Within the framework of this publication we will consider a rather interesting modern finishing material. It's about torn stone: what is it, where it is used, what kinds of this material are there, how to work with a torn stone, etc.

Content

What is a ragged stone

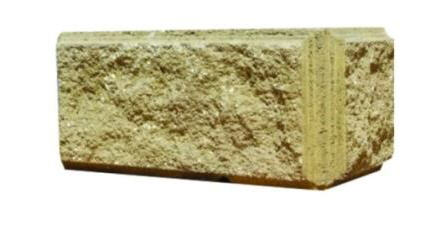

Ragged, or, as it is also called, a wild or rough stone is a material intended for internal and external finishing of country houses, cottages, fences, etc. The front side of the material imitates a natural, "wild" rough stone with an uneven rough texture. The reverse side of the torn stone has an even and smooth surface, which makes the laying process more simple and convenient.

Blocks and slabs of ragged stone do not grind and do not grind. As a result, the surface finished with this material looks like an old wall of a medieval castle or part of a real granite rock.

To give the surface the most natural appearance, the tiles of the torn stone are selected in different sizes. As a result, the seams between the individual stones turn out to be similar to cracks in the rock. In modern interior decoration "antique" is very popular. Today, external and internal decorative lining with a ragged stone can often be found in various places: in the office, restaurant, shop, in the living room or kitchen of the city apartment.

But most often the finish with a ragged stone is used in suburban private houses when decorating a living room, kitchen, bathroom, or bedroom. Facing of torn stone perfectly combined with parquet, oak floor, artificially aged wooden furniture and decorative forged elements.

Important point: if you decide to use a torn stone in the design of the room, do not forget to take care of sufficient lighting. Otherwise, the interior will look grim.

Ragged Stone: Advantages

Let's start with the main thing - universality. The material, as already mentioned above, can be used for both external and internal lining.

But this is not the only advantage of a torn stone, it has a number of positive qualities:

- Facing this material significantly increases the soundproofing of the room.

- The material has a small weight, compared with natural stone, it is easier and easier to work with.

- Ragged stone can be used to make surfaces from plasterboard.

- Decorative stone is a fire-resistant material, it can be used in premises, which are subject to increased fire safety requirements: in hospitals, cinemas, airports, etc.

- The torn stone is not corroded.

- Wide range of colors, shades and textures.

- The decorative stone does not need constant care, it is durable.

Varieties of torn stone and their application

Most manufacturers produce several types of lining "torn stone". It can be:

tile

panels

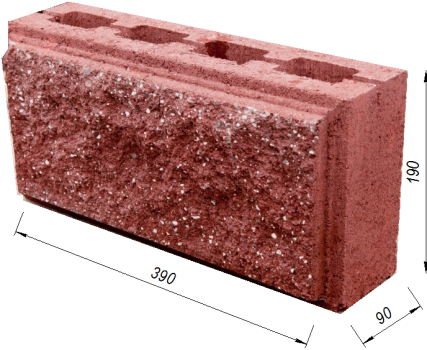

brick

block

The panel and the tile of the torn stone are most often used for facing the elements of the building interior, as well as the facade and the socle. This material is perfectly attached to almost any surface with the usual glue used for mounting ceramic tiles.

Important point: if you want to tile the surface of a surface that is constantly exposed to moisture, for example: the base of the house, the pool, the bathroom, then the torn stone before the beginning of the work must be impregnated with a special waterproofing compound.

Facing brick torn stone is used for facing the facades of buildings, from it are built interior partitions, the brick is also used for decorating walls inside the building, decorating columns, fireplaces, fences, etc.

A wide variety of colors, shapes and textures make it possible to choose the most suitable variant for interior decoration of any residential building or premises - be it an office, a private house, or an apartment. Ragged stone is also often used for the construction of fences and fences.

For convenience manufacturers produce special elements for fences and fences:

- Facing front block.

- Half of the cladding block.

- Block corner.

- Blocks ragged stone for the pillars - "ring".

If you use different types of decorative stone masonry, alternate rows of smooth and torn surfaces, use material of different colors and shades, then you can get an exclusive design - beautiful and durable.

Ragged stone: styling methods

When carrying out external cladding works, the torn stone can be laid in several ways: dry and wet. In this case, the dry method is considered to be more reliable, but at the same time, more labor-consuming and expensive, in comparison with the wet method. The technology of laying a ragged stone dry includes the following works:

- Installation of heat-insulating and vapor-insulating material.

- The device is for a crate.

- The device of horizontal marking.

