Starting to work with new building materials, owners of private homes thoroughly study the recommendations of manufacturers at work. And it is right! Any material intended for the waterproofing of the foundation requires the study of its properties and capabilities. By mastering the technology of roll-on waterproofing, it is possible to further protect any work surface.

Content

About the importance of waterproofing works

An important measure, without which it is impossible to build a quality foundation of any type, is waterproofing.

For the protection of the foundation surface, there are several types of waterproofing:

• coating (mastic)

• two-layer coating

• roll or backboard

• deep penetrating.

The choice of type of waterproofing works is based on the technology of application or styling. The only thing that unites the technology of laying or applying is the creation of a continuous waterproofing layer. The most demanded and technological method is the waterproofing of the foundation roll.

Helpful Tips

Modern applied waterproofing materials are a combination of a glass-fiber or polyester base with a bitumen-polymer binder, a thermoplastic and a filler. The protective layer of roll waterproofing can be coarse-grained, fine-grained, and polymer film. The leader of roll materials is waterproofing technonikol.

Rolling waterproofing: what types exist and how to apply

kinds

An actual and popular way to protect the foundation of a private house is a roll waterproofing, the essence of which is to create a waterproofing carpet. There are the following types of waterproofing roll:

• pasting, using mastics and roll materials

• fused, using the method of heating and melt the polymer layer

• with the help of membrane membranes of diffuse composition.

The most popular method of application is a self-adhesive roll waterproofing.

How to lay the roll waterproofing

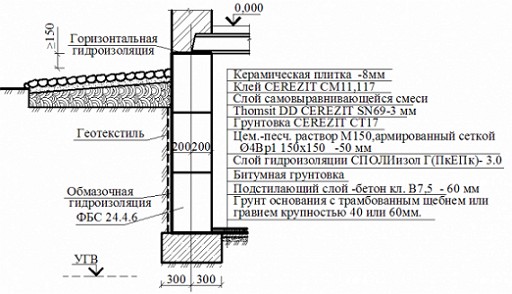

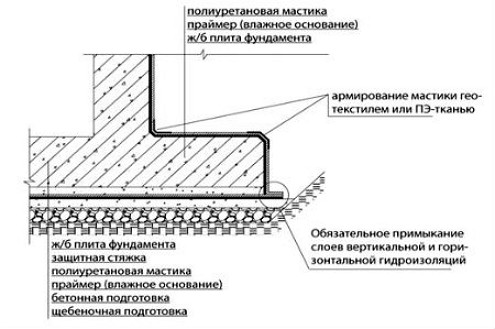

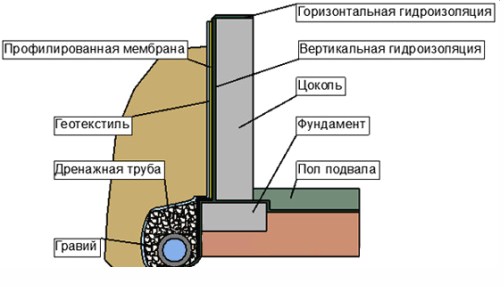

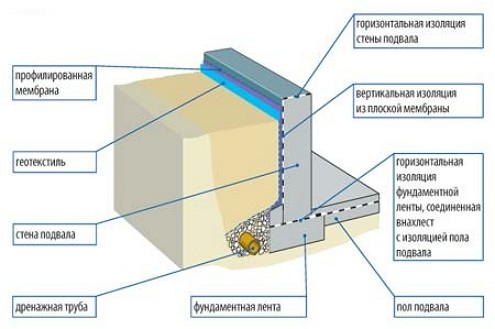

Depending on the spatial orientation of the application of the material on the surface, vertical and horizontal waterproofing of the foundation are distinguished. For each spatial direction of the waterproofing, there is a certain technique and application technology, under which the foundation acquires a reliable waterproofing layer.

Waterproofing roll is made using polymer, bitumen and polymer bituminous materials in 2 or more layers of laying in the direction of the horizontal or vertical surface.

