Sprayed polyurethane foam is a relatively new technology in the insulation of residential buildings. How comfortable it will be to live in a new house depends on a combination of many factors and nuances of the construction process. Of great importance is the quality of insulation, which is used in the construction of a new building. Today, the market has a lot of thermal insulation materials of different levels of quality, price, composition and technical characteristics. If you want to get a 100% result, it's worth paying attention to the newest heat-insulating materials, in particular, to polyurethane foam.

Content

Field of application of polyurethane foam

Professional builders have recognized this type of insulation as one of the most effective. In developed European countries, polyurethane foam is used universally. Domestic builders are not yet actively using this heat insulator for one simple reason: most workers do not have the necessary skills and experience with specific equipment. For the developer, polyurethane foam is interesting, primarily because of the long enough service life, which can reach several decades. In addition, it is a universal material - it can be used for warming both residential and industrial buildings, various storage facilities, warehouses, for the warming of cellars, roofing, various communications.

Polyurethane foam is perfectly applied to the most diverse surfaces: concrete, reinforced concrete, aluminum, steel, cement plaster, wood, etc. The material is suitable for both internal and external works, insulation of floors between floors, cellars, internal and external walls, facades, socles of buildings, floor and roof. Polystyrene foam, if you can say so, self-sufficient insulation, when working with it, no additional materials are needed - glue, fastening elements, etc.

Advantages and disadvantages of polyurethane foam

- Ecological compatibility. This heater can be safely applied outside and inside the residential building, it does not hurt the health of people. In addition, polyurethane foam has excellent sound insulation characteristics.

- Polyurethane foam plays a very important role in providing comfort inside the building: humidity will always be optimal, in summer the house will be cool, and in winter it will be warm.

- Polyurethane foam is applied with a continuous layer without seams, so the so-called "cold bridges" are excluded.

- The material is not inclined to ignite, but if there is an open fire nearby, then under its influence the material will still burn and emit toxic fumes. To avoid fire, the applied material is covered with a layer of special paint. Since polyurethane foam has excellent adhesion, it is able to cling tightly to virtually any surface, while filling the smallest cracks.

- All components of the thermal insulator have a water base. In the polyurethane foam add substances that repel rodents. In addition, these additives have anti-corrosion properties.

However, like most building materials, polyurethane foam has some disadvantages

Among the main ones, it is possible to allocate a sufficiently high cost. Polyurethane foam, whose technical characteristics significantly exceed the majority of common heat insulators, is quite expensive. In the process of spraying the material, it is necessary to protect the eyes and respiratory tract, since the constituent of the material - isocyanite, can cause severe irritation of the mucous membranes. If the surface on which the thermal insulator is applied has a weak structure, the expanding foam can damage it.

Preparation for the deposition of the material

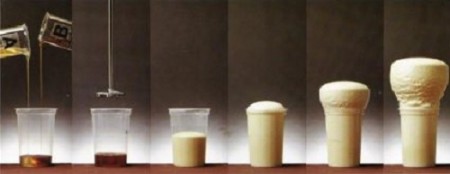

To obtain the finished foam, it is necessary to mix isocyanite and polyol in equal proportions, after which the mixture is applied to the surface with a special gun. One of the components of polyurethane foam is a polyol, it is a mixture of foams, polyester, fire supplements and foam control substances.

Before mixing the components, they are pre-shaken with a stirring device.

Before use, the finished material is passed through a fine metal mesh. In the process of working with these materials, it is necessary to protect them from contact with moist air and from interaction with foreign substances. Storage containers should be carefully closed. The work process must be planned in such a way that the finished foam is fully used as quickly as possible. If contamination of the material has been allowed, it must be carefully filtered.

Equipment for polyurethane foam sprayed

Since work with polyurethane foam is carried out in large volumes, it becomes necessary to use special equipment - the material is applied with low pressure devices of domestic and foreign production. In this case, you need to use personal protective equipment: wear overalls, goggles, rubber gloves, boots and a respirator.

polyurethane foam, workflow technology

Warming of the sprayed polyurethane foam is carried out in dry and warm weather, or in a warm room. At atmospheric precipitation, sputtering is not carried out, since the material is applied only to a dry and clean surface and full hardening of the previously deposited layer. If the ambient temperature is below the recommended one, then the process of work is divided into several stages: first the first, thin layer is applied. After it completely hardens, a second layer of the required thickness is applied from above.

Work always begins with the most difficult places. This can be chimneys, ventilation holes. At the same time the polyurethane foam layer should not exceed 1.5 centimeters. To achieve the desired result, three layers of insulator are applied. To process one surface, only one day is allocated. If the workflow for some reason drags on for several days, then each time before the beginning of the spraying the surface is newly prepared. In order to prevent contamination of nearby surfaces, they must be covered with matter.

You can produce heat insulation works as in the process of building a new building, and in the process of repairing a house that is already in operation.

Can I work with polyurethane foam myself

In principle, almost any construction work can be done with their own hands. That only requires some knowledge of the process, its nuances and tricks, as well as practical experience.

Before starting work, the surface must be gently cleaned, it must be dry. The optimum temperature of the treated surface is from 12 to 15 degrees Celsius. Any protruding elements larger than 5 millimeters must be removed.

To work, you need a device for spraying foam: cylinders with components of a heat insulator, a pump and a sprayer with a nozzle. After the foam hit the surface, it very quickly freezes, so apply a layer of foam evenly. During operation, it is necessary to constantly monitor the pressure in the cylinders and hoses, the temperature of the mixture, and other parameters. Monitoring is carried out using sensors installed on the equipment.

The working mixture should have a temperature of no more than 30 degrees. Otherwise, the process of foam formation will proceed slowly, and the consumption of polyurethane foam will be significantly increased. The thickness of the applied layer will have to be counted on the eye, which requires some skill and experience. If you work with polyurethane foam for the first time, it is better not to immediately apply a layer of the required thickness. Make a small even layer, then you can apply a second one.

If you take into account a lot of difficulties that arise during the work, you can definitely recommend contacting specialists. Warming with polyurethane foam is not a cheap pleasure, but the result is definitely worth the money. And the more the insulated area, the lower the cost of warming the square meter of the surface. At the same time, all the work is done by professionals who guarantee quality.

Sprayed polyurethane foam, the price for one layer: from 500 to 900 rubles. The cost depends to a large extent on the density of the applied material and the place where the work is carried out.

most popular brands of polyurethane foam

Exothermix 300. Has more than 90% of the closed cells. It is used for outdoor insulation.

Exothermix 600. Open cells, designed for internal insulation.

Healtok Soy is a versatile material.

Sealection - for internal works.

Sprayable polyurethane foam. Reviews

The effectiveness of this heat insulator has been repeatedly confirmed by numerous reviews, including at construction forums. All the owners of houses, in the process of thermal insulation of which polyurethane foam was used, were satisfied and share exclusively positive impressions of this modern and extremely effective thermal insulation material.