To build a welding machine by one's own hands, one will not be enough, and to be precise, it's not enough. Therefore, in a natural way, a thought creeps into your head,

"Is it possible to assemble a welding machine at all?" It is possible and even necessary!

Content

What is necessary for assembling the welding machine

To assemble the welding inverter by one's own hands, it is first necessary to determine the electrical circuit, which will correspond to the necessary operating parameters of the apparatus.

The circuit is selected on the basis of welding current and component parameters, from which it is planned to assemble the welding machine. Recall that the maximum level of welding current for welding machines, can be set in the working range from 40 to 130 A.

The welding current capacity in this case will allow welding of parts with an electrode of 3 mm. As a scheme and element base for a welding machine, it is recommended to use Soviet-made radio components: diodes, thyristors, resistors, transistors, capacitors, chokes, and also "not broken" ready-made transformers.

As practice shows, tested and tested by the centuries, the schemes will not in the future require a complicated adjustment and adjustment of bench equipment.

It will not hurt to also look through the magazines "Amateur Radio" during the 1960s, where the basics of knowledge on electrical engineering for thirsty and fans of radio electronics are available, and most importantly.

If you consider the assembly of a welding inverter manufactured in "Made in China" factory, at a price of up to $ 500, then you can find electronic elements familiar from the era of the USSR. Ah, that's where the "droveshki!"

The scheme, borrowed once, was adopted by Chinese specialists who established the serial production of welding machines. So why not collect the welding inverter yourself, buying for the penny the necessary elements.

What elements should a welding machine consist of?

The welding machine is designed to work with electrodes up to 4-5 mm and has a significant current margin.

The main technical characteristics of the welding machine:

• maximum operating current from 220 to 250 A

• The power supply is 220 V household electricity

• presence of no-load current up to 30 A

• welding current control from 30 to 220 A.

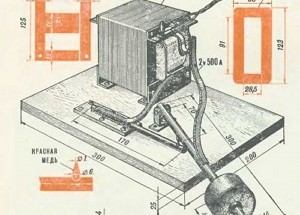

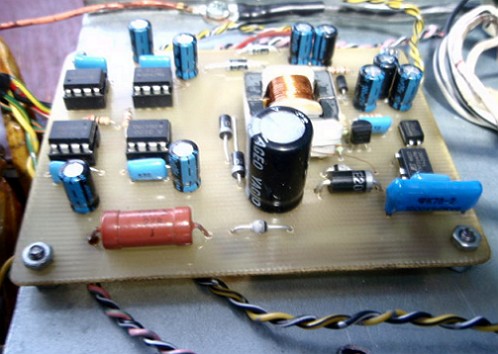

The welding machine, which is assembled by one's own hands, should consist of a power supply unit and the electronic unit itself. The design of the electronic unit needs to be considered considering the dimensions and layout of the mounting and installation of the output transformer, as well as the cooling elements.

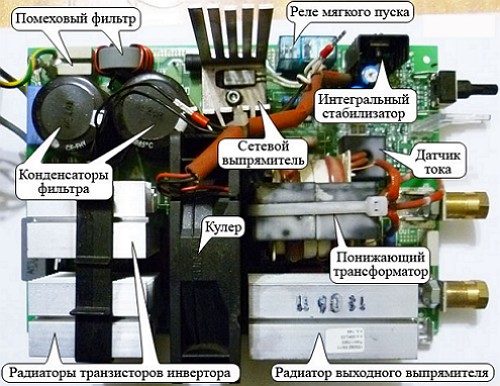

Structurally, the welding machine, assembled independently, consists of blocks:

• power supply unit

• Rectifier unit

• Inverter unit

power Supply

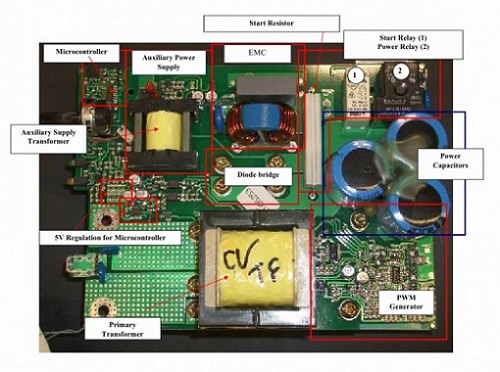

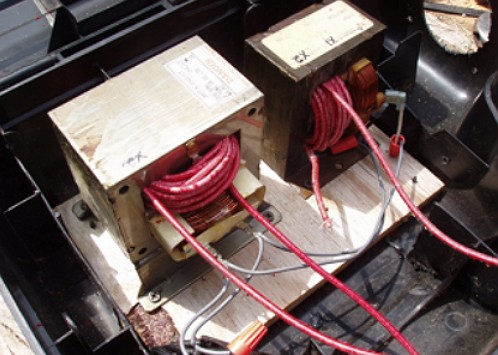

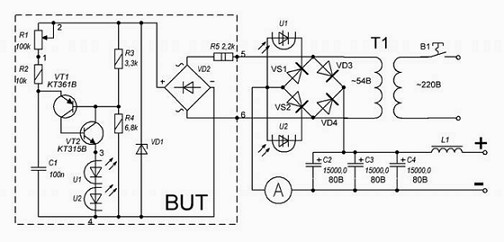

The main element of the power supply of the welding inverter is a three-phase transformer with two windings. It is recommended to connect the primary windings on the magnetic core by the type "star" or "triangle". Such types of connection are used for the device in case of its supply from the consumer's network with voltage 220/380 V.

If you plan to connect the device to a single-phase 220 V network, apply the connection of the windings of the extreme rods of the magnetic core by a parallel-counter connection.

The connection scheme of the secondary winding must be fixed in an open "triangle". For manual winding, the value of the windings of the transformer windings is calculated.

So, for example, for a power supply designed for a current source of 250 A, a scheme will be applied in which:

• for the primary winding of the transformer, which is formed independently, the primary winding will consist of 100 turns of the PEV wire with a cross section of 0.3 mm.

• for secondary winding 2, 15 turns of wire with a cross section of 1 mm will be used.

• for the secondary winding 3, 15 turns of PEW with a cross section of 0.2 mm will be used.

• For the secondary winding 4 and 5, 20 turns of wire with a cross section of 0.35 mm are used.

The winding of the transformer is carried out on the ferrite core Ш7х7 or 8х8.

The design and the power unit, including the transformer, must be in a certain temperature regime, so it is necessary to provide for a fan of 220 V to 0.13 A. For these purposes, fans from older PCs Pentium 4 can be used.

principle of operation of an inverter circuit

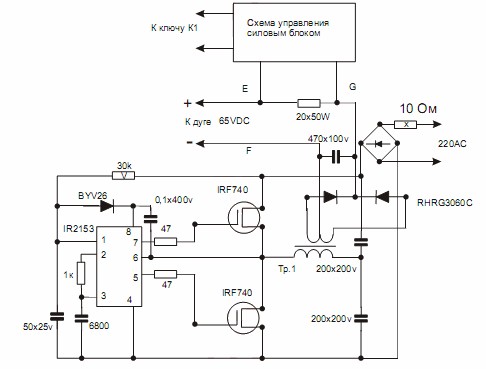

According to the scheme, the inverter's operability is carried out from the 220 V network, starting with rectification by smoothing capacitors.

Then the received pulse is fed to the transistor switches, which transfer the DC voltage to the high-frequency variable. High-frequency alternating voltage is applied to the transformer ferrite.

Thus, the main stages of energy conversion in the inverter are:

• rectification of the AC input voltage 220 V

• Conversion of a constant voltage into a high-frequency variable

• Reduction of high-frequency voltage

• Undervoltage rectification.

rectifier unit

The inverter circuit consists of powerful transistor-switches, switching with a frequency of up to 80 kHz. In order for the transistors to work, it is necessary to apply a constant voltage received from the rectifier. As a rectifier in the scheme of the welding inverter is a diode bridge, a signal that is smoothed with filters by capacitors.

This is the basic step of converting the input voltage. Transistors switch at a frequency of up to 80 kHz, so the operation of the step-down transformer is carried out at the same frequency.

It should be recalled that on the filter capacitors the voltage exceeds the voltage with the output of the diode bridge by 1.41 times. After passing the diode bridge, the pulsating voltage of 220V will be accumulated by capacitors according to the formula: 220V x 1.41 = 310.2 V.

Limiting the operating voltage to 250 V will allow to obtain 350 V at the output of the filter, which is what it was required to obtain. Due to the high frequency, it is possible to reduce the weight and dimensions of the transformer.

On the rectifier unit board, there is a place for installing an intermediate relay and a cooling fan.

Welding inverter assembly

The case of the welding inverter can be made of thin sheet steel, textolite or vinyl plastic. Excellent, if the household master has a ready-made housing from any device.

Assemble the main assembled units of the inverter and secure them. On the front side of the case you need to install an LED indicator and a toggle switch for switching on, as well as an alternating resistance for adjusting the power of the welding current.

The housing must also have clamps for welding cables.