Before the construction of a new house in front of the owner, the question inevitably arises: what material is best to cover the roof? It is difficult to give a unambiguous answer, because everything depends on the climatic zone, the requirements for the material characteristics - heat and sound insulation, color, weight, and, most often, the decisive role - cost. Considering all possible options, one can not ignore such an interesting roofing material as bitumen shingles. It is modern, reliable, durable and beautiful. Bituminous shingles are often called roofing tiles, soft roofing or shingle roofing.

Content

What is shingles?

This material consists of several layers. At the core is a strong fiberglass, covered with a layer of bitumen impregnation. Due to impregnation, this roofing material is resistant to temperature changes and does not allow water to pass through.

The upper layer of bituminous shingles is a colored powder from mineral rocks. In addition to aesthetic function, powder provides additional protection against direct sunlight and precipitation. On the back side, each layer of tile has an adhesive base for a more reliable and hermetic attachment to the base of the roof.

If compared with other roofing materials - metal, ceramic tiles and slate, soft bituminous shingles benefit from:

- A small weight - no massive truss construction is required.

- Flexibility - this material is ideal for roofs of complex shape.

- Excellent thermal insulation characteristics - savings on insulating materials and heating.

- Minimal amount of waste.

- Not bad soundproofing properties.

- Durability.

- No need for additional care - the soft roof does not need to be painted and cleaned from lichens.

- Low electrical conductivity - soft roof does not require earthing.

However, if you decide to choose this type of roof, you need to take into account a number of significant shortcomings:

- High combustibility of the material. Bitumen shingles can ignite at temperatures above +100 degrees Celsius.

- Relatively low resistance to mechanical stress. Moving on the soft roof, you must be careful, as it can burst or move.

- Sufficiently high material cost per 1 sq.m.

Installation of shingles

Negligence in the work with bitumen shingles is inadmissible, during installation it is necessary to strictly adhere to the technology. If, of course, you want to have a reliable roof of bitumen shingles above your head.

Installation of a soft roof occurs in several stages:

- Installation of the base for the roof.

- Setting the backing layer.

- Mounting of valleys, cornices, ends.

- Laying of shingles.

- Fitting the abutments.

- Laying the roof tiles on the roof.

base installation

As a basis for laying a soft roof using a wooden crate, which can be either solid or latticed. For the installation of a solid structure, moisture resistant plywood, chipboard, and edging boards are used. If it is planned to make a lattice construction, then an edging board of coniferous rocks 2-2.5 cm thick is suitable. The material for the base is fastened to the rafters with usual nails or self-tapping screws. During the installation of the battens it is necessary to leave a gap of 2-3 mm between the boards, plywood or chipboard panels. This is necessary to compensate for the deformation of the material during the drying process. The gap can not be left only if the wood is completely dry and subjected to technical treatment. It is not superfluous to use antiseptic impregnation, both for rafters and for the base of the roof.

Important point: before starting the installation work you need to calculate the step of the rafters and the thickness of the material for the crate. For example, if the step between the rafters is 60 cm, then the thickness of the material for the substrate should be at least 2 cm. With a step of 90 or more centimeters, the material for the battens should have a thickness of at least 2.3 cm.

roof ventilation

Most often, the roof covered with bitumen shingles is ventilated by the ridge, which is laid on the ribbed profile. However, the bandwidth of such a design may not be enough. In such cases, ventilation elements are mounted on the roof. They are a ribbed profile that is fastened to the base of the roof, observing a step of 2 cm. The profile is nailed to the base after the tile sheets are laid on the roof slopes. Calculate the area of ventilation for the roof is not difficult. So, if the roof slope has from 15 to 40 degrees, then the ventilation area will be a private of the total roof area and 300. So, let's say that the total roof area is 60 sq.m. at a slope of 30 degrees. The cross-section of the ventilation element is 258 sq. M. cm.

Calculate the ventilation area: 600000/300/258 = 7.75. For accuracy, we round up to 8 - that is, for this area of the roof, eight ventilation elements are needed. If the skate slope is 41 to 80 degrees, the ventilation area is calculated as the private roof area and 600. The number of ventilation elements for the ridge is half of the amount required for the skates. In our case this is 4 pieces.

backing layer installation

The main purpose of the lining layer is to prevent moisture from entering the house if the tile layer is damaged. If the slope of the roof slopes is equal to or greater than 18 degrees, the layer of waterproofing must be located parallel to the cornices and the end edges of the roof. It is in these places that leaks occur most often. Therefore, the backing layer must be mounted no less than 40 cm from the edge, and even better to bring it to the very facade of the building. In the waterproofing also needs a skate. The layer of waterproofing material is laid not less than 25 centimeters from each side of the ridge.

