With the word "monolithic foundation", the imagination draws a solid and reliable construction of high-quality concrete, the quality of which is not lower of concrete in Ivanovo, capable of withstanding any load. In which cases is it more expedient to build a monolithic foundation and how to make concrete pouring?

Content

In which cases is it preferable to erect a monolithic foundation

The most popular type of foundation was and remains monolithic. Houses and structures, built on a monolithic foundation with strict compliance with the technology of installation and pouring, are reliable and durable.

What characteristics distinguish a monolithic foundation?

Without exaggeration, the following qualities of this type of foundation can be noted:

• operational

• constructive.

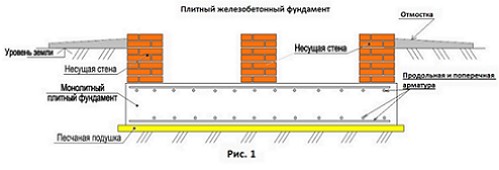

Structurally, the monolithic foundation is a surface made of reinforcement and filled with concrete.

This type of foundation is preferred for soils with insufficient strength with a high water saturation coefficient characterizing the near location of groundwater. For "problem" soils, namely low-bearing and peaty soils, a monolithic foundation is the main type of bearing structure. We will discuss right away, the cost of the foundation is quite high, therefore, in cases where the erection of another type of foundation is unacceptable is almost unacceptable, a monolithic supporting structure is preferred.

Methods of building a foundation

According to the method of erecting the foundation for the objects under construction, the following types are distinguished:

• shallow

• Deep deep.

The depth of the shallow foundation is 0.5 m. Unlike the basement, monolithic substrates are rigidly reinforced, along the perimeter of the entire supporting structure.

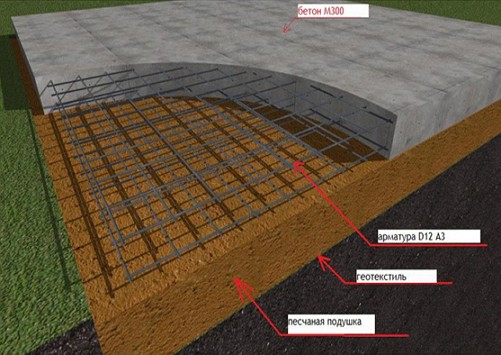

The foundation is grounded using reinforcing bars of ribbed class A3. The construction is made of metal, made of reinforcement of this class, has good adhesion to concrete. Thus, a rigid connection is achieved, preventing the destruction of the supporting structure over time.

Calculation of foundation

Calculation of the foundation begins with the design of the load, namely the assumed load, which theoretically lies on the ground and foundation. The design load consists of constant and time parameters. Constant load parameters are the weight of the construction structure and the main performance characteristics.

Temporary loads include weather conditions that include wind force and snow thickness in winter. The projected load on the foundation is calculated approximately. The main task of calculating the projected load is the condition of uniform load distribution on the foundation. Then the weight of the house and all its building elements is determined. The next calculation parameter is the determination of the construction area of the house and the weight.

For this, the weight of the foundation must be added to the indicators of the weight of the house or building. The depth of the foundation foundation depends on the characteristics of the ground and in most cases is from 350 to 500 mm.

Then, the ground resistance is calculated. For a favorable condition that the foundation "suffered" the construction, it is necessary to fulfill the following condition stipulated by the building codes and rules: "the specific load on the ground must be less than its design resistance."

A 20 per cent ratio of the plantar load to the design resistance is allowed. Based on the calculated parameters of the foundation, the amount of concrete is calculated. Calculated parameters for calculating the amount of concrete slab monolithic foundation, the following data are required:

• plate thickness

• area occupied by the plate

• basic parameters of the stiffeners.

Technology monolithic foundation

Monolithic foundation is erected step by step.

Before the foundation works are started, a geological and hydrogeological survey of the soil is carried out, the purpose of which is the subsequent calculation of the thickness of the sand and gravel cushion.

The main stages of erection of a monolithic bearing structure are:

• arrangement of foundation ditch for foundation

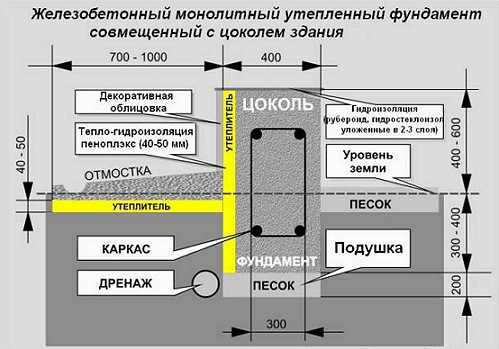

• Waterproofing and draining the bottom of the excavation

• Reinforcement frame assembly

• reinforcement with cells

• erection of formwork from the board

• pouring of ready-mixed concrete.

Work on the construction begins with excavation - excavation and backfilling of the sand cushion, as well as binding and marking the foundation in the axes. At this stage, drainage of the bottom of the excavation and drainage of groundwater is carried out. Waterproofing for foundation monolithic is done in two layers.

Distinguish the following types of waterproofing monolithic foundations:

• lubricating

• okleychnuyu

• Impregnation

• Mastic.

Waterproofing coating is carried out by applying rubber and rubber mastics to the surface.

Oak is made by a special roll film on the prepared and cleaned surface.

Impregnated waterproofing is a composition of bitumen, synthetic resins and water glass. The applied hydrophobizing composition is absorbed into the microcracks and pores of the foundation, creating a protective film.

Mastic insulation is hot or cold bitumen-rubber mastics with an increased coefficient of stretching. A layer of rubber-like waterproofing excellently protects the bottom of the excavation from the corrosive effects of chemicals from the ground.

Regardless of the type of waterproofing chosen, the foundation must be isolated, eliminating its destruction.

After the waterproofing, reinforcement is made. The reinforcing cage is made of reinforcement A3 with a cell pitch of 25 cm. Then the formwork is built from the board and only then can the concrete be poured.

For a monolithic foundation, high-quality 250-400 concrete is used. Concreting is carried out by layers. During the concreting process, the vibration process is performed.

For these purposes, a powerful concrete vibrator is used, which allows to remove air bubbles from the total mass and performs compaction. The resulting monolithic structure undergoes development within 2-3 days. The surface is wetted and insulated. After the final drying of the monolithic structure, the formwork is removed and the foundation is ready for the erection of the walls.