Conduction of electric welding work can not be carried out without a special welding machine. What are the criteria for choosing this device, and what qualities should it characterize best?

Content

If you do not have a welding machine

The most wanted tool for a home master can be called a welding machine with confidence. With the skillful use of a welding machine, a lot of useful work can be produced, requiring the use of qualified welding.

It can be a mix of reinforcement intended for pouring a foundation or attaching metal elements. Versatility and fine work with a welding machine allows you to work in uncomfortable or difficult places. And with the use of this tool, not only welding works are carried out. By applying welding, it is possible to cut the metal or jammed screw connection.

However, the scope of the welding machine is quite extensive. Therefore, before choosing a tool for the needs of the home master it is necessary to determine the range of tasks to be solved.

Modern welding machine

In comparison with the honorary electric welder of the 5th category of the last century, carrying an awkward and antediluvian welding machine with a self-made transformer, the modern owner of the machine has many advantages. Let's name just some of the obvious advantages:

• Welding in any spatial planes

• possibility of welding various steel grades and non-ferrous metals

• Easy and convenient transportation of the device.

Therefore, a modern welding arc welding machine is a welding inverter. What is attractive for a welding inverter for a home workshop? Of course, this is a modest overall size and weight. A small welding machine can be comfortably hung on the shoulder and go into welding work for neighbors in the country. Yes, and the energy source of the welding machine of the NEXT generation is a high frequency current with a denomination of tens of kilohertz.

By the way, at the same time welding is carried out with the help of direct current, providing an excellent quality of the seam. Inverter welding machines consist of the following elements:

• Rectifier

• transformer

• converter

• control schemes.

The welding inverters operate on an accessible element base - powerful power transistors manufactured using innovative IGBT or MOSFET technology.

In addition, welding inverters can be included without excitement in any household outlet. Inverter units comply with the requirements of the European standard EN 61000-3-12, which regulates certain restrictions for power grids and equipment connected to them.

What is needed for arc welding

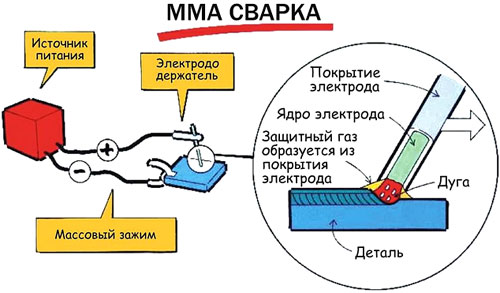

One of the methods of welding, in which an electric arc is used in the production process, is arc welding. The process of heating and melting the metal for this type is achieved due to a significant heating temperature of the electric arc and can reach 5000 degrees. With the use of welding apparatus for manual and automatic arc welding, welding of metal structures is performed.

Therefore, the welding machine is most in demand for daily work related to welded operations.

In direct dependence on the degree of mechanization, the following types of welded work are distinguished:

• manual electric arc welding (MMA)

• semi-automatic and automatic arc welding (MIG / MAG).

The process of welding works depends on such factors:

• Starting the ignition and maintaining the arc length

• correct electrode manipulation when creating a weld

• the end of the electrode movement on the working line of the seam creation.

Therefore, regardless of the type of welded device, the technology of electric arc welding remains common.

Arc welding technology

The manual technology of electric arc welding assumes the work on the formation of a quality welded seam without the use of any mechanisms. When semi-automatic arc welding, work is carried out to feed the electrode wire into the work area, and then standard manual welding is performed. In automatic arc welding operations are mechanized:

• Excitation of the electric arc,

• maintaining a stable arc length and moving the arc along the main weld line.

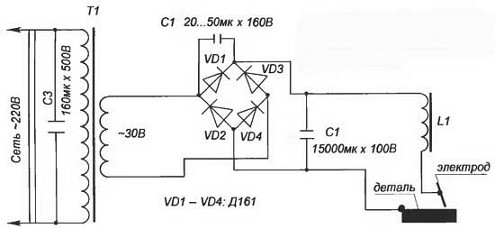

A constant or alternating welding current is applied to the point of formation and maintenance of the arc. Therefore, in the arc welding system, a welding transformer or inverter is used.

How to make a choice of the welding machine will help the proposed video.

Under the influence of an electric arc, the rod - electrode and metal of the welded product melts. The resulting electrode metal from individual droplets passes into the state of a "welding bath". In the weld pool, molten metal is mixed with the metal of the welded product.

The slag formed in the process of welding floats to the surface. The result of melting the electrode is the formation of a characteristic gas atmosphere that pushes the air out of the welding zone and prevents the possibility of its subsequent interaction with the metal.

As the electrode moves for arc welding, the metal in the weld pool crystallizes, forming a reliable weld seam. Thus, the result of electric arc welding is a seam formed from a layer of solidified slag.

What kind of electrodes are needed for welding

The following types of electrodes are used for the production of welded work during electric arc welding:

• for traditional household works

• for welding of critical structures.

For ordinary domestic work, use electrodes of the brand MR-3, ANO. The diameter of household electrodes is from 2 to 4 mm. To weld responsible designs, preference should be given to the SSSI brand. The quality of welding and the strength of welded welded electrodes of the SSSI brand are much higher. By the way, the basic rule of choosing electrodes: the thicker the piece, the thicker the electrode and the higher the welding current.

However, specific parameters of the working current of welding and the thickness of the electrodes are selected experimentally during the process.

How to choose electrodes for electric arc welding will help video.

In addition, it is necessary to take care of welding cables and electric holders with quick-detachable fasteners directly to the device. To interface with the welding machine, two cables are required, equipped at the ends with connectors for reliable attachment to the work piece.