The newest technologies of thermal insulation of private houses and cottages consist of polyurethane spraying (in this work it is good to use screw compressor to feed the polyurethane cloud to the upper tiers). In addition, as a thermal insulation, we can offer a simpler version of insulation with expanded polystyrene, since this is the ease of use and the relative cheapness of the insulation.

Content

Properties and field of application of expanded polystyrene

Making heat insulation work in a private house, I always want to hope for a positive end result, namely, quality insulation. With a heat insulation of the house, a simple and relatively cheap insulation - styrofoam.

The appearance of expanded polystyrene in the construction industry, we owe the best promising developments of the domestic technology of styrene copolymers. What is a heat-insulating material for expanded polystyrene? Obtained as a result of foaming of a low-boiling liquid, expanded polystyrene is a building material made of fine-mesh granules. The granules, which are caked in the process of production, have a microporous structure around which voids are formed.

Therefore, the main mechanical properties of the material are:

• Thermal conductivity

• water absorption

• water vapor permeability

• frost resistance

• Long service life

• Biological resistance to solvents.

It is thanks to these properties that the demand for insulation of the house with polystyrene foam outside and inside was obtained. The only unfavorable factor of ubiquitous use of expanded polystyrene is its fire hazard. Styrofoam is manufactured in the form of finished slabs of various sizes and thickness. Plates can differ in performance characteristics. Therefore, you just need to know the capabilities of this material, carefully studying its characteristics.

The main characteristic of expanded polystyrene, which gave the building material a bright future, is its thermal conductivity.

thermal conductivity

Heat-saving properties of expanded polystyrene plates provide insulation with extruded polystyrene foam. Recall that the thermal conductivity of the plates can be in the operating range from 0.037 to 0.044 W / mK. For comparison, the thermal conductivity of the following materials is:

• wood and expanded clay - 0,12 W / mK

• brick - 0,7 W / mK.

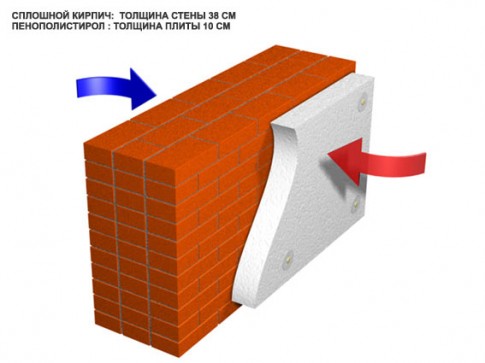

According to standards, a significant level of energy saving can be achieved with expanded polystyrene 12 cm thick, wood - 45 cm, and brick walls - 2.10 m.

By the way, not many people know how to distinguish a styrofoam from expanded polystyrene by their own hands. Learn to understand this video.

How to insulate the house with expanded polystyrene

It is possible to insulate the house with expanded polystyrene outside and inside. And the process of insulation can be exposed: floor, foundation, walls, facade.

Thermal insulation of a wooden house with expanded polystyrene will not be technologically different from the insulation of brick or concrete wall surfaces.

basement warming

Warming of the foundation with the use of expanded polystyrene is presented in this video.

external wall insulation

The external type of insulation of the walls of a private house can be confidently called the most popular. It is possible to insulate the house from the outside with expanded polystyrene foam for brick, concrete and wooden walls.

The main advantage of warming the walls of the house from the outside in comparison with the warming of the house from the inside is the absence of influence of the thickness of the heat-insulating layer on the useful area. Therefore, you can safely use sheets with a thickness of 90 mm or two layers of 40 mm.

It is noted that external insulation with expanded polystyrene extruded provides the possibility of saving heat to 50 percent, thereby reducing the cost of internal heating.

The process of thermal insulation will consist of technologically different preparation of the working base.

Before starting to perform insulation work, it is necessary to prepare wall structures for laying.