- Fastening of material.

- Fixing slits with special dry construction mixtures.

Dry method is advisable to use for the construction of small fences, with the help of it, for example, lay a torn stone for fence, or when laying a curbstone.

https://www.youtube.com/watch?v=lh6r5nVfvpE

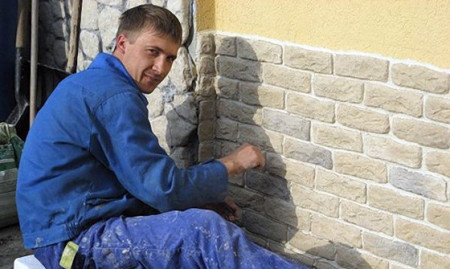

A wet method of laying a torn stone is most often used in finishing the overall and high concrete monolithic structures. This method of laying is considered to be simpler, since in this case it is not necessary to carefully adjust the adjacent elements of the facing. Laying the tiles with a wet method is done in the following sequence:

- Substrate preparation: leveling, dust removal, priming.

- Apply a small layer of glue on the back of the tile and the base.

- Fastening the tiles to the surface.

- Grouting joints between tiles.

How to lay a ragged stone: a step-by-step guide

Below we will consider the technology of laying decorative stone in more detail.

First you need to prepare materials and tools:

- Bulgarian or hacksaw for cutting tiles.

- Joiner's chair - you need to cut the tiles at the right angle.

- Putty knife. It is necessary for application of an adhesive compound. It is recommended to prepare three spatulas of different sizes: small (7 cm), medium toothed (15 cm) and medium level spatula (15 cm).

- Mixture for putty. Needed to seal seams at the corners and joints.

- Decorative paint. It is necessary to mask possible tiles of the tile and to paint white seams after grouting with putty.

- Varnish for finishing joints (applied after paint).

- Sponge (you can use the usual kitchen). With its help it is convenient to handle joints and corners.

- Several paint brushes of different sizes.

- File, sandpaper, chisel - will be useful for precise fitting of the elements to each other.

- Glue for tiles.

- Building level.

- Building pencil.

- Liquid Nails.

- Electrodrill or mixer for mixing glue and putty.

preparation of the substrate before laying of the finishing material

The surface under the lining should be clean. If the cladding works are carried out in hot weather, before laying the tile the base should be slightly moistened by sprinkling the wall with water. If the surface absorbs moisture very much, it must be treated with a primer.

After the lining material is unpacked, before laying it is recommended to lay out a preliminary pattern from the tile on a flat surface. Thanks to this simple operation, you can significantly simplify the selection of different elements in terms of thickness, color and texture. If there is such a need, you can adjust the elements among themselves for a denser docking.

The area that needs to be clad is divided into several small sections - roughly - 5 rows. Counting the area of the sites, do not forget to take into account the distance between the seams (about 1-1.2cm).

Before beginning the laying of the material, consider the material, since very often the visual perception of the finished lined surface depends heavily on which side the material was laid. Therefore, when buying a torn stone, be sure to ask the seller how to properly install.

After this, dilute the adhesive mixture with water and stir with an electric drill or a mixer until a uniform consistency is obtained. In the process of laying, take care that there is no coincidence of the joints of the tiles. Facing the facade must be done under the level. If you need to leave a free space, for example, under the switch, make markings on the tile, and carefully cut off excess with a grinder or saw. Cutting is best on the contour of the texture, because at this point the thickness of the material is smaller.

When the tiling is finished, the joints are sealed with all corners and corners of the joints, after which the putty is painted in the tone of the torn stone. The paint is applied only after the putty completely dries. All painted places must be opened with a water-based varnish. This will help improve the resistance of the ragged stone to moisture.

Some recommendations on the laying of decorative stone

The tips below will be useful if you decide to make the lining yourself a torn stone and do not have the appropriate experience.

- Do not make the seam between the tiles too wide.

- If you want to work with facing panels, apply a primer to the base for a more reliable and durable fixing of the material.

- Laying must be done from the bottom up.

- Laying a torn stone inside the premises is best done at a temperature not exceeding 25 degrees Celsius.

- During the laying process, rowing is not necessary. However, tile laying chaotically is also not worth it - maintaining a certain order will give the finished surface more slenderness and beauty.

- Do not mount the torn stone to the surface with silicone, because due to the temperature drop the tile will begin to fall off.

- If the cladding works are carried out in the basement, bathroom or kitchen, the finished surface must be treated with antiseptic composition in order to avoid the reproduction of fungus and mold.