Greenhouses with geothermal heating - the original method of using energy from renewable sources and elementary laws of physics. The scope of this alternative energy type is quite extensive, but more often it is used for heating livestock farms, poultry farms and greenhouses. The use of natural heat sources makes it possible to obtain substantial savings, and consequently, to reduce the cost of agricultural products. Calculations of the geothermal heating system for each object are made individually.

Content

Geothermal heating and its advantages

The purpose of the heating system of the greenhouse is to ensure temperatures sufficient for growing crops and ripening their fruits. To maintain the necessary temperature inside the greenhouse, the greenhouse effect alone will not be enough in winter, but the use of traditional heating systems leads to a significant increase in the cost of production. Contrary to the popular belief that new ways of alternative energy saving are something akin to a perpetual motion machine, geothermal heating systems really work for savings and have a number of undeniable advantages:

- working completely autonomously, they do not require the supply of energy carriers and are completely independent of the change in their value,

- operation of geothermal systems is a little expensive procedure,

- systems do not require expensive maintenance, reconciliations, periodic repairs,

- provided that the service life of the geothermal heating system is at least 50 years,

- the system allows to provide the necessary temperature inside the greenhouse throughout the year,

- with a balanced soft climate in the heated space, the system generates uniform ventilation and regulates the humidity level.

Geothermal heating - the principle of operation

The functioning of geothermal heating systems is possible due to the stable temperature of the soil at certain depths. In winter, it can be 5-7 degrees C, in the summer - 10-12. Such indicators are enough to ensure the basic temperature in the greenhouses, due to the radiation of the sun and the presence of the greenhouse effect in winter, the air temperature in the greenhouse increases several times.

In the summer heat, the system works to normalize the microclimate by lowering the temperature to 23-27 degrees. In principle, this temperature is optimal for growing almost all types of vegetable crops. Thanks to air exchange throughout the day the soil accumulates heat, at night - it gives it and heats the greenhouse, which helps to equalize the daytime and night temperatures.

Geothermal greenhouses are effective even in the conditions of the north, of course, in severe cold climates additional heating will be required, but the costs for it will be quite acceptable.

Of course, the construction of a greenhouse with geothermal heating is not an easy task, the first problem is the extraction of a huge volume of soil - after all, the installation of underground communications will be required at great depths. Nevertheless, the cost of building materials will be significantly lower than the anticipated costs of gas or electricity used in traditional greenhouses, and the efficient operation of the geothermal system quickly compensates for all financial costs.

Construction of the heating system

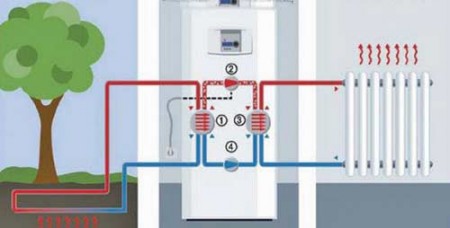

At its core, the construction of a geothermal heating system is quite simple. It represents two contours, located under a layer of soil and on a surface. With the help of the first, heat energy is collected, i.e. it is a heat exchanger. Its installation is carried out either in non-freezing reservoirs at the appropriate depth or in the ground, below the freezing point.

Pipes of the second circuit are poured with water or water with the addition of an appropriate amount of antifreeze. The energy absorbed by the coolant flows to the heat pump equipped with two heat exchangers, geothermal heating works from the energy received in this way.

There is also an option when geothermal heating drills a borehole about 100 m deep, this option is much more efficient, but drilling at such a depth is very expensive.

Planning

First, it should be noted that it is impossible to equip an operating greenhouse with effective geothermal convection. This is difficult to perform on the technical side, but even in the case of modernization, the efficiency obtained from it will be significantly lower than that which can be obtained if the design work for the construction of a new facility is properly carried out.

Secondly, to obtain an economic effect, it is necessary to design geothermal systems in year-round working greenhouses, and their minimum area should not be less than 50 square meters. m, an increase in area will help increase efficiency. The site for the construction of the facility and its dimensions should be determined even before the start of the design work.

It is of no small importance to determine the location for construction, the size of the site should significantly exceed the area of the future greenhouse. On a site there should not be different constructions or trees grow. When planning a greenhouse with a length and width exceeding 14 m, the dimensions of the sides of the excavation should be increased by 3.5 m. With a length of less than 14 m, a pit will be required, the sides of which will exceed the sides of the structure by about one third.