If the roof slope is from 12 to 18 degrees, the backing layer is mounted over the whole roof area. Begin its laying from below, gradually moving upwards. The edges of sheets of material overlap with each other by several centimeters. To the base the insulation sheets are fixed with special galvanized nails with an increased cap. Nails are slammed every 20 centimeters. If the roof has overhangs, they need to be reinforced with special metal slats.

They are packed over the ends and cornices after laying the waterproofing layer. Fasten the bars with the help of roofing nails, which are clogged with a step of about 12 cm. After that, self-adhesive tiles are laid on the cornices and the end parts. Before starting the installation work, the protective film is removed from the tile, after which it is glued along the whole length of the cornices. The tiles are additionally fastened with nails.

In case there is such an element on the roof as the endowa, then it is necessary to lay a special carpet to make a continuous trough without cracks and joints. The carpet is fastened on both sides of the valley, the edges are treated with bituminous mastic.

Very often when laying the roof shingles, the roof color is not uniform, the roof has a different shade. This is because different shingles from different packages can have their own shade. To avoid such trouble, it is necessary to use the material simultaneously from several packs, evenly distributing the shingles of different shades.

shingles

Lay the tiles begin with the middle of the slope, from below the center of the cornice. Stacking is made vertically, in rows from the center, moving to the edges of the stingrays. The first row is laid in such a way that the gap between the cornice and the bottom edge of the bituminous tile is obtained. The extreme part of the upper row is often cut off - this results in a beautiful pattern and overlapping of the bottom row. If necessary, the shingles can be cut off along the edge of the pediment. The cut location is treated with bituminous mastic.

When installing the bituminous shingles with your own hands, remember the need for its additional fastening. Sheets are fastened with nails, at the same time you have to fasten two rows of tiles simultaneously - by hammering a nail into one row, you need to attach the second one. One sheet needs 4-5 nails. This amount is quite enough, since after the tile has warmed up under the sun's rays, it will be glued to the base of the roof and the sheets are securely glued together.

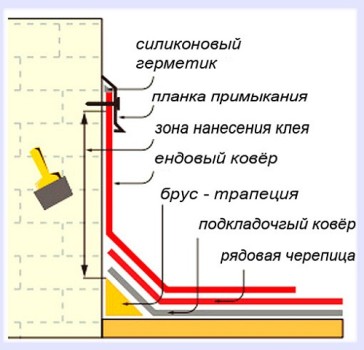

During laying, the bituminous tile has to be fastened to different elements of the roof. For example, it can be a furnace or vent pipe, a parapet, etc. In a place where the tile adjoins, say, to a pipe, it will inevitably result in a slit through which moisture will fall under the roof. Therefore, in the places where the roof is adjoined, the roof tile is fastened as follows. First, a triangular bar is attached to a vertically projecting object (say, this is a chimney). After the tile is set on the bar, while running a little on the pipe. On top of the carpet, which is used for the installation of the valley cover. The carpet should cover the surface of the pipe 30 centimeters from the roof surface. Then the lower part of the pipe is closed with a special metal apron.

To prevent the snow from accumulating during the winter, a special pyramid is installed there, which has two faces, close to the pipe, the so-called razlochka. Thanks to this simple construction rain water and snow will slip on the walls of the pyramid, not accumulating behind the chimney.

Very often through the roof you have to remove the pipes of any communications. In this case, special elements are used for the bitumen roof. They are elementarily fastened to the roof surface with the help of nails and reliably protect the roof from leaks.

As for the installation of tiles on the roof ridge, this is perhaps the simplest part of the work. For this purpose, a special tile is sold, which is called "skate". Each detail has a perforation that divides it into three parts. Fits skate tile with overlapping of about 5 cm. It is fastened in several places by nails.

Bitumen shingles prices, manufacturers

The undisputed leader in sales on the territory of Russia is Shinglas shingles shingles. Her production is engaged in a factory for the production of soft roofing materials "TechnoNIKOL). At the moment, this is the only brand of bituminous shingles in Russia, which has a marking of compliance with European standards. In the production of bituminous roof shinglas take into account the harsh climate of Russia.

Depending on the series and the brand of shingles, the manufacturer provides for its products a guarantee of 10 to 60 years. Accordingly, the price varies from 200 rubles per sq. M. meter.

The carpet on the valley will cost an average of 3400 rubles per packing, and the packaging of ridge tiles - 2000 rubles.