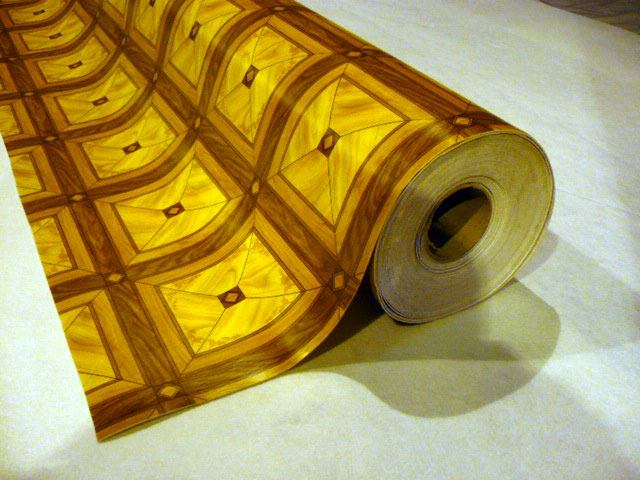

Linoleum is the most common floor covering due to its low price, ease of maintenance and durability. This kind of flooring was invented in the nineteenth century and was originally made entirely of natural ingredients. The name "linoleum" was "linum" - flaxseed and "oleum" - oil. Modern linoleum is not so natural, but it is distinguished by a great variety of types and colors. For us, modern linoleum is all the variety of different roll-up floor coverings made of polymer.

Content

Types of linoleum

If we want to divide modern linoleum into specific groups of binding material, we will end up with the following:

- Natural linoleum

- Polyvinylchloride (PVC)

- Glyftal (alkyd)

- Colloxylin (nitrocellulose)

- The rubber (reel).

If we consider linoleum in accordance with the European classification of floor coverings, then figure two on the label will mean a linoleum suitable for use in living quarters, a figure of three in office, and a figure of four in linoleum for industrial premises. And linoleum for office or industrial premises is not intended for use as a floor covering for living quarters, since it can exude a peculiar smell and emit some harmful toxins that can affect the health of a person who has been in the room for a long time in the room where he is laid.

The choice of linoleum for home

The most common type of linoleum is PVC (polyvinyl chloride) linoleum. It is made either on foamed or fabric, or on heat-sound-insulating non-woven basis, and on a single- and multi-layered substrate or generally baseless. When buying and laying PVC linoleum, except foamed, with a base of fiberglass, it is necessary to take into account its substantial shrinkage (even up to two percent). If you buy such a linoleum for residential, sleeping and especially children's rooms, then take into account the fact that it has a certain specific, disappearing with time, odor.

For rooms with increased terrain (corridor, hall and kitchen), in order for it to last you for many years, it is better to purchase linoleum with a thick and dense upper PVC layer (0.3 mm).

Choosing a substrate (the lower layer of linoleum, its base), pay attention to the material of which it is made. For example, a natural felt pad - warm, as well as noise and heat insulation. If the floor in your house has a wooden floor with flaws, the floorboards fail, then the substrate should be thicker, preferably foamed. This base is suitable for rooms with high humidity (in contrast to felt).

Also take into account the advantages of glyptal linoleum, manufactured on a fabric basis, as it has heat and sound insulation properties better than PVC linoleum. When buying such a linoleum, keep in mind that over time it decreases slightly in length, but widens in width.

Selection of linoleum for non-residential premises

For non-residential (technical, production, office) premises, colloxylin (nitrocellulose) linoleum is often chosen. It, produced without any basis, a single-layered, rather thin material, characterized by high moisture resistance and elasticity, but increased flammability.

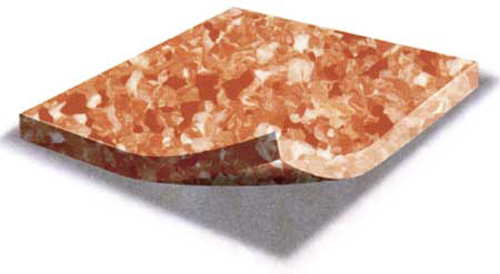

If a stronger, thick, two-layer material with a base is required, we advise you to pay attention to the rubber linoleum, the so-called "reel".

Its lower layer (lining), as a rule, is made of rubber, so this linoleum has increased water resistance. In the composition of the face layer - synthetic rubber, various fillers and pigment. Thanks to such components, it is very elastic.

Homogeneous technical linoleum is a unique homogeneous material made of PVC and dyes.

The uniqueness of this linoleum is that the drawing, which is located on it, is not directly applied to the surface, but penetrates through it to the full thickness.

Thanks to this feature, this linoleum practically does not wear off with time and is indispensable in the rooms with increased cross-country capacity (hotel halls, cafes, reception rooms, etc.).

For industrial premises I choose linoleum with a thickness of the top layer not less than one millimeter.

Features of laying linoleum

And, in conclusion, I want to note that even the highest quality linoleum will quickly deteriorate and lose its appearance due to improper laying on unprepared floor.

The main principle in linoleum flooring is the purity and ultimate leveling of the floor. In this important uneasy work can help an ordinary household vacuum cleaner. When laying the floor covering, after completion of each stage, it is necessary to vacuum the floor with special care, avoiding even the slightest falling of dust particles under the linoleum (which can subsequently give a swelling), and all the work will be in vain. Even before the beginning of the laying works, in the process of preparation, it is necessary to level the floor as much as possible, smoothing even small irregularities and roughness. To achieve the most leveled surface, the work uses a self-leveling solution, poured over the cement screed.

Below we present a video explaining the peculiarities of laying linoleum in an accessible style, which you can do in your house with your own hands, using the tips given here.