You can dig a foundation pit yourself, but you can use the technique in the process. From the materials should be prepared:

- clean river sand,

- fine crushed stone,

- rubble brick,

- polystyrene plates,

- 110 mm pipes and nodal connections to them.

To name the exact amount of costs is difficult, roughly geothermal heating has a cost of about 120 - 140 dollars for each square. m of the finished heated structure. The density of laying underground utilities will be inversely proportional to the average temperature of a specific climatic zone.

Installation of geothermal heating

The main characteristic of a functioning heating system is the amount of calories of thermal energy that it generates. Since there is no regulatory framework for geothermal heating systems, it is recommended to use the SniP provisions for the design and installation of general-purpose climate systems in detailed calculations.

Effective operation of the system can provide air ducts, the density of accommodation will be no less than 2.7 m per 1 sq. Km. m, in a cold climate, underground communications are placed more densely.

Where to start installation of equipment for geothermal heating

The work will take from 2 to 4 weeks. The most laborious stage will be excavation of the soil, the best option is to hire a special technique, namely, an excavator. The installation of communications is of no particular difficulty, it can be handled on its own.

Depending on the climate and the depth of soil freezing, the depth of the excavation is calculated, for the regions of the middle belt there will be sufficient depth of 3 to 3.5 m. If the climate is warmer, the pit can be made smaller. The upper fertile layer of the earth is neatly removed and preserved, the clay layers are removed. The shape of the excavation can be rectangular or trapezoidal, its walls are not required to be fastened.

At a depth greater than 0.7 m, the excavation slopes should be insulated with expanded polystyrene plates. The bottom of the pit is covered with crushed stone (15 cm), then - a layer of sand, about 30 cm thick, is compacted. Then, the inner contour of each of the walls of the future structure is beaten with a cord and its longitudinal axis is determined.

For laying air ducts use PVC sanitary pipes with a diameter of 110 mm. The pipes are laid in accordance with the marked contour of the passage. It is recommended to lay pipes "snake", in this case the pipeline is divided into sections with a width of 1.5 - 2 m. The distance of the pipeline from the pit walls should be from 0.3 to 0.5 m. Each of the ducts should have a tee connection in the center with three sockets. At the next stage, the central branch is withdrawn from this connection upward, focusing on the longitudinal axis of the greenhouse.

After the construction of the greenhouse, the central branch of the duct is increased, with the ends of the pipes to be below the roof level by 30-35 cm. The lateral branches of the segments are also withdrawn, the distance between them and the walls of the greenhouse must be at least 0.2 m. The central and lateral branches with the help of plastic plugs or membranes made of polyethylene. Vertical sections of the system are fixed by filling their base. The branches facing the surface must be strictly vertical.

After completing the installation of the system, the pit is dropped to the level where the upper limit of the heat-insulating slabs is 70 cm from the ground level. The pit area, which is outside the inner part of the greenhouse, is covered with a layer of foam and covered with a layer of soil until it rises to the soil level.

The walls of the formed pit are fixed by means of a panel formwork, then they are insulated with expanded polystyrene plates. The deepening formed inside the greenhouse is covered with chernozem, not reaching the ground level by about 35-40 cm.

principle of the air exchange process

Normally, the functioning of the system does not in principle require the organization of forced air exchange. To avoid sudden temperature changes and improve operating parameters, it is possible to install a self-made exhaust fan and a filter device. If a forced air exchange system is installed, it will also filter the air. You can make the system yourself using a fairly simple scheme.

mosquito net installation

To protect the system from getting into it various insects install a mosquito net, the size of the cells can be from 02 to 0.4 mm, the net is stretched on the embroidery frame and pasted into the case in which the fan is placed.

how to deal with condensation

Since the temperature indices of soil and air can differ significantly, it can be assumed that condensate will form in the pipeline. To prevent this phenomenon, holes are drilled in the pipes with a diameter of 5 mm, up to 15 pcs per running meter. When laying pipes, place the holes down. To adjust the humidity of the air, 3-5 liters of water can be poured into the segments.

If heating is carried out by the principle of air convection, then care for it will consist only in cleaning mosquito nets. Heated greenhouses - this is an advantageous option for obtaining optimal temperature indicators by using an autonomous climate equipment.