Technology of waterproofing works of the foundation with roll materials

The technology of waterproofing works consists of the stages:

• preparation of the working surface for application

• primer coat application

• preparing and cutting a roll for styling

• laying the first layer of roll waterproofing

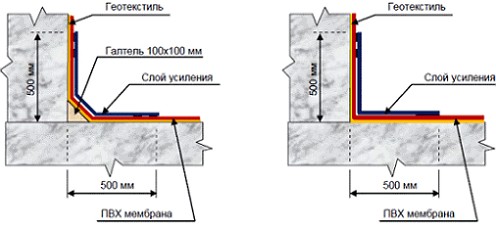

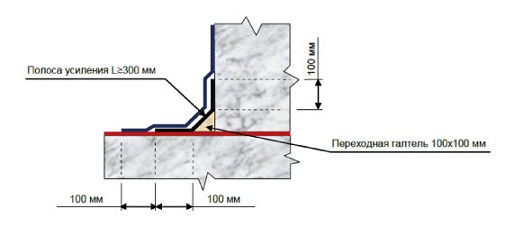

• laying waterproofing in the corners

• application of the second layer.

vertical waterproofing

Before laying roll waterproofing materials on the surface, the vertical working base is prepared: remove traces of foam, grease and bitumen. Fix cracks, potholes and other defects of the concrete surface. In the case of heavy contamination of the concrete foundation foundation, a layer of geotextile is allowed.

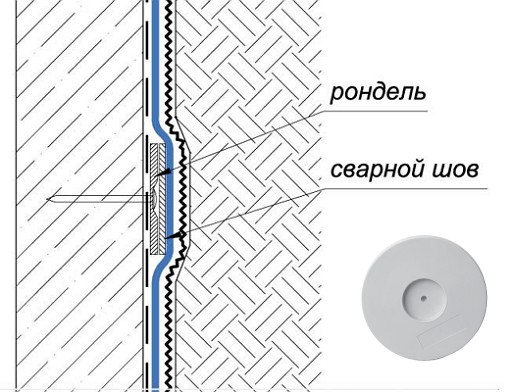

Then, at the inner corners of the foundation, fix the fillet or make corners using a waterproofing tape or mastic. Further on the surface of the foundation set special PVC Rondel - plastic construction, designed for ease of fastening and mounting the roll during welding and fusing.

Rondeli placed horizontally with an interval of up to 1.5 m and vertically up to 2 meters. Cutting of the roll material is made taking into account the allowance on the welded seam (10 cm). The material is attached using a construction hair dryer, welding joints of strips of roll material with double seams. The gap between the strips can reach 20 cm.

Rolled materials with a smooth inner layer are glued to the surface using glue. The glued surface of self-adhesive waterproofing is rolled with a heavy roller of Teflon.

The studded or profiled waterproofing material does not need additional protection.

For example, this is how the application of a vertical waterproofing with the use of the Tefond membrane with the functions:

• Effective drainage, drainage or dewatering

• protection of the main waterproofing layer against mechanical damage

• additional waterproofing when creating an air gap.

horizontal waterproofing with welding

When carrying out a horizontal waterproofing, the roll-up preparation of the substrate is given special significance. It must be remembered that with horizontal waterproofing with their own hands, the material adheres to the base of the concrete. Any point force or unevenness of the layer can damage the material.

Therefore, in some cases, a backfill is used, the purpose of which is to damp the possibility of damage to the layer. For this purpose the site is prepared, leveled and labeled. Then they are filled with sand, followed by leveling and tamping. After the tamping of the sand cushion, the geotextile layer is laid.

Geotextiles must be chosen with a material density of 400 g / m2. Laying is performed with overlapping of strips up to 15 cm, followed by welding with a special apparatus. At the junctions and joints of the strips, the welds are cleaned. The final stage of horizontal laying is rolling the waterproofing layer with a Teflon roller.

We make quality control of welding seam

At the end of the welding of the roll waterproofing, quality control is carried out. For monitoring use a special device and a compressed air compressor. The injected critical pressure from the compressor to the weld region must be maintained during the control time.

A qualitative welded seam and properly laid waterproofing must undergo a "test drive". If an unsuccessful attempt is made, it is necessary to sincerely regret the spoiled materials and the time spent on laying not according to technology.

We recommend that you familiarize yourself with the video, which details how to apply waterproofing yourself.