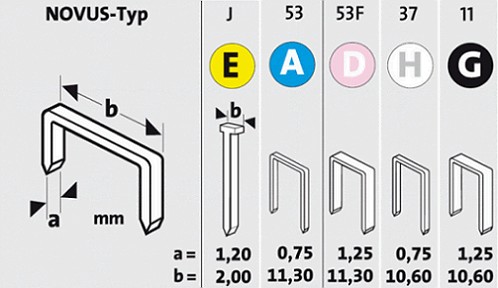

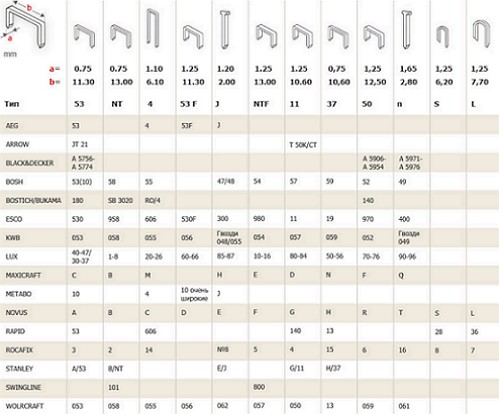

Work staples for a stapler are characterized by certain parameters, which should be taken into account when choosing a tooling. These are the parameters:

• Staple material

• sharpening of the ends

• the size.

Staples are made of steel or brass, the type of fabric of which can be determined visually by color.

Sharpening the ends and the size of the staples greatly facilitates their entry into the working surface. The most popular is the U-shaped bracket, with a different length of legs, a certain thickness and width.

The classic version of the sharpening of the ends of the staples - the legs are sharpened from the outside or inside, providing good piercing. There are clerical and industrial types of staples. Standard staples are the following sizes: 10, 24/6, 24/8, 26/6 and 26/8,

where 24 is the staple number, 8 is the length of the stalk.

The hardware block, in which the staples are assembled, must have a uniform structure and should not decay or break. The outer adhesive strip should be invisible and glue the staples only on one side.

For staplers electric use special staples, which are made of a more durable material and withstand a more powerful short-term impact.

Useful tips when choosing a tool

We will not hide that the main criterion for choosing an electric stapler is its "quick-fire" abilities. Therefore, it is not unreasonable to pay attention to the following characteristic of the instrument, namely the number of pulses per conditional time.

Let's say that this parameter, depending on the model, can be in the range of 20 to 30 rounds of shots per minute. The highest progress, in terms of rapidity, was achieved for the battery tool

BOSCH PTK 3,6 V.

Like any tool, a stapler must have a certain degree of protection. To protect against the possibility of electric shock, plastic covers are used, as well as lining on the handle. When choosing a tool, it is better to give preference to rubberized non-slip pads.

Manufacturers of the tool have taken care of the internal insulation of the electric motor: the motor windings and the power cord have increased insulation. Choose a tool with a long supply cable. A long cable of up to 5 m of electric stapler increases its ergonomics.