Carpentry and carpentry tools in the arsenal of a house master are also necessary, like a hammer, pliers or a screwdriver. But in addition to the availability of this tool, it is advisable to use the chisel or chisel skillfully. It's right to say: "How to sharpen the instrument, and will play."

Content

What is a chisel and what is a chisel

The chisel on a tree represents the carpenter's tool intended for hollowing out deep grooves and nests.

The tool has the form of an elongated bar made of metal, fixed in the handle. The end of the handle of the chisel is looped with a crimping element, which protects the handle from splitting.

The chisel is a hand-worked woodworking tool in the form of a sharpened steel plate with a handle. The chisel on wood is intended for cutting facets, sampling small depressions and processing small curved surfaces and grooves. Structurally the chisel consists of a sharpened blade and handle in most cases wooden, less often metal.

The chisel differs from the chisel by the angle of sharpening of the cutting element, as well as by the absence of a double-sided chamfer along the entire length of the blade, with respect to the side of the grinding. Another difference between the carving chisel and the chisel is the larger diameter of the metal rod, so it is impossible to confuse the chisel with the chisel.

Classification of chisels

Chisels are classified by the way of advancement in the cavity of the material, the shape of the handle and the size. However, the main parameter of the classification is the form of the instrument: longitudinal or transverse. Therefore, the further use of the chisel depends on this form.

The way of promotion and the principle of the chisel

The method of moving the chisel in the material can be carried out at the expense of short-term impacts on the handle with a special tool: a hammer or a mallet. This type of chisel is used when working with hard wood species, which requires considerable physical effort.

Outwardly chisels of this type have a long handle and a cutting part. When working, the chisel is held with one hand, and the second produces a rhythmic blow to the handle. To strengthen the design of the handle, amplification is made-a loopback. At work it is better to give preference to polyurethane or rubber hammer. Another type of chisel has a long handle, but a shorter cutting piece. This chisel is designed to work with both hands and advance the tool.

To work with this type of chisel is better with soft wood species. The handle head has a round and smooth shape, comfortably placed in the hand. You can use a rubber hammer in the case of dense wood for better advancement in the material. There are also chisels, the advancement of which in the material is carried out exclusively by hand.

Chisels of this type are much thinner and shorter than other types. The progress in the material will depend on the angle of sharpening of the cutting part and the size of the object being processed. With this kind of chisel, professional woodcarvers and inlayers of wood products prefer to work.

Cutting element shape

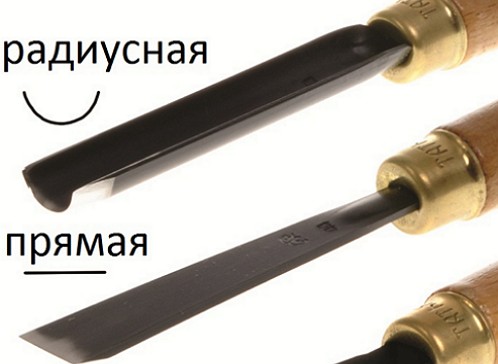

The transverse shape of the cutting element, and this means the end profile of the blade is divided into the following types:

Transverse shape

• direct

• flat

• Radius

• cramped

• Angular

Chisels with a straight blade have a strict shape without bends.

Chisels having a flat transverse profile are distinguished by the thickness and width of the web, as well as by the straight or curved shape of the cut.

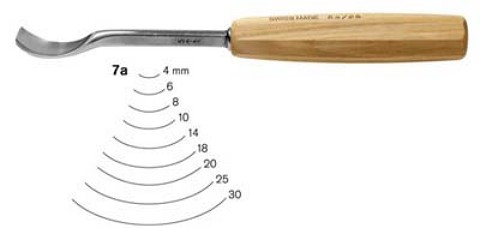

Radius chisels are the most common type. Radius chisel is a cutting tool, in the profile of which there is a part of the circle.

When choosing a radial chisel, you can make a simple test: the chisel placed on the end should ideally outline a circle around itself. Agree that such a universal chisel will allow you to make carpentry quickly and accurately.

Clapper or box chisels are tools in which the cutting part is equipped with bumps of various heights.

Chisels have angular profiles in the form of a Latin letter V. The main parameter of incisors of this type are the height of the side of the angle and the magnitude of the angle reaching 90 degrees.

Longitudinal form

• Cranberry

• curved.

Chamomile chisels have a steep longitudinal bending of the cut, starting to bend closer to the end of the chisel blade.

Chisels curved are holders of full longitudinal bending of the blade. In this case, the canvas has a bend not in a separate part, as for example in a crickace, but completely all the canvas.

Work with the chisel and chisel will be comfortable if the tool is well and properly sharpened. How correctly to sharpen the chisel?

How to sharpen a chisel

Any home master knows that the working state of the hand cutting tool is characterized by a good grinding. It is not difficult to guess the quality of the chisel sharpening by considering the cutting edge of the tool. The appearance of cracks and warped areas on the blade already indicates that it is time to look for a bar, emery or abrasive circle for sharpening.

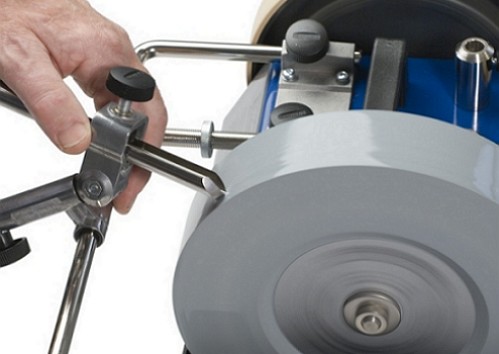

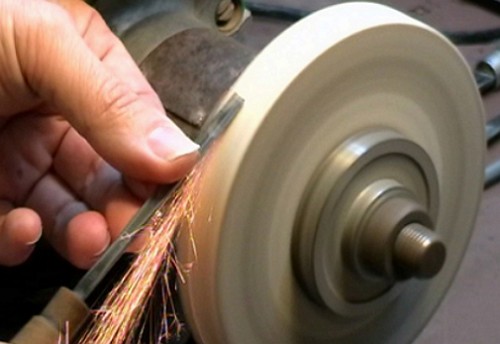

Grinding work is performed using bars, as well as abrasive grinders of industrial production. To produce grinders, carborundums, fine-grained sandstones and known abrasives are used.

Before starting the grinding work, the bar must be moistened with engine oil. The cutting of the chisel blade on the bar is performed by applying the entire plane of the pointed part.

Pressing the blade of the instrument with the hands to the bar, progressive movements are made along the movement of the chisel. The grinding work on an emery or abrasive wheel is similar, only in this case the motion is produced by the circle itself. If, after sharpening the chisel blade, burrs are formed, bending in the opposite direction, in this case the chisel is turned over and pressed against the abrasive tool with the whole plane. These techniques are repeated until burrs are eliminated.

Final finishing of the blade is made with polishing paste. For sharpening of semicircular, curved or angled chisels, the principle and methods of sharpening are identical. When sharpening the tool, you must carefully monitor the current state of the work surface, avoiding distortions and fillets. Therefore, the state of the abrasive or emery wheel play a significant role in the grinding process.

How to sharpen the chisel with your own hands will help you with the video.