The modern floor made of laminate is very popular among those who appreciate comfort, convenience, beauty and economy. It is chosen not only for a relatively low price, but also for exceptional external qualities, as well as for advanced technical characteristics. The floor of laminate is often used as an alternative to natural wooden parquet floors. Many believe that the laminate floor looks even richer and more beautiful.

Content

Laying the laminate on the concrete floor

To produce a floor covering, and the modern floor of laminate flooring, including, you must first align this floor. Although this process is quite time consuming, but you can do it on your own.

To do this, first carefully remove the old floor covering and carefully clean the entire surface of the floor from dust and contaminants.

Then we take the building laser level and place it on the highest point of our floor in the room where we are going to lay the laminate.

Now the laser level must be turned on.

So, we saw that perimeter, by which we will carry out the alignment of the floor.

Then draw the chalk marks on the red laser line.

On these marks we extend a cross-like rope.

Why do we do all this? But for what.

If all our rope construction does not touch the floor, then everything is fine and you can proceed to the next step.

And if you touch, you can try again to design the perimeter on a new one, using the same laser level.

And you can just try to lift our marks and ropes by one to two centimeters.

Upon reaching the expected positive result, we arrange the so-called beacons, which help in the orientation for correct alignment of the floor.

It is very convenient to use for this purpose special guides, made of plasterboard, laid along at a distance of just over half a meter from each other.

These guides are fixed with long self-tapping screws using a perforator.

Now we begin work on the floor screed for the subsequent laying of the laminate.

To do this, we use a building mix consisting of a solution of sand and cement, pouring it between the guides a uniform layer.

At the end of the whole work, we carefully level the mortar, spreading the mixture on the floor to the level of previously installed beacons.

Now we are waiting for the final drying of the mixture (this can be spent from several days to several weeks, depending on the fill layer) and proceed to laying the laminate on the floor with our own hands.

Before you start laying the laminate on the concrete floor, it is first put on the substrate in the number of two pieces - soundproof (softening) and vapor barrier (conventional polyethylene film), which is laid on the previously prepared concrete floor so that nowhere there is no gap, preferably in a large overlap (20 cm) and fasten with a special construction tape.

Soundproof (and having a softening function), the substrate is immediately placed on top of the vapor barrier (polyethylene).

This is necessary in order that the laminate will not constantly hit the concrete floor during use (walking on it) and would last much longer.

There are such types of softening substrate under the laminate, as polymeric or cork.

Both species are equally good.

The sound-insulating substrate is laid exclusively by the joint in the joint, also fastened with special construction tape.

Laying a laminate on a wooden floor

Before laying the laminate floor, the wooden floor must be leveled, and it is desirable to completely re-overhaul. This is necessary to make the laminate last long.

So, to begin with, we will start parsing the old wooden floor and start laying the new one.

But if you completely replace the wooden floor is not possible for you (still, it's expensive), then we can advise you to stretch the old floor with screws.

This will have to be done in order, first of all, to eliminate its creaking, and also to extend the lifetime of the laminate.

After we stretched the floor with screws, we need to lay a sheet plywood, 5-10 mm thick, so that between the seams there would be a free space of 2-3 mm.

Between the laminate and the wall also leave a gap of 8-10 mm (closing it with a skirting board), since the laminate subsequently has a thermal expansion approximately equal to the size of the gap.

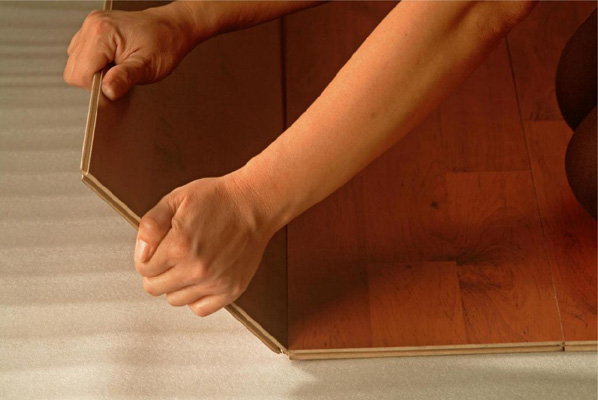

Laying the laminate on the floor

For modern warm floors a special laminate is developed, its cost is higher than that of the usual one.

But the warm floor must meet certain requirements for its subsequent finishing with a laminate.

For example, it must be equipped with a floor heating control to keep its temperature under control and prevent its sudden jumps.

The humidity in the room where the laminate is laid must also be at a certain level, otherwise the floor may be shattered, and the seams may disperse.

Before you begin laying the laminate, the warm floor must be prepared.

To do this, it is switched on for a couple of days for heating, and then it is also switched off for a couple of days.

Further laying the laminate on the warm floor is no different from any other standard installation.

To strengthen joints on a laminate it is additionally necessary only in those areas of a premise where carpeting covers or furniture is established.

That is, where there is no free circulation of air and the laminate will be heated much more than in other places, from which the joints that are located there, may in time dissociate from the temperature rise.

After the laminate is laid, for a couple of days you need to set a certain floor temperature and do not change it all this time.

In the future, too, do not admit its sharp differences, not allowing neither excessive heating nor hypothermia.

If you still need such a measure, you should try to do it as smoothly as possible.

The main advantage of a laminate with respect to its laying on a warm floor is that it is the most acceptable for this coating.

To ensure free access to heating systems, there is no equal, since the floor of the laminate is very easy to disassemble and re-assemble, replacing, if necessary, the areas requiring removal.

In general, the laminate is quite durable and if the floor is mounted correctly and operated by all the rules, the repair will not be required for a long time.