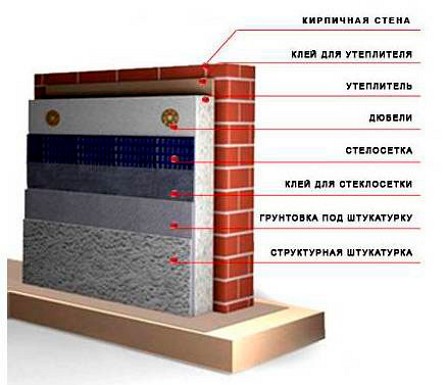

Wall surfaces are cleaned of residues of dirt, lime, cement spray using brushes and spatulas. Then the working surface of the wall structure is treated with a deep penetration primer. For the installation of insulation plates for brick and concrete walls, special glue and dowels are used. After the final drying of the primer layer, the adhesive solution for the expanded polystyrene boards is prepared.

Application of finished glue is carried out with a notched trowel along the perimeter of the plate and in several points of the center.

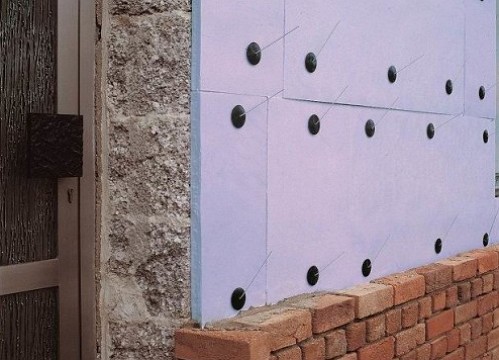

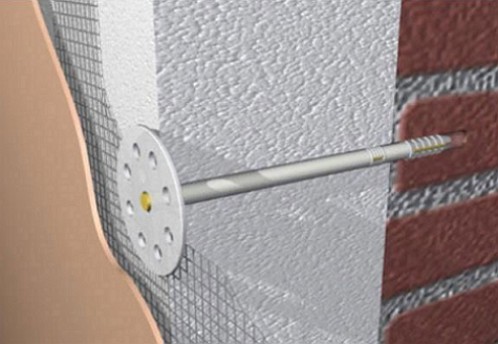

Then the slab with the applied adhesive solution is pressed against the wall and pressed. After fixing the slab of expanded polystyrene on the work surface for additional reinforcement, dowels are fastened to the corner parts of the expanded polystyrene plate. For fastening use dowels with a considerable length of the working body of the fasteners.

It is recommended to choose the length of the dowel, taking into account its penetration when installing in a wall surface of 4-6 cm. After the plates have been installed, a polystyrene surface is primed. To make the strength stronger, reinforcing reinforcing mesh is used.

The story about the advantages of expanded polystyrene with the thermal insulation of a private house will be incomplete if you do not focus on modern technology of fixed formwork.

Particularly popular with the insulation of private houses was the technology of warming the house from a fixed formwork made of expanded polystyrene.

Non-removable formwork technology

When building walls from expanded polystyrene blocks, the technology of non-removable formwork is applied. Due to the tremendous mechanical characteristics of cellular polystyrene foam, the fixed formwork is guaranteed to withstand the pressure of concrete during the construction of a monolithic one.

In addition, formwork blocks made of expanded polystyrene have a negligible weight, which allows you to abandon the expensive services of specialized equipment and produces works with your own hands. Stability of the mechanical characteristics of expanded polystyrene allows the use of fixed formwork blocks when building houses for "problematic" areas. For reference: the density of expanded polystyrene in the formwork product is fixed to 38 kg / m3.

It is a sufficiently high density of the material that makes it possible to decorate outside and inside houses for all types of finishing materials. The house, built from elements of fixed formwork, provides the same heat savings as a brick house with a wall thickness of 2 m. Using the shuttering blocks, it is possible to achieve energy saving all the more, especially since the density of the blocks 1x1 m in size is 10 kg / m3.

With the observance of the technological process of erection of a non-removable formwork, the bearing capacity of a single unit allows the concrete to be poured into a wall 3 m high. And if you add excellent thermal insulation characteristics of expanded polystyrene, then there is nothing better to warm the private house.