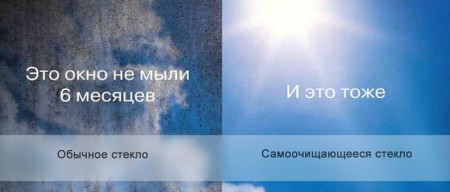

The most unpleasant moment in the maintenance of windows is their washing outside, because it is outside the window that pollute the most. The window becomes opaque, ugly. We have to open the window and expose ourselves to an unpleasant, and sometimes unsafe, washing procedure.

The idea of creating a glass that does not need to be washed appeared long ago - back in the 60s of the last century. But then it seemed fantastic and not feasible, because at that time there was no technology that allows you to apply a coating on a clean glass that has self-cleaning properties. In addition, the coating should be durable, completely transparent and do not exfoliate from the glass surface. Developers managed to solve this problem, and several years ago self-cleaning glass appeared on sale.

Content

Self-cleaning glass - what it is

On ordinary glass in the production process, a superfine transparent coating is applied, based on titanium dioxide. This element has long been used in the industry as a photocatalyst. The coating has the ability to self-clean. Apply it to the surface of the glass at a very high temperature - about 650 ° C. After applying the coating can no longer be separated from the glass surface, its service life is unlimited, if you believe the manufacturers.

The coating does not abrade, does not scratch, it does not have any special requirements for storage, transportation and operation.

Since glass and self-cleaning coatings are a single whole, it can be damaged, like the glass itself, with sharp objects, or, for example, an abrasive cleaner or steel wool.

advantages of self-cleaning glass

The name speaks for itself - you do not really need to clean the self-cleaning glass. And this is saving time, money, effort, and, of course, improving the safety of building operation. Self-cleaning glass, although it costs an order of magnitude more than usual, after several years pays for itself, as the costs of washing windows and glass facades are reduced to a minimum. Self-cleaning coating has a mirror effect, gives the glass different shades, so for architects, self-cleaning glasses are attractive for their ability to decorate the appearance of the building.

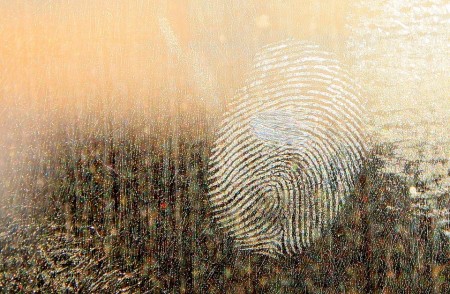

what kind of pollution can self-cleaning glass

The coating perfectly copes with pollution of organic origin, for example, with bird droppings, woody juice, pollen, fingerprints, and, what is especially important for large megacities, products of incomplete combustion of cars, forming a thin oily film on the glass surface, which is extremely difficult. Perfectly removed from the surface are such particles of inorganic origin as cement, road, chalk dust and stains remaining after hard water.

The principle of the self-cleaning glass

Occurs in several stages. At the first stage, the mud decomposes into components under the action of the solar ultraviolet. Here it should be noted that this is a completely natural process: in nature, all organic matter under the influence of ultraviolet and oxygen decomposes into constituent components, gradually turning into water and carbon dioxide. The coating of titanium dioxide only accelerates this process several times, playing the role of a chemical reaction catalyst - the dirty glass becomes clean.

The second stage of cleaning the surface is washing away the decomposed residues of dirt and various inorganic water pollution. The usual rain perfectly copes with this task.

Glass with a self-cleaning coating, in contrast to the usual, is hydrophilic, that is, the water on its surface is not collected in the form of droplets, but evenly distributed and drains over the entire surface, along with removing all the dirt. The hydrophilic surface dries very quickly, after which there are no stains, no divorces, no salt stains (if the water is stiff).

Important point: after the glass was installed, it needs about a week to fully activate the hydrophilic properties under the influence of ultraviolet radiation.

does the self-cleaning coating work in cloudy weather?

Since for the normal operation of the coating, a very small amount of UV radiation is needed, so the effect of ultraviolet radiation on the mud will be effective also on cloudy days. Therefore, the self-cleaning coating will work equally well both on the south and the north side of the building. The hydrophilic properties of the coating are preserved even at night.

where self-cleaning glass is used

Self-cleaning glass is suitable only for exterior glazing of buildings. This is due to the fact that for its full-fledged work, ultraviolet and rainwater are needed.

It can be used for glazing windows, facades of buildings, roofs, winter gardens, etc.

Do not install self-cleaning glass in places where rainwater can not reach, for example under canopies and visors.

The most justifiable from a financial point of view installation of self-cleaning windows in those parts of the building where it is expensive or physically difficult to ensure regular cleaning of the facade or windows. We are talking, first of all, about high-rise buildings, glass roofs, anti-aircraft flashlights, greenhouses, etc. However, it is possible to install self-cleaning glass in ordinary apartment windows.

For added security or, for example, penetration protection, the glass can be quenched or laminated. Among other things, self-cleaning glass can be combined in a double-glazed window with other types of glass, for example with energy-saving glass (about it below), to improve the sound and heat insulation properties. Glasses with a self-cleaning coating can be bent, and used for glazing convex structures.

what does self-cleaning glass look like

At first glance, such a glass is no different from the usual one. There are only a few minor points that make it possible to distinguish self-cleaning glass.

First: on the surface of the coated glass, the sunlight is more noticeable, since the coefficient of sunlight reflection is 14% for it, for ordinary glass, only 8%. Simply put, self-cleaning glass is more "mirror".

The second: if you look at the light reflected from the surface at an acute angle, a slight bluish tint becomes visible, thanks to which the glass has a very attractive appearance.

Can I buy self-cleaning glass with a sun protection function?

Recently, a multifunctional blue glass was on sale. In addition to the self-cleaning function, this glass provides good protection against excessive UV radiation. Usual glass passes up to 62% of ultraviolet, multifunctional - only 15%.

Such glass is advisable to use in places where it is necessary to simultaneously ensure the surface cleanliness and protection from the sun, for example in greenhouses, gardens and roofs.

when it is necessary to wash self-cleaning glass

This point should be considered as a comparison with conventional glass. The need for washing self-cleaning glass is many times less. However, this does not mean that such a glass will not have to be washed. For example, it will have to be washed on its own, if a very thick layer of dirt has appeared on the surface, and ultraviolet simply can not "get through" to the surface, and the glass can not clean itself.

Another option - for a long time it did not rain. How long should the drought last for the glass to stop functioning is difficult to say. It depends on many factors: for example, the location of the building is an ecologically clean area or industrial zone, the presence of a nearby motorway, etc.

is it difficult to clean self-cleaning glass

Very easy. It is enough simply to coat the surface of the hose to completely resume the process of self-cleaning. If there is such a need, you can use a soft cloth and warm soapy water. If the contamination is very severe, it is permissible to use non-abrasive liquid detergents.

Energy-saving glass

As mentioned above, self-cleaning glass is used as a part of double-glazed windows with other types of glass to enhance the functionality of windows. One such type is energy-saving glass.

that is energy-saving glass

At first glance, such a glass, like self-cleaning, does not differ from the usual one.

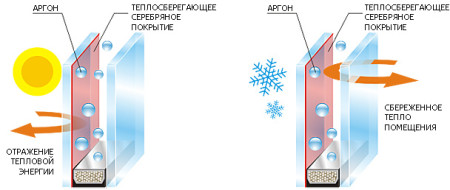

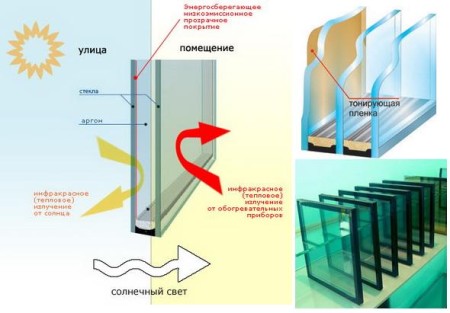

A subtle, inconspicuous coating is applied to its surface, allowing thermal radiation to be reflected inside the room, and at the same time, letting it pass from the outside.

There are several types of energy-saving glasses:

I-glass. It is supplied with a hard coating based on tin oxide, which is applied to the surface of the glass during production.

K-glass. It uses a soft coating based on polymers and silver, which is applied at the request of the customer already after the full manufacture of the insulating glass unit.

I-glass is more comfortable and in operation, and not only because of the choice of the customer - to apply a coating, or not. The I-glass coating has very good thermal characteristics, which make it possible to ensure a temperature on the surface of the glass + 14 ° C at a street temperature of -26 ° C. As for K-glass, under the same conditions, the temperature at its surface will be only + 11 ° C.

minuses of energy-saving glass

In addition to the obvious advantages, energy-saving glass has several drawbacks, which must be taken into account when buying and in service.

No manufacturer today can accurately say how long will the energy-saving coating of glass. And although you can hear the high-profile promises of thirty years of impeccable service, they are based only on the results of benchmarking the samples of coverage.

The soft I-coating has more shortcomings in terms of practicality. It is very easy to damage, so the coating is applied to the inside of the insulating glass unit. The soft layer is susceptible to oxidation, so it must be in a sealed environment, otherwise iridescent stains will appear on the surface over time.

If the soft-coated glass is stored without adequate packaging for more than a month, the energy-saving layer begins to decompose. Therefore, if there are divorces on the double-glazed windows, then the manufacturer re-used the expired components. Another drawback of I-glass is a slight deterioration in the light transmission capacity of the glass unit.

The above disadvantages do not apply to glasses that have K-coating, their main disadvantage is the high cost, due to the need to pour gas inside the glass unit and increase the thickness of the glass.

marking of energy-saving glasses

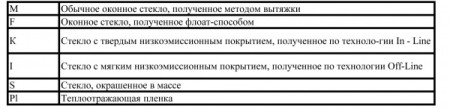

Energy-saving glasses of both types differ from conventional ones not only in their characteristics, but also in the presence of special markings.

Quite often there are cases when an inexperienced seller who does not understand the intricacies of production to the buyer tries to sell goods of a completely different category for a large price. At the same time, a cheap double-glazed window is issued for an expensive energy-saving model.

When you receive the ordered window or when you choose in the salon, you need to know what it means to mark this or that. So, the most common glass, which was obtained by the drawing method without any additional functions, is labeled with the letter "M". The package, completed with a glass of increased hardness, is marked "F". Depending on which energy-saving coating is applied to the glass, the marking will be "I" or "K", respectively. The presence of any type of energy-saving coating is indicated by the symbols "PL", and when the glass was painted in mass, there will be a letter "S".

https://www.youtube.com/watch?v=eA6pwU8A390