What is attractive for a quality soundproof room? Of course, this is the comfort of staying in a world of silence. If you dream of making the best noise insulation of the floor with your own hands, then it is necessary to work on strict technology to avoid mistakes and get an excellent result.

Content

One of the components of soundproofing is noise insulation of the floor. Correctly produced noise insulation of the floor allows you to avoid the presence of shock noise, which are transmitted by walls, floors and ceilings in the apartments. What methods and methods can be isolated from the ubiquitous noise?

Modern soundproof materials

The nature of sound waves assumes their propagation not only in the air environment, but also through the transmission of waves and sufficiently dense materials from which the houses are built.

Sound insulation of the floor with the use of decorative coatings - linoleum on a solid basis, carpets and carpets, as well as foamed polyurethane can not fully produce noise insulation and sound absorption of sound waves. Therefore, the most effective way to noise insulation floor in the apartment can be considered the use of modern insulating materials.

Among the numerous noise insulation materials you can confidently call the following:

• Acoustic mineral wool

• Roll-up sound-proof materials

• Soundproof membranes

• sound absorbing substrates

• granulated mixtures.

Acoustic mineral wool is a hydrophobic plate, having the basis of basalt mineral wool. The most common materials are: AcousticWool ™ Floor, AcousticWool ™ Glass Floor. The material is designed to enhance the soundproofing properties of floating floors.

Rolled soundproof materials are a fiberglass with applied polymer-bitumen coating, which allows to produce a screed directly on the material, providing a good acoustic insulation.

Floor Soundproofing Technology

The technology of noise insulation works in the apartment with their own hands consists of several stages and depends on the selected noise insulation material: plates, membranes or granulating mixtures. For each insulating material, its own technology of work is provided.

Try to avoid a number of mistakes when carrying out insulation work with:

• increase in the surface weight of the screed

• Increase the total thickness of the insulation layer, using materials with a low value of the modulus of elasticity

• Separating the screed from the surface of the walls with damping gaskets.

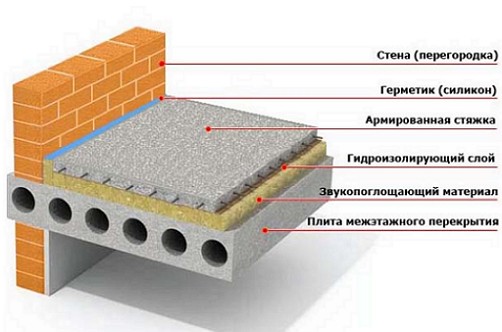

The initial stage is the preparation of the working base of the overlap. At this stage, the existing cracks and potholes are embedded on the surface of the base and the bumps or irregularities are removed. It is preferable to produce a vibroacoustic sealant.

The next step is the closing of the insulating material using a special film or reinforcing mesh. The subsequent stage of the screed is the most important, because the reinforcing layer will serve as a kind of bundle of subsequent layers. Laying waterproofing material must be done with the processing of joints. Strips of noise-insulating material are installed along the walls to the height of the level of the future screed. Such an important point to exclude unwanted sound penetration.

For filling the screed, it is better to give prefabricated dry construction mixture with good adhesion and elasticity. The production of a quality screed will avoid violations and errors in the process of noise insulation. The final stage can be considered the finish of the floor. When laying the floor covering, it is necessary to provide a technological gap between the finish coat and the wall of the room. The technological gap is closed with the help of vibration isolation sealant and decorated with plinth.

Noise insulation of the floor with the use of modern soundproof materials does not cause any difficulties for installation, because the technology is simple and accessible. In addition, when carrying out installation work using known materials, errors in laying are practically eliminated.

Soundproof Plates

Sound insulation boards are a sheet material with mineral filler. Mineral filler is able to delay the sound wave in the frequency range perceived by the hearing organ.

Reducing the level of impact noise from the use of soundproofing plates reaches 75 percent, and the level of air noise to 85 percent. The installation of soundproofing plates is available for the production of works independently.

How to make noise insulation of the floor with the use of soundproofing slabs is shown in this video.

Soundproof membranes

The technology of laying soundproof membranes and substrates with noise insulation of the floor from the neighbors from below suggests some nuances. When covering the liners of insulators and membranes, it is necessary to observe the continuity of the coating of the working surface.

In practice, this means that omissions and uncoated areas can negate all efforts for noise insulation of the floor in the apartment. In addition, special attention should be given to the layout of the buffer or damper tape for soundproofing work.

The main purpose of the damper tape is to separate the screed from the walls, because when the temperature and humidity changes in the air change in the room, the floor screed will expand.

Sound insulation of the floor with the use of an acoustic soundproof membrane TECSOUND is presented here.

Granulated mixture of elastic material

Sound insulation of the floor with the use of a granulated mixture of elastic insulating material is of great interest for the owners of country houses. The granulated mixture is designed and used for the installation of "floating" floors on floor surfaces with a large floor area.

The technology of coating with expanded polystyrene granulate with a compensating rubber additive is quite simple and can be done by one's own hands.

The mixture is applied to the working surface with a layer of up to 30 mm thick and allows achieving excellent sound insulation characteristics. The final polymerization occurs in 24 hours. How to produce noise insulation using a granular mixture of elastic material is shown in this video.