The selection of pipes for water-floor systems must be approached with responsibility. From the choice of the type of pipes laid in the system and a simple calculation, the final result of the heating cover will depend. A good combination of "snake" and "snail" confirms that you are on the right track.

Content

The main technical parameters of pipes of water-floor systems

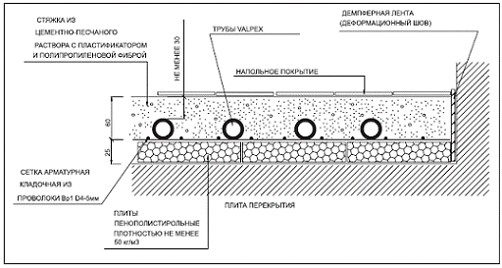

The system of "warm floor" of water consists of a heat-insulating layer, collectors for connection to a heating system, a pump for water circulation and pipes (polymer or metal-plastic).

If you intend to install a warm water floor, the primary problem will be the choice of pipes. Which pipes for a warm water floor are preferable to choose?

We will show that the main technical characteristics of pipes intended for installation of a field system are the following parameters:

• Outer diameter and wall thickness

• maximum carrier temperature

• the presence of an oxygen barrier

• volume of heat carrier per 1 m.

• maximum bending radius

• fabrication material

• operating pressure

• Weight m / kg.

Naturally, the practical advantages of pipes for the water floor are of primary importance when choosing: the features of rational installation and installation, impact resistance and durability.

The selection of the diameter of the pipes, as well as the location of the installation, depends on the expected amount of heat intended for heating. When calculating heat loss: the thickness of the walls of the house, the number and quality of the windows and the temperature.

Which pipes for floor water exist

Based on the recommendations for water systems of the warm floor, the pipes must provide the following conditions:

• withstand operating temperature 50-60 ° С

• be mechanically strong when exposed

• do not lose their performance in case of a single freezing

• be strong in bending

• Extinguish acoustic noise during operation

• Avoid exposure to corrosive media

• be operable for a long service life (50 years).

To buy pipes for the warm floor, you need to pick up their footage for installation.

For the "Warm Floor" water system, the following types of pipes exist:

• metal-plastic

• polyethylene PE

• corrugated steel

• Copper.

To understand the question: "Which pipe is better for a warm floor?", It is necessary to study the technical characteristics, operating conditions and the ability to perform the functions of the transport main, as well as the connection methods declared by the manufacturer.

Choosing pipes for the underfloor heating system

metal plastic pipes

Technical characteristics of metal-plastic pipes:

Round section with an external diameter from 16.0 to 20.0 mm and an internal 12.0 mm wall thickness of 2.0 mm. The maximum operating temperature range is 95 degrees, with an allowable short-term temperature of 120 degrees. The maximum working pressure can reach 10 bar. The minimum bend radius is 7 mm.

Metal-plastic pipes are supplied by the manufacturer in coils. For installation of 1 square meter of a warm floor, an average of 3 meters of pipe will be required.

Metal-plastic pipes for the warm floor are distinguished by:

• smooth surface inside with an insignificant coefficient of roughness, ensuring minimum losses of water flow

• Absence of traces of corrosion and salt deposits

• dampening of water and vibration noise

• Absence of conductivity

• light weight, complete tightness and connection reliability

• high environmental indicator.

Metalloplastikovye pipes can be confidently called the best for the warm floor.

Price of pipes from metal-plastic REHAU, Valtec for the water floor is insignificant.

Experts advise that for a metal-plastic pipe with a diameter of 16 mm make a contour of 80-100 m. For a pipe with a diameter of 20 mm, the length of the contour will be 120 m.

Helpful Tips

Metal-plastic pipes are distinguished by a slight bend radius, which allows direct connection with the use of special springs. With an insignificant weight of pipes and the convenience of installation, additional saving of fittings is added. Metal-plastic pipes are easy to lay by hand.

ways of joining metal-plastic pipes

There are the following methods of joining metal-plastic pipes: split and integral. The expediency of using the connection method is dictated by the parameters of the system and the calculation of the number of materials necessary for installation.

polyethylene pipes

The most budgetary choice for systems "warm floor" are polypropylene and pipes made of cross-linked polyethylene. The production technology of cross-linked polyethylene provides the polymer with a high, widely mesh three-dimensional mesh.

Marking of polymer on pipes has the following designations:

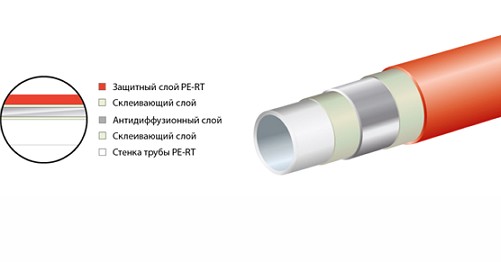

• PE-RT - cross-linked polyethylene based on polymeric compound with increased heat resistance

• PE-Xa is a polymer formed by heating using peroxides

• PE-Xb - the polymer was formed using a catalytic agent and implanted with silane

• PE-Xc - electron bombardment was used to create the polymer

• PE-Xd - polymer was obtained as a result of the application of nitrogen technology.

Performance characteristics and parameters of polyethylene pipes are rated for temperature up to + 90 ° С, maximum (emergency) load + 100 ° С, pressure 6-8 bar. Sufficiently high operating temperatures ensure the thermal stability of PE-RT polyethylene.

For the installation of the system "Warm floor water" it is recommended to use the type of pipes: multilayer pipes made of PE-RT polyethylene based on DOWLEX.

Helpful Tips

If the marking on polyethylene pipes is empty for you, you should not be upset. In any online store, a knowledgeable consultant will give advice on this matter.

To calculate the flow of selected pipes, it is recommended to use the calculator in the on-line mode. As a result of a simple calculation, data on the length of the stacked pipes will be obtained, according to the chosen installation method.

Calculate the length of polyethylene pipes can be manually, using the formula L = S / N x 1.1,

where:

S - area of the circuit (m2)

N - stacking step

1.1 - the coefficient. pipe stock (10%)

steel corrugated pipes

Pipes for a system of stainless steel are distinguished by a high coefficient of thermal conductivity, compared to metal-plastic or PE pipes. Naturally, the price of steel corrugated pipes for the floor system is also high.

Of course, the best and most effective choice can be called copper pipes, which by thermal conductivity surpass other types. The strength and reliability of copper pipes, rapid heating and the absence of corrosion and plaque are perhaps the main parameters. However, the "price of the issue" in most cases is the brake on the acquisition of copper pipes for the water floor.