Window grilles have been and remain one of the most inexpensive and reliable ways of passive protection against penetration into the house. For a long time gloomy standard products of Soviet times from massive armature have become a thing of the past. Indeed, in many people the grilles on the windows cause a negative reaction. But if you show a little creativity in their manufacture, the grilles on the windows will not only not spoil the facade of the house, but will also become a worthy element of the decor.

Content

Why lattice?

Today, the owners of the apartments install expensive anti-burglary locks on the windows and doors. Experienced thieves-burglars do not even try to open them, but go in an easier way - they break open the window frame or door. The entrance to your housing can be secured as much as possible by installing massive metal doors with a good lock. But the windows are more difficult - except to install metal shutters. You can, of course, install an alarm system on the windows. However, this, firstly, is expensive, and secondly, the alarm can be more harm than good.

For example, a thief does not suspect anything about the installed alarm system, and is quietly engaged in his own business. While law enforcement officers or security guards come to the signal, it can damage window frames, windows or doors. The high-quality grille on the windows can one by itself diminish the fervor of such citizens and make them look for an object easier.

Statistics say that in more than 90% of cases, attackers choose a target that is not protected by grids. The remaining 10% can be attributed to professionals, which no lattice, armored doors and alarms will not stop. But getting under the sights of such a "specialist" ordinary citizen is unlikely to be lucky, so that the installation of gratings on windows can be considered a completely reliable method of protection against penetration. But we are a bit distracted - let's see what the modern market offers the consumer.

Grille-tube

The most simple and neutral way to protect window openings. It is about the roller blinds known to all. They are not striking, do not attract attention, do not spoil the interior. And at the same time significantly reduce the risk of penetration through windows. Roll-up grilles made of steel or aluminum strips do not prevent free air circulation - at night you can leave the window open, lowering the roller shutters. From the viewpoint of fire safety, the shutters are much safer than stationary grids, which can turn into an insurmountable obstacle in case of fire. However, this option is not liked by all because of the fact that in the expanded form the shutters are reminiscent of a dead wall. But the assortment of window lattices is so great that the most demanding buyer will necessarily find what he needs.

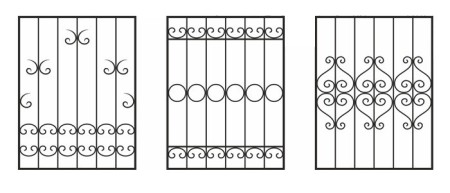

Forged gratings on windows

They do not differ in functionality from old massive gratings - they are just as "leaky", they can not be folded, but they do not create a sense of imprisonment. Quite the contrary. Forged lattices are graceful and beautiful. If we talk about forged products, then they are not at all similar to gloomy constructions made of fittings with poorly cleaned traces of welding and rust stains. These are delicate items that do not cross out the windows, but complement them. With the proper evaluation of the design, they will become a worthy decoration of the facade. And, in addition, it is not necessary to make forged lattices stationary. You can order sliding structures, which are much preferable in terms of fire safety. The main drawback of forged gratings is the laboriousness of manufacturing. Art forging is very expensive, and afford such a design can not everyone.

Welded structures

Excellent option in the ratio of price / quality. In appearance, they, of course, are inferior to forged products, but not much. The main difference in design is that forged lattices can be volumetric - convex, semicircular, etc., and welded - flat. But even in this case, masters can make a real masterpiece from an ordinary grate, decorating it with drawings and ornaments. In terms of functionality and reliability, such designs are in no way inferior to forged products, the main difference is price.

Conventional metal grilles

Here everything is simple without excesses. The usual grille on the window. This option for people who just want to protect themselves from hacking, and the decorative component of the product does not play any role for them. These are inexpensive, reliable and practical products. However, even in this case, in terms of assortment, not everything is so sad - you can buy swinging or sliding designs.

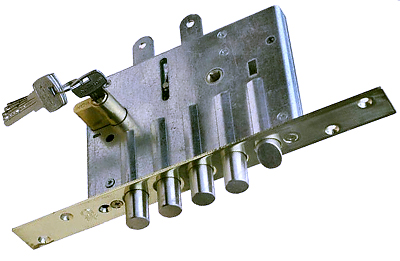

Locks for window grilles

Virtually all types of gratings (except stationary structures that are installed on windows and do not open) are equipped with locks. There is also something to choose from. The simplest and cheapest option is a padlock.

It is easiest to open it to the owners, and, alas, to thieves. Mortise lock type "coupe" is much better protected from hacking.

A bolt lock, which can be opened and closed only from the inside, is one of the most reliable.

And if you install several types of locks simultaneously on the grid, this will reduce the probability of penetration into the house through the window to a minimum. Of course, quite a lot of people continue to be skeptical about window grilles as a method of defense, motivating their position by the fact that a technically competent criminal armed with modern tools will crack them without difficulty. In part this is true, but modern window grilles are very strong and shockproof, and the sense to spend on their manufacture and installation is still there.

Making gratings on the windows with your own hands

As part of this publication, we do not set ourselves the detailed instructions for the manufacture of window grilles, we will limit ourselves to general advice and recommendations. Make the window grill yourself quite by the forces of a man who can work with a welding machine.

One of the simplest options is to insert the ends of the reinforcement into the window opening, then weld the bars to them, then decorate the product with purchased forged products. The most common decorative elements for window grilles:

- Monogram.

- Baskets.

- Peaks.

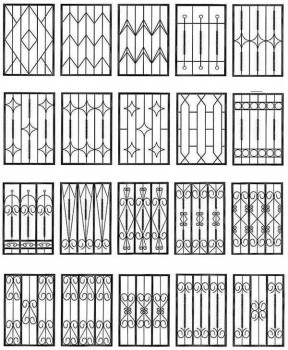

The options for the design of window grilles are shown in the picture below:

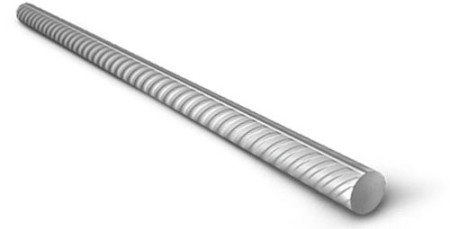

For the self-manufacturing of the window grilles, it is necessary to stock up some quantity of rolled metal -

metal stripe

rods

First you need to measure the window opening. Then make at least an approximate drawing of the future grid. Depending on the design, the lattice bars are bent or laid on each other and welded at the joints. On the perimeter of the lattice, a frame is made from a metal corner.

The gaps between the bars of the grid must be such that even a child can not squeeze between them. But you should not also make something out of the grid like a mosquito net. The optimal distance between the rods is 15-20 centimeters. After the grid is ready, it can be decorated with forging elements. The places of connection of decorative details with rods are closed with special crimping plates, which makes them invisible. Of course, for the protection of housing the simplest construction will do, but in combination with decorative elements, even a rough homemade product will become an element of decor.

If your money is tight, you can make a simple welded grate yourself, if you, of course, know how to use a welding machine. The design is simple enough reliable, not inferior in this respect forged products. The peculiarity of simple welded lattices is that the rods are usually welded in the form of simple geometric figures located on the web symmetrically to each other.

The main elements of welding grids:

- The arc, the oval.

- Whole rings or parts of them.

- Details in the form of the letter "S".

All the details look pretty neat, serve for a long time and reliably. Welded grilles, thanks to the democratic price, reliability and ease of installation are in good demand.

Sliding grille with your own hands

It is difficult to make such a grate, but it is still possible. The difficulty lies in the manufacture of the mechanism, because the lattice sections must not only move, but also fold.

Sliding grilles on the windows include the following parts:

- The frame, which is the guide for the grid and takes over the weight of the entire structure. In the frame there are grooves on which the rollers go.

- Lattice, divided into several sections, which are movably connected to each other. The rollers are fixed on the sections at the top and bottom.

To make a folding mechanism, you need to prepare two plates for each gap between the bars of the section. In the plates, you need to make three holes - two at the edges and one in the middle. Connect the plates together with rivets, since they must remain movable. You need to connect first crosswise, and only then at the edges. Such mechanisms need to do three things: up, down and in the middle of the grate. At the point where the plates are connected by the central hole, you need to weld a vertical stand. This operation is done with all three mechanisms. During the fastening of the elements, the mechanisms must be moved apart.

To under the influence of their own weight, the leaflets do not begin to warp, a guide is installed along which the bearing slides. The guide is mounted on the edge of each leaf. The lock or latch is set at the discretion of the owners. For this purpose it is possible to use bolts or a conventional door lock.

Materials for window grilles

For the manufacture of gratings, the following can be used:

- A metal rod.

- A metal square.

- Combined profile.

- Metal strip.

You can save a little by using a metal strip, but, although it is cheaper, it is inferior in reliability and quality to other materials. In addition, products from the metal strip are not distinguished by beauty.

From a metal square or rod, you can make a rather interesting window lattice.

Most often, masters use 16 x 16 and a rod with a diameter of 20 millimeters. Very strong and durable lattice from pipes are obtained. However, most often pipes are made of frames, and other materials are used to make the lattice web. As a rule, welded gratings are a combination of different materials.

Installation of gratings on windows

https://www.youtube.com/watch?v=4cO2RgKIXUY

Installation of window grilles is made in two ways:

- In the window aperture.

- In the overlay on the window opening.

If the house is brick or concrete, then the ends of the window openings in pre-drilled holes are clogged with pins from the reinforcement. The ends of the pins should protrude a few centimeters. The finished grid is welded to the protruding parts of the pins.

In the log cabins, special eyelets are attached to the window frames. Through the holes in the lugs, the structure is screwed to the ends of the window opening with the help of screws.

In houses of glued beams, window grilles are installed in the overlay on the window opening. To do this, first make holes for screws in the wall. To ensure that the entire structure is held as tightly as possible, it is bolted through the bolts. This method is the most reliable, but it can not always be used - it all depends on the thickness of the walls and the material from which they are built.

The window grid can also be installed in this way:

Mark in the window aperture of the place where the grid will be fastened with the help of pins. Make grooves with a perforator. Install the rods, starting from the bottom and gradually rising upward. Weld the finished grate. This is one of the most reliable ways of fastening. If the grid is provided with loops, it is necessary to work very carefully with welding, so as not to damage them. After finishing the welding work, the grid must be painted. In the process of painting, special attention should be paid to welding seams, as they quickly rust.

With the help of welding, the sliding grilles are also fixed, but it should be borne in mind that this design also includes the runners on which the doors move. Sliding design is much easier to crack than stationary, so you still need to think through additional protection against hacking. The skids of the sliding grilles are concealed with various decorative elements. The easiest way to do this is by hanging out the window plants in pots.

Another option for self-installation - removable grilles on hooks. But this design is most, as they say, "for beauty", rather than for real protection against penetration.

Also this method of fastening is suitable as a temporary one - if soon it will be necessary to replace the window. After the replacement, the grid can be fixed in a more reliable way.

One of the most reliable ways of fastening window grilles is inside the building.

This type of fastening is often used in banks. Such a grating can not be hacked unnoticed, unlike an external one.