By purchasing a battery tool from the manufacturer, you will be puzzled by the high cost of the screwdriver battery pack. The principle of the battery instrument is based on the physics of the electrolytic process. Restore and repair the battery pack will be available to those who are friends with electrochemistry and circuitry.

Content

Why is the battery running down?

The most demanded electric tool for assembly work is a screwdriver. There are electric screwdrivers (drills) running from a mains power source and battery.

The cordless tool is simple to carry out the work, however it requires the recovery of the screwdriver battery. Recall that an important parameter of the battery tool is a capacity that provides information about the time value of the output current. The accumulator capacity of a screwdriver depends on the battery voltage.

For example, with a battery voltage of 12V, with a capacity of 2 A / h, the power of the instrument will be 24 W. Regardless of the type of screwdriver batteries, the loss of charge capacity is an inevitable physical process. Let's say that the capacitive loss is related to the intensity of the instrument's use and the oxidative processes inside the battery (sulphation).

If you intend to perform the repair of the battery with your own hands, you need to understand the possibilities of the screwdriver battery circuit for a separate type of elements.

The device of the battery pack - cans and their contents

The screwdriver rechargeable unit consists of a set of cans, having a cylindrical shape and a standard size. Different banks of the battery screwdriver capacity, the marking of which is indicated on the element and is measured in Ampere / Hours.

Thus, the total voltage on the battery contacts is the sum of each element.

types of battery cells

Any screwdriver battery pack is equipped with one of the following:

• nickel-cadmium batteries (Ni-Cd) the voltage rating on the banks is 1.2 V, the average number of charging cycles is 600

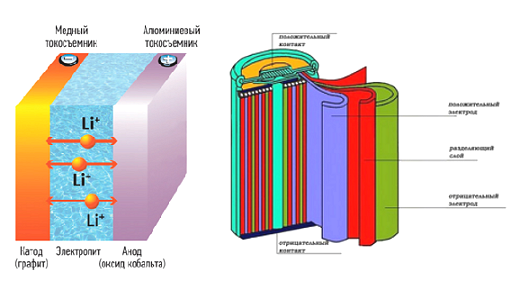

• lithium-ion (Li-Ion), with high characteristics: 180 Wh / kg and 250-400 Wh / l, and operating voltage 3,6V

• nickel-metal hydride (Ni-MH), the voltage is 1.2V.

Nickel-cadmium batteries have an energy capacity from 1200 to 1500 mA / h. The total power is provided and maintained by the number of cans inside. For example, 12 V will require 10 pieces, for 14 V - 12 pieces.

It is proved that the main reason for the loss of capacity in batteries from nickel-cadmium is the boiling-off of the electrolyte. In practice, it has been established that nickel cadmium batteries for screwdrivers are the most tenacious and are subject to repair.

For comparison with nickel-cadmium and nickel-metal hydride elements, the loss of capacitance in lithium-ionic cells is much smaller, but the service life of charging cycles is from 500 to 1000 cycles.

The recovery option for a li ion battery for a screwdriver is the most laborious, however, it offers the maximum advantages: an increase in the number of fast charge cycles and the absence of a "memory effect".

Ways to restore capacity

There are several practical ways to restore capacitive charge:

• the method of compaction of potential

• Firmware with voltage and current exceeding the nominal values

• replacement of detected defective items.

Method of compaction of potential It is effective in case of presence of electrolyte in a can, but with loss of initial volume.

It does not hurt to remember that with a critical volume of electrolyte firmwarecadmium batteries for screwdrivers are powerless. Therefore, elementary resuscitation is required - injection of electrolyte into the can using a needle of a medical syringe.

restore nickel-cadmium batteries

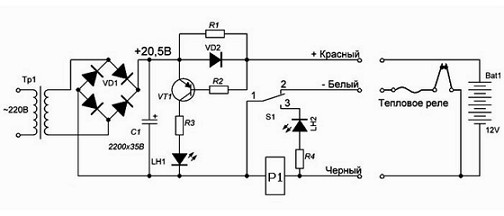

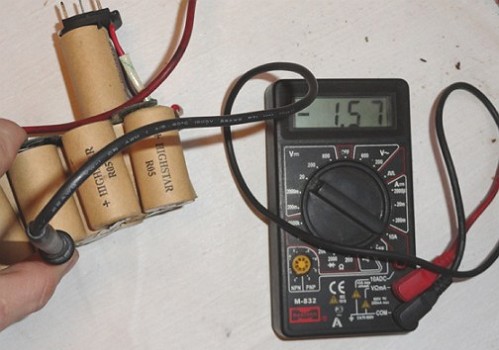

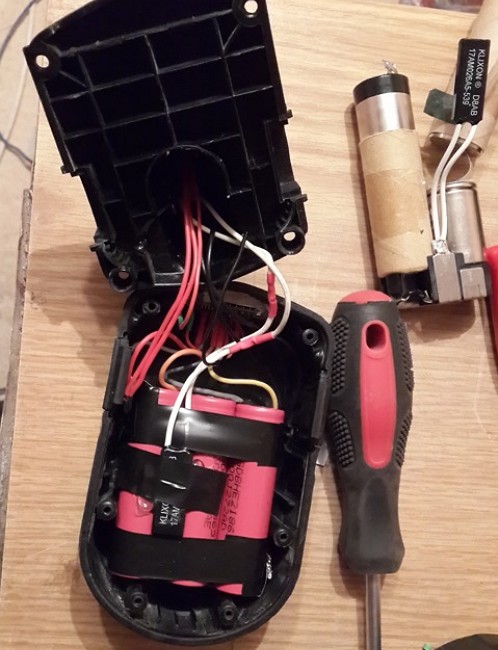

For nickel-cadmium batteries, the internal structure of which is made by a single technology, the most accessible is the method of replacing faulty elements that are found by measuring the voltage on the battery plates. The body of the battery pack is disassembled and the batteries are removed.

The algorithm for the recovery process of a screwdriver battery consists of the steps: "assembling a pack of cans" - "soldering nickel strips" - "charging the battery until the working voltage is reached."

Initially, what this algorithm assumes is to check the batteries for compliance with the declared performance (voltage). Therefore, it is necessary to touch the battery to identify the faulty components and replace them.

How to sort through the battery is shown in the video.

After identifying the faulty battery cells, we solder and replace the new elements with tinned contacts and weld the plates to the battery. Alignment of the potential on the collected battery is carried out using the charger included in the delivery of the screwdriver and set the banks to be charged.

Recall that the voltage range for existing battery models is different and is within 6-22 V and assumes a battery charging time of 6-8 hours.

More detailed information on how to restore the battery pack is available here.

If the power of the voltage for the tool is still not enough, then the reworking of the screwdriver battery on the Li-Ion is necessary.

conversion of the unit to lithium-ion batteries

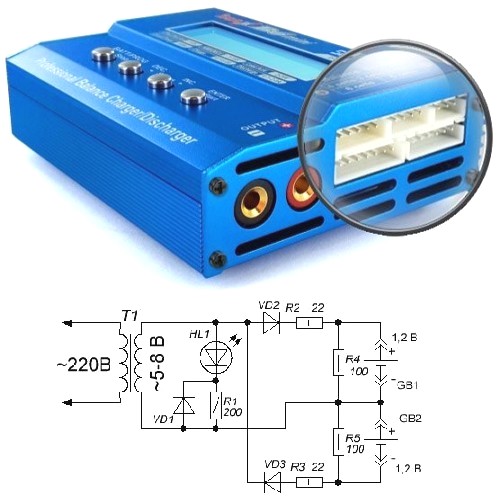

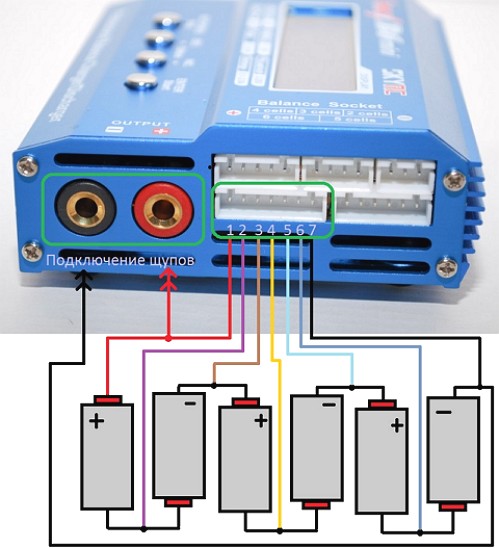

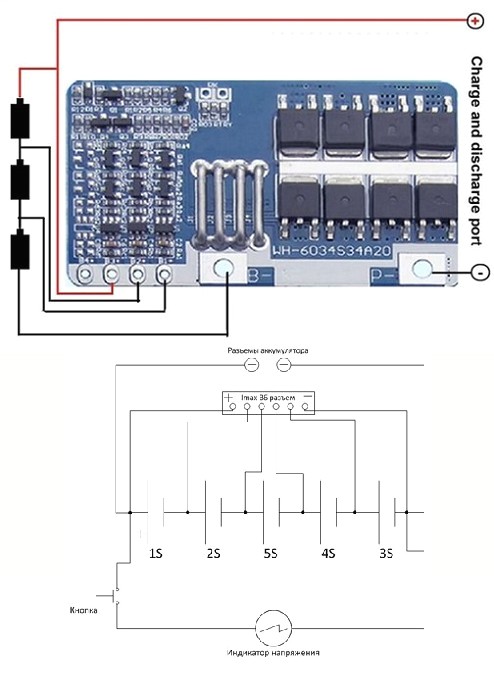

Remaking the battery will require the connection of the balanced connector of the IMAX B6 controller according to the 5s-2p scheme (5 consecutive two in parallel) or 5s-1p. Algorithm for remaking is similar to the algorithm for restoring cadmium-nickel batteries.

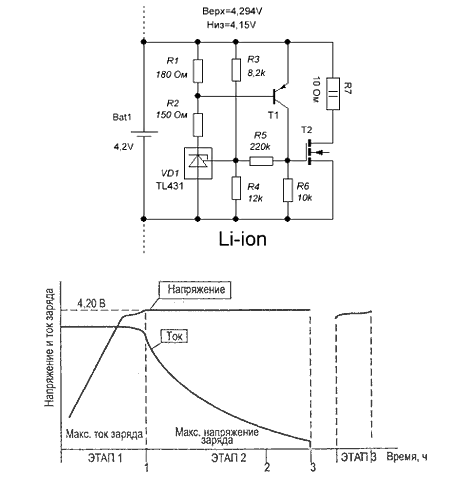

Let's say that li ion rechargeable batteries are charged in combination in two modes: initially up to a voltage of 4.2 V at constant current and at a constant voltage up to the declared nominal value.

How to implement a rework on lithium-ion batteries, suggested in